Hardened Pipe for Truck Mounted Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hardened Pipe for Truck Mounted Concrete Pump

1. Hardened Pipe for Truck Mounted Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Hardened Pipe for Truck Mounted Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

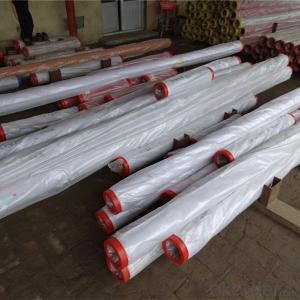

3. Hardened Pipe for Truck Mounted Concrete Pump Images:

4. Hardened Pipe for Truck Mounted Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q:What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q:How to design the power assisted robot, mechanical structure and pneumatic part, please point out, thank you!

- 1. pneumatic manipulator mechanical structure can complete the upper, lower, left, right two directions of movement and clamping, pass, to the sub bar, FA pass, looking for Witkey is too simple

- Q:What are the basic criteria for the design of mechanical parts?

- 1, first of all, to distinguish the old machine parts of the work equipment safety and health requirements(1) reasonable mechanical structure type. The intended function structure of mechanical equipment must be suitable for their implementation, not the normal operation of mechanical barrier, jammed or loose due to the unreasonable structural design; not because of the component or software defects caused by data loss or not any machine; design and mechanical equipment can be expected to not reasonable related events.

- Q:Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- There are two ways, corresponding to "bottom up" and "top down" two design methods.

- Q:What software is best for designing mechanical parts?

- The original is using autoCAD, and now popular with SOILDWORKS three-dimensional software, intuitive, easy to use, but also CAD function

- Q:What are the main principles of mechanical principles and mechanical parts design?

- 7. part surface quality requirements and corrosion protection requirements;8. cost factors;......There are many other factors.

- Q:Good mechanical design or good mechanical manufacturing?

- generally refers to some large machinery, such as CNC grinding tools and so on, need to do it yourself, go to practice;

- Q:3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- Suggest or use 3D bar, software use miscellaneous bad

- Q:In mechanical design, what is the significance of drawing 3D drawings?.

- Product design is to determine the shape of the product and product function, but also the decisionThe most important part of the product quality, the product design work on the cost of the product alsoPlay a vital role. With the continuous development of computers, CAD technology is consideredComputer aided design has become an indispensable tool for designers. CAD technology is moving from 2D CAD to 3D CAD.Three dimensional design software, engineering and productionAnalysis, calculation, geometry modeling, simulation and experiment, drawing graphics and engineering numbersAccording to library management, generate design documents and other functions. 3D CADTechnology was born toIt has been widely used in the fields of machinery, electronics, architecture, chemical engineering, aeronautics and AstronauticsAnd energy, transportation and other fields, the design efficiency of products has been improved rapidly. Our country CADTechnical research,Great progress has been made in development and popularization,Product designComplete two-dimensional CADThe popularization of technology has ended the history of hand drawing,It has played an obvious role in reducing the intensity of manual labor and improving the economic efficiency.Advantages of 3D design software2.1.1Solid modeling of parts2.1.2The product is easy to modify2.1.3Generating entity assembly drawingTwo point twomouldCAD/CAMIntegrated manufacturingTwo point threeMechanicsCAEFunction application

- Q:In the design of machine parts, how to choose the matching of bearings, what should be paid attention to when assembling?

- Bearings are purchased parts, shaft and bearing inner ring with the base hole selection, as for the flexibility of the match, depending on the use of requirements, assembly, of course, is to be installed smoothly. The bearing outer ring is matched with the box body, and the base shaft system is matched

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hardened Pipe for Truck Mounted Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords