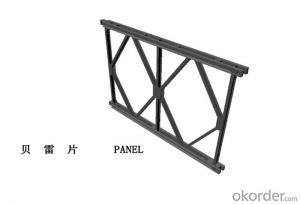

HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The compact 200 panel bridge is similar to the compact 100 panel bridge from their appearance. The difference is its increased panel height to 2.134m. It employed the method of alternating joints between Reinforcement Chords and the joints between panels. This method can decrease inelastic deformation caused by the oversized pinholes. Pre-arch method is used to additionally cut down mid-span and vertical deflection to a larger degree. Bolt-connected components use the orienting sleeve- fixing method to increase accuracy of connections. Shear is created in orienting sleeves and tension is developed in bolts, which increase the usage life of the bolts and ensure the safety of panel bridges. Wind resistant brace is made to be composite type and is connected to transom/girders to improve overall stability of panel bridges.

The part between braced frame and panels is fixed through bridging so as to prevent the whole bridge from side bending. After the erection, there will be a pre-arched degree over the span of the bridge. Besides it can be assembled into single-lane bridges. The compact 200 panel bridge can also be assembled into double lane bridge, hence it broadens its application range. It is suitable for the load designs of HS-15, HS-20, HS-25 and pedrail-50 etc.

- Q:How are steel structures used in the construction of educational and research centers?

- Steel structures are commonly used in the construction of educational and research centers due to their numerous benefits. Steel offers high strength and durability, allowing for the construction of large, open spaces without the need for excessive columns or supports. This enables the creation of versatile and flexible layouts, essential for educational and research facilities that may require frequent reconfigurations. Additionally, steel structures are fire-resistant, ensuring the safety of occupants and protecting valuable equipment. The use of steel also allows for faster construction times, reducing overall project costs. Overall, steel structures provide a reliable and efficient solution for constructing educational and research centers, meeting the specific requirements of these institutions.

- Q:How are steel structures tested for structural integrity?

- Steel structures are tested for structural integrity through a combination of non-destructive testing methods, such as visual inspections, ultrasonic testing, magnetic particle testing, and liquid penetrant testing. These techniques help identify any potential defects or weaknesses in the steel components that could compromise the overall structural stability. Additionally, load testing is conducted to simulate real-life conditions and ensure that the structure can withstand the expected loads and stresses it will be subjected to.

- Q:What are the key components of a steel structure?

- The key elements of a steel structure consist of the following: 1. Structural Members: These components serve as the primary load-bearing elements within a steel structure, including beams, columns, and trusses. Their purpose is to endure applied loads and transfer them to the foundation. 2. Connections: Connections play a vital role in a steel structure by connecting the structural members together. Common connection types comprise welded connections, bolted connections, and riveted connections. These connections guarantee the stability and integrity of the structure. 3. Foundations: Foundations are responsible for providing essential support and stability to the steel structure. Typically constructed from concrete, they are designed to distribute the structure's load to the ground, ensuring its stability. 4. Bracing: Bracing elements, such as diagonal braces and cross-bracing, enhance the lateral stability of the steel structure. They effectively resist forces like wind and earthquakes, preventing the structure from collapsing or deforming. 5. Cladding: Cladding serves as the external covering of the steel structure, shielding it from weather elements and enhancing its aesthetic appearance. Common cladding materials include metal panels, glass, and concrete. 6. Roofing System: The roofing system is a crucial component of a steel structure, providing protection against weather conditions. It encompasses roof trusses, purlins, and roofing materials like metal sheets or tiles. 7. Services Integration: Steel structures often require the integration of various services, such as electrical and plumbing systems. Proper coordination and integration of these services ensure the functionality and efficiency of the building. All of these components collaborate to create a durable, stable, and functional steel structure. Their appropriate design, fabrication, and installation are vital for the overall performance and safety of the structure.

- Q:How does the quality of steel affect the strength of a structure?

- The quality of steel directly affects the strength of a structure. Higher quality steel, which is typically made with a higher percentage of carbon and other alloying elements, has improved mechanical properties such as higher tensile strength and greater resistance to deformation. This means that structures built with higher quality steel can withstand higher loads and are less likely to fail or deform under stress. Conversely, lower quality steel may have lower strength and may be more prone to failure or structural instability. Therefore, the quality of steel is a critical factor in determining the overall strength and durability of a structure.

- Q:What is the role of steel in sustainable urban development?

- Steel plays a crucial role in sustainable urban development by providing structural strength, durability, and versatility for various construction applications. Its use in buildings and infrastructure allows for efficient use of materials, reduced energy consumption, and lower carbon emissions. Additionally, steel is highly recyclable, making it a sustainable choice that supports circular economy principles.

- Q:How are steel structures used in the construction of exhibition halls and convention centers?

- Steel structures are commonly used in the construction of exhibition halls and convention centers due to their strength, versatility, and cost-effectiveness. Steel provides the necessary support and stability required for large-scale structures, allowing for wide open spaces and flexible design options. It enables the construction of vast, column-free spaces, which are essential for accommodating large crowds and various activities such as exhibitions, conferences, and trade shows. Additionally, steel structures can be prefabricated off-site, reducing construction time and costs while ensuring high quality and precision. Overall, steel structures play a crucial role in the construction of exhibition halls and convention centers, providing a durable and efficient framework for these dynamic and multifunctional spaces.

- Q:What is the role of steel in plumbing and water supply systems?

- Steel plays a vital role in plumbing and water supply systems due to its strength, durability, and corrosion resistance. It is commonly used in various components and infrastructure such as pipes, fittings, valves, and tanks. Firstly, steel pipes are widely used in plumbing and water supply systems due to their high strength and ability to withstand high pressure and temperature. They are commonly used for transporting both cold and hot water, as well as other fluids like gas and sewage. Steel pipes are available in different sizes and thicknesses to accommodate different needs and can be easily welded or threaded to create a seamless network of supply lines. Additionally, steel fittings and valves are crucial in plumbing systems as they allow for proper control and regulation of the water flow. Fittings such as elbows, tees, and couplings are used to connect pipes at different angles and directions, enabling the creation of complex plumbing networks. Valves, on the other hand, are used to control the flow and direction of water, allowing for easy maintenance and repair of the system. Moreover, steel tanks are commonly used for storing water in both residential and commercial buildings. These tanks are designed to be robust and leak-proof, ensuring the safe storage of water for various purposes. Steel tanks can be customized to different sizes and capacities, making them suitable for different applications ranging from small residential water storage to large-scale industrial water reserves. One of the key advantages of steel in plumbing and water supply systems is its corrosion resistance. Steel pipes and tanks are often coated with protective layers such as zinc or epoxy to prevent corrosion and extend their lifespan. This is especially important in areas with harsh water conditions or high levels of chemical contaminants that may cause corrosion and degradation of other materials. In summary, the role of steel in plumbing and water supply systems is indispensable. Its strength, durability, and corrosion resistance make it an ideal choice for various components and infrastructure, ensuring the safe and efficient transportation and storage of water in both residential and commercial settings.

- Q:How are steel structures used in the construction of bars and pubs?

- Steel structures are commonly used in the construction of bars and pubs due to their numerous advantages. Steel is a strong and durable material that can support heavy loads, making it ideal for creating large open spaces and accommodating various design features. In the construction of bars and pubs, steel structures are often used for the framing and support systems. Steel beams and columns provide the necessary structural integrity to ensure the building can withstand the weight of the roof, floors, and walls. Additionally, steel is resistant to fire, which is crucial in establishments that serve alcohol and have a higher risk of accidents. The use of steel structures allows for greater flexibility in design. Steel can be molded and shaped into different forms, enabling architects and designers to create unique and appealing layouts. This versatility is particularly advantageous in bars and pubs where creating an inviting and visually appealing atmosphere is important. Another significant benefit of steel structures is their ability to span large distances without the need for intermediate support columns. This enables the creation of open floor plans, allowing for more efficient use of space and facilitating better sightlines for patrons. Furthermore, steel structures are often pre-fabricated off-site, reducing construction time and costs. This is particularly beneficial in the hospitality industry, where time is of the essence, and delays can impact revenue generation. The use of pre-fabricated steel components speeds up the construction process and minimizes disruption to the surrounding area. Steel structures also offer long-term cost savings. Steel is a low-maintenance material that does not require frequent repairs or replacements. It is resistant to pests, rot, and decay, making it an excellent choice for long-lasting and durable construction. In summary, steel structures play a vital role in the construction of bars and pubs. Their strength, durability, fire resistance, and versatility make them ideal for creating open and inviting spaces. Additionally, the use of steel structures allows for cost and time savings, making them a practical choice for the hospitality industry.

- Q:What are the design considerations for steel mezzanine floors?

- In the process of designing steel mezzanine floors, there are several important factors that need to be taken into consideration: 1. The weight-bearing capacity of the steel mezzanine floors must be able to support the equipment, machinery, or materials that will be placed on them. Therefore, it is crucial to calculate the maximum load capacity and ensure that the structural design can handle the anticipated loads without any risk of collapse or failure. 2. The design of the steel mezzanine floors must ensure structural integrity and stability. This involves considering factors such as the span of the floor, the size and spacing of the supporting columns, and the connection details between the floor and the existing building structure. Adequate bracing and reinforcement should also be incorporated to enhance the overall stability of the mezzanine. 3. It is essential to comply with local building codes and regulations when designing steel mezzanine floors. These codes typically specify requirements regarding fire safety, means of egress, access and exit points, and structural stability. Consulting with a structural engineer or an architect familiar with local regulations is important to ensure compliance. 4. Designing for accessibility and safety is crucial in order to protect workers and prevent accidents. This includes incorporating proper staircases or ladders for access, installing guardrails or handrails along open edges, and ensuring adequate lighting and ventilation. Additionally, fire protection measures, such as sprinkler systems and fire-rated materials, should be considered. 5. If the mezzanine is being incorporated into an existing building, it is important to ensure that the design seamlessly integrates with the existing infrastructure. This may involve coordinating with other trades, such as electrical and HVAC, to ensure proper placement of utilities and services. 6. Designing with future flexibility in mind is beneficial, as it allows for potential modifications or expansions. This can be achieved by allowing for adjustable connections, using modular components, and incorporating a design that can accommodate potential changes in use or layout. In summary, when designing steel mezzanine floors, it is crucial to consider load capacity, structural integrity, compliance with building codes, accessibility and safety, integration with existing infrastructure, and future flexibility. By addressing these considerations, a well-designed steel mezzanine floor can provide a safe and efficient space for various applications.

- Q:What is the difference between a steel building and a steel tower?

- A steel building and a steel tower are both structures made primarily out of steel, but they differ in their purpose, design, and functionality. A steel building is a structure that is primarily used for housing or accommodating various activities such as offices, warehouses, factories, or residential spaces. These buildings are designed to provide a controlled environment for people, equipment, or products. They typically have multiple floors, with walls and roofs made of steel. Steel buildings can be customized to incorporate windows, doors, insulation, and other features to meet specific requirements. On the other hand, a steel tower is a tall structure primarily used for communication, observation, or support purposes. These towers are designed to withstand heavy loads and provide stability in various weather conditions. Steel towers are commonly used for supporting antennas, satellite dishes, or wind turbines. They are typically built with a lattice-like framework that allows them to be lightweight yet strong. The lattice design also helps reduce wind resistance and allows for easy maintenance and access to the equipment or devices mounted on the tower. Another key difference between steel buildings and steel towers is their height. Steel buildings are generally not as tall as steel towers, which can reach significant heights depending on their intended purpose. While steel buildings are designed with multiple floors, steel towers are typically single or multi-pole structures that extend vertically. In summary, the main difference between a steel building and a steel tower lies in their purpose and design. A steel building is primarily used for housing or accommodating various activities, while a steel tower is primarily used for communication, observation, or support purposes. The design and height of these structures also vary, with steel buildings being multi-story structures and steel towers being tall, single or multi-pole structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords