High Carbon Graphite Electrode(RP HD HP UHP) Graphite Electrode Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have full set of production line for graphite electrodes. Our products are characterized by superior compact structure, good electrical and thermal conductivity, high resistance to oxidation and corrosion in high temperature. The regular power graphite electrodes are used in metallurgy industry for refining, such as EAF furnaces of steel plant and other applications. As one of the most professional graphite electrode manufacturers in China, passed ISO9001:2000 certified. We're glad to quote you a most competitive price according to your specification.

2.Main features of Graphite Electrodes:

1).Good electrical conductivity

2).High resistance to thermal shock

3).High mechanical strength

3. Graphite Electrodes Images:

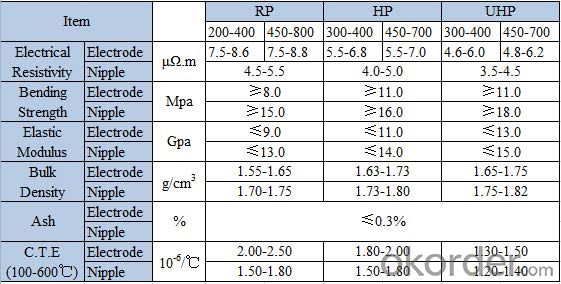

4. Graphite Electrodes Technical Parameters:

Diameter: from 50mm to 600mm (2" to 24")

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- Silicon carbide graphite is very famous for its high hardness and wear resistance. It is generally used in high wear resistance machinery industry and high wear resistant sealing industry.

- Q:How should carbon deposits be treated?

- It is very necessary to clean the throttle valve, clean the nozzle, and clean the carbon in the engine cylinder! However, in order to reduce the trouble of cleaning, it is best to join the regular application of graphene Moqi additive in lubricating oil for engine.

- Q:Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- Graphite electrodes react with oxygen to form carbon dioxide, soluble in water

- Q:After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- Negative poleThe color becomes lighter (the copper ion gets electrons in the cathode and becomes copper)

- Q:Why use platinum ferroalloy instead of iron as electrode?

- General industrial grade silicon dioxide, because the preparation technology is different, can be divided into two types, one is dry, sintered (Fume Type), a wet precipitation type (Precipitated Type), and two of the surface area, the surface with hydroxyl (-OH) are the same, in general, the former the latter is more, less, the two surface has the tendency of hydrophilic, as for lipophilic polymer, such as paint, rubber... Etc.,... If the silica surface pre rendered hydrophobic, has a good effect.

- Q:What do carbon products include?

- High power electrode and ultra high power electrode. The carbon block can be divided into blast furnace carbon block, aluminum carbon block and electric furnace block. Carbon products can be divided into carbon products, graphite products, carbon fibers and graphite fibers according to the depth of processing. Carbon products can be divided into graphite products, carbon products, carbon fibers and special graphite products according to the raw materials and the production process. Carbon products according to their ash content, and can be divided into multi gray products and less ash products (including ash below l%).

- Q:Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q:What does graphite electrode GSK mean?

- Graphite is made of high-strength graphite, it is a kind of graphite grade specification.

- Q:How does graphite produce solar cells?

- In addition, the Research Report of the first author, Massachusetts Institute of Technology Department of materials science and engineering postdoctoral Zhang Shenggen said, different from other semiconductor temperature has been rising continuously, the graphite electrode coating Zinc Oxide nanowires can be temperature controlled at 175 degrees celsius.

- Q:How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Infeasible!Iron plating is not easy because two - valent iron is not well - controlled with ferric ironGenerally, metal plating with multivalent States is not well controlled

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Carbon Graphite Electrode(RP HD HP UHP) Graphite Electrode Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords