steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Parameters

Item Name | steel structure workshop warehouse building |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement; (size by length/width/height and wind speed), offering a free design drawing and all detailed drawings for installation. | |

Design software: Auto CAD,PKPM,MTS,3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc | |

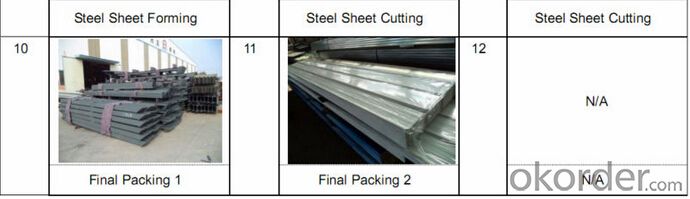

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

- Q:How are steel structures tested for structural integrity?

- Steel structures are tested for structural integrity through a combination of non-destructive testing methods, such as visual inspections, ultrasonic testing, magnetic particle testing, and liquid penetrant testing. These techniques help identify any potential defects or weaknesses in the steel components that could compromise the overall structural stability. Additionally, load testing is conducted to simulate real-life conditions and ensure that the structure can withstand the expected loads and stresses it will be subjected to.

- Q:How is the steel structure foundation checked and accepted?

- Before the steel structure is installed, the location axis, the basic axis and elevation, the bolt specifications and the location of the building shall be reviewed, and the basic inspection and handover acceptance shall be carried out. If the anchor bolt needs to check the axis and elevation of each bolt, the corresponding remedial measures must be taken when the specification is exceeded. Such as increasing the size of the column bottom, re drilling on the bottom of the column according to the actual location of the bolt.

- Q:How is the quality of steel materials ensured in construction?

- The quality of steel materials is ensured in construction through a combination of rigorous testing, strict standards, and quality control measures. Steel manufacturers follow standardized processes to ensure that the composition, strength, and durability of the steel meet the required specifications. In construction, steel materials are tested for various properties such as tensile strength, yield strength, ductility, and corrosion resistance. Additionally, third-party inspection and certification agencies are often involved to independently verify the quality of the steel. Continuous monitoring and adherence to quality control processes throughout the construction process further ensure that only high-quality steel materials are used, ultimately guaranteeing the structural integrity and safety of the building.

- Q:How do steel structures handle torsional forces?

- Steel structures handle torsional forces by utilizing various design and construction techniques. These include incorporating diagonal bracing or shear walls to resist twisting, using rigid connections such as moment-resisting frames, and ensuring the proper distribution of loads throughout the structure. Additionally, selecting appropriate member sizes and materials with high torsional resistance helps to effectively handle torsional forces in steel structures.

- Q:The exterior walls of steel buildings are colored steel plates, aren't they?

- The exterior wall is mounted with coloured steel plates.

- Q:How are steel structures designed for convention centers?

- Steel structures for convention centers are designed with careful consideration of several factors. Firstly, the design takes into account the specific requirements of the convention center, such as the size and layout of the event spaces, the number of attendees, and the types of events that will take place. The design process starts with a thorough analysis of the building's load requirements. Convention centers often host large gatherings, exhibitions, and events, so the structure must be able to withstand heavy loads. Steel, known for its strength and durability, is an ideal material for supporting these loads. Engineers use advanced software and modeling techniques to simulate and analyze the structural behavior of the steel components. This analysis helps ensure that the steel structure can handle the anticipated loads while maintaining structural integrity and safety. Another important aspect of the design process is the consideration of architectural aesthetics. Convention centers are often large and prominent buildings, so the design should be visually appealing and complement the surrounding environment. Steel structures offer flexibility in terms of shape, allowing architects to create unique and eye-catching designs. Additionally, steel structures are designed to be highly flexible and adaptable. Convention centers often need to accommodate different event configurations, such as large open spaces for exhibitions or smaller meeting rooms. Steel's inherent flexibility allows for easy reconfiguration and modifications to meet the specific needs of each event. Moreover, steel structures are known for their speed of construction. Convention centers often have tight timelines, and steel construction methods allow for faster completion compared to other materials. This can be particularly advantageous when dealing with large-scale projects like convention centers. Finally, sustainability is a crucial consideration in the design of convention centers. Steel is a recyclable material, and modern steel structures can be designed to be energy-efficient and environmentally friendly. The design may incorporate features such as natural lighting, efficient HVAC systems, and sustainable building materials to minimize the environmental impact of the convention center. In conclusion, steel structures for convention centers are designed with careful consideration of load requirements, architectural aesthetics, flexibility, construction speed, and sustainability. By combining these factors, engineers and architects can create safe, functional, and visually appealing spaces that cater to the unique needs of convention centers.

- Q:How does the design of steel structures comply with building codes and regulations?

- The design of steel structures complies with building codes and regulations by adhering to specific guidelines and standards set by local authorities. These codes and regulations ensure that steel structures are designed to withstand various loads, such as gravity, wind, and seismic forces, to ensure the safety and stability of the building. Designers and engineers must consider factors such as material strength, connection details, fire resistance, and structural integrity to meet these requirements. Additionally, regular inspections and certifications are conducted to ensure ongoing compliance with building codes throughout the construction process.

- Q:How are steel structures designed to accommodate rooftop equipment or installations?

- Steel structures are designed to accommodate rooftop equipment or installations by incorporating load-bearing capacity and structural support elements into their design. This typically involves considering the weight and dimensions of the equipment or installation, and designing the steel structure to provide sufficient strength and stability to safely support it. Additional measures such as reinforcing beams, columns, or support brackets may be included to ensure the structure can handle the added load and distribute it evenly. Ultimately, the design process aims to create a secure and stable platform for rooftop equipment or installations while maintaining the integrity of the steel structure.

- Q:How do steel structures contribute to the overall occupant comfort of a building?

- There are several ways in which steel structures enhance the overall comfort of a building. To begin with, steel's strength and durability allow for the construction of large, open spaces without the need for excessive columns or supports. This creates more flexible and open floor plans, making the building feel more spacious and free. The absence of obstructions also improves natural light distribution and ventilation, making the building more comfortable for those inside. Additionally, steel structures can withstand extreme weather conditions like high winds or earthquakes, ensuring a safer environment for occupants. This resilience not only reduces the risk of structural damage but also instills a sense of security and peace of mind. Moreover, steel has excellent thermal conductivity, which means it can efficiently transfer heat or cold. This enables the building to maintain a comfortable temperature throughout the year. Steel structures can also be designed with insulation materials to enhance energy efficiency and reduce heating or cooling costs. This effective temperature control significantly contributes to occupant comfort by providing a pleasant indoor environment. Furthermore, steel structures can easily accommodate modern technological advancements such as smart building systems and automation. These systems can control lighting, temperature, and ventilation, optimizing comfort levels for occupants. The integration of such technologies enhances the overall occupant experience and convenience. Lastly, steel structures offer the advantage of being versatile and adaptable. They can be easily modified or expanded to meet changing needs or accommodate future growth. This flexibility ensures that the building can continuously be optimized for occupant comfort, whether through layout modifications, the addition of amenities, or the incorporation of sustainable features. In conclusion, steel structures contribute to the overall comfort of a building by providing strength, durability, safety, thermal efficiency, adaptability, and the potential for integrating advanced technologies. These factors work together to create a more comfortable and enjoyable environment for the building's occupants.

- Q:How are steel structures designed to resist earthquakes?

- Steel structures are designed to resist earthquakes through several methods. Firstly, they are designed with a flexible and ductile behavior to absorb and dissipate the energy generated during an earthquake. This is achieved by using steel members that can deform without losing their strength. Secondly, steel structures are often designed with redundancy, meaning that multiple load paths are created to distribute the seismic forces throughout the structure, reducing localized stress concentrations. Additionally, connections between steel members are designed to be strong and flexible, allowing them to move and deform during an earthquake without failure. Finally, steel structures are also designed with appropriate bracing and cross-bracing systems to enhance their lateral stiffness and resistance to seismic forces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

steel structure workshop warehouse building design, manufacture and installation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords