Concrete Delivery Pipe for Putzmeister Concrete Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Delivery Pipe for Putzmeister Concrete Pipe

1. Structure of Concrete Delivery Pipe for Putzmeister Concrete Pipe:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Delivery Pipe for Putzmeister Concrete Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. Concrete Delivery Pipe for Putzmeister Concrete Pipe Images:

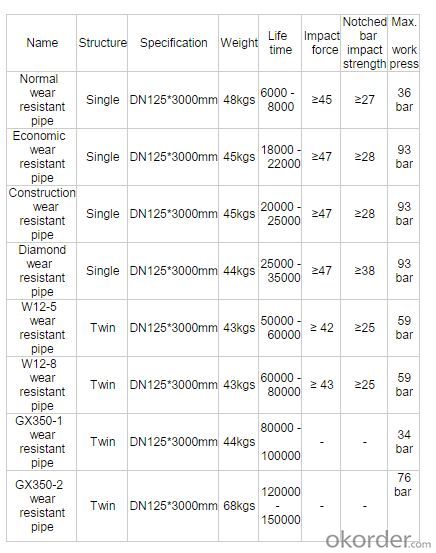

4. Concrete Delivery Pipe for Putzmeister Concrete Pipe Specification:

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:Fixture assembly drawings, detailed parts drawings, design instructions, machining processes, integrated cards, and process cards will be added

- Learn tyrants thing in the community are not practical, in the factory to consider a lot of factors, not necessarily good! Encouraging a pa! Or go to the society to study well!

- Q:The strength criterion of mechanical parts design is briefly introduced

- 1, the strength criterion requires that the working stress of the mechanical parts should not exceed allowable stress [Sigma]. The formula is typical: (3-16) lim - ultimate stress of brittle materials by static stress on the ultimate strength, the static stress of plastic materials, the yield limit of zero stress the fatigue limit. S - Safety factor. 2. stiffness criteria mechanical components are subject to elastic deformation when subjected to load. Stiffness is the ability to resist deformation of materials, mechanical parts, or structures subjected to external forces. The stiffness of the material is measured by the external force required to produce the unit deformation. The stiffness of a mechanical part depends on its modulus of elasticity, E or shear modulus, G, geometry and size, and the form of external forces. It is an important work in mechanical design to analyze the rigidity of mechanical parts. For some parts that need to be strictly deformed (such as wings, machine tools, spindles, etc.), stiffness analysis is necessary to control the deformation. We also need to control the stiffness of the parts to prevent vibration or instability. In addition, a spring, such as a spring, must be used to control its stiffness to a reasonable value to ensure its specific function. The stiffness criterion is that the elastic deformation of a component subjected to load is not greater than the allowable elastic deformation. The expression of the stiffness criterion is (3 - 17) y is an elastic deformation quantity, such as deflection, longitudinal elongation (shortening): [y] is the corresponding allowable elastic deformation. The elastic deformation of a part can be obtained by theoretical calculation or by experiment. The allowable deformation depends on the use of the part, and is determined by theoretical analysis or experience.

- Q:Machining process design of shaft parts is required

- The process is as follows:1. blanking2. drill center hole3. rough car4. heat treatment, quenching and tempering5. processing length two ends6. center hole correction

- Q:Mechanical design of various parts of the hardness value of how to determine?.

- In mechanical design, you need to determine the material, strength, and wear requirements of other parts at relatively moving locations so that you can determine how to heat the parts and achieve the best hardnessIf you are testing mature products both at home and abroad, you only need to have hardness and test materials for each part

- Q:Mechanical design practice course, let students do something

- The school is a rational knowledge, but the actual application is perceptual knowledge, the two change requires a process to know from the use, this process appears simple, it is a complex process, such as simple and fitter tools: drill and tapping, need to work in the process of careful experience that is absolutely useless empty talk, feed on illusions. No matter what other enterprises, you have to come up with real technical ability.

- Q:including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- That thing has to be paid for, no white lunch. Besides, you say that is a set of design scheme, sometimes involving intellectual property rights of enterprises / if you are the designer, the graduation design, I can tell you sorry, nobody will give you, at least I don't, those things are all mechanical design personnel spent a long time with a lot of effort to get out of the way they want to.

- Q:What is the significance of using this "three changes" in mechanical design?

- Standardization refers to the products (especially parts) the quality, specifications, performance, technical index structure and other aspects of the unified regulations and standards to perform. As the standard of our country has already formed a huge system, there are national standards, industry standards and so on. In order to in line with international standards, some standards in China the rapidly move closer to international standards. The standard code such as GB, JB, ISO and so on, they are representative of the national standard of People's Republic of China machinery industry standards, the international organization for standardization standards.

- Q:What are the basic requirements for the design of mechanical parts?

- (1) to avoid the requirement of failure in the scheduled life period1. strengthThe residual parts in the work break or do not allow the deformation of insufficient strength of subordination. The above failure forms shall be avoided for any part other than those intended for timely destruction in the safety device. Therefore, the proper strength is the basic condition that must be satisfied when designing a part.

- Q:Such as title, I am mechanical design, manufacture and automation professional, learning is mechanical design and manufacturing direction, want to PubMed, want to test automation, that is, control, and so on, not purely design and manufacture. Because I do not understand this profession, I would like to consult your predecessors and professionals, I hope you can put forward valuable opinions, under the grateful, put the rest of the pressure on ~ ~ wait for an expert to appearI qq:334175606, I hope to give advice to the professional master ~ ~ ~ also can make a friend ~ ~!

- Mechanical automation is still relatively promising, of course, if it is graduate students out, it would be better. Working on mechanical design or positioning in graduate school, undergraduate students now go out of my own experience and do not seem to make you an undergraduate student. If you're interested in an automation class, it's best because your interests can give you much motivation to study. But really want to have high demand for oneself, want to learn fine (especially in graduate student stage of study), should have own attitude.

- Q:In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- Fillet is generally cast out, chamfering is generally processed out.In order to eliminate stress concentration, a cylindrical part needs to be rounded in order to eliminate the stress concentration.In general, the outer circle, the inner hole and the threaded orifice need chamfering, some are the process requirements, some are assembly requirements (for example, you don't chamfer the parts, especially the smaller ones)...The old saying upstairs is what I want to say. I hit half and found it was called back

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Delivery Pipe for Putzmeister Concrete Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords