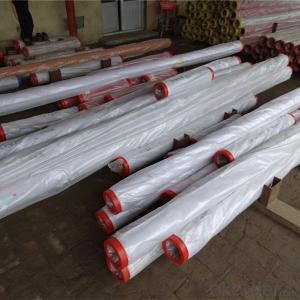

Putzmeister DN150 Concrete Pump Pipe Boom Elbow

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:What are the key factors in designing mechanical parts?

- 1- reliability. For example, the design of a transmission shaft, to consider whether the uniform load or impact load, axial load or radial load or both, or combined force. In general, even small loads can be fitted with clearance or transition fit, and tolerances can be enlarged so that processing costs are low. For high speed or large load or impact loads, interference fit should be used, such as flywheel shaft of diesel engine.

- Q:Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- There should be a lot of things. For example, the processing capacity of the equipment is only 1000mm, and the things you design have 1100mm, so the existing equipment can not be processed. For example, the surface roughness you require is Ra0.2, and the machining accuracy of your equipment can only be Ra0.8. That's more than the processing capacity of the equipment. And some things are processing problems, for example, you design things outside the small hole, there is a big hole inside, your device does not have this function.Think of these kinds of things for the time being.

- Q:is it the first overall drawing, or first out parts drawings, and then assembly?

- Take out the part drawings first and then assemble them into a whole picture

- Q:The basic idea of mechanical parts design is briefly introduced

- 1, according to the requirements and conditions, determine the type of parts2, determine the parts load, select materials, formulate parts work capacity, calculate the key size;3 、 structure design;4, drawing, marking tolerances, coordination, roughness, processing requirements and technical conditions;

- Q:including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- Design ideas for mechanical parts? Never heard of it. I've only heard of mechanical creativity.

- Q:What is the significance of using this "three changes" in mechanical design?

- Standardization refers to the products (especially parts) the quality, specifications, performance, technical index structure and other aspects of the unified regulations and standards to perform. As the standard of our country has already formed a huge system, there are national standards, industry standards and so on. In order to in line with international standards, some standards in China the rapidly move closer to international standards. The standard code such as GB, JB, ISO and so on, they are representative of the national standard of People's Republic of China machinery industry standards, the international organization for standardization standards.

- Q:What is the design procedure of mechanical parts urgently ah?!

- The technical design includes the following work: 1. kinematic design. According to the design scheme and the working parameters of the working mechanism, the dynamic parameters of the prime mover, such as power and speed, are determined, and the size and movement parameters of each component are determined. 2. dynamics calculation. According to the result of kinematic design, the load acting on the part is calculated. 3. part design. According to the load and design criterion of parts, the basic dimensions of parts are determined by means of calculation, analogy or model test. 4. overall assembly draft design. According to the basic dimensions of the components and the structure of the mechanism, the overall assembly sketch is designed. On the basis of considering the assembly, adjustment, lubrication and processing technology of parts, the structure and dimension design of all parts are completed. Determine the parts of the structure, size and parts of the relationship between the location, you can accurately calculate the role of the load on the parts, analysis of factors affecting the work capacity of parts, such as stress concentration. On this basis, the main parts should be checked and calculated, such as accurate calculation of shaft strength, life calculation of bearings. According to the result of calculation, the structure and size of parts can be modified repeatedly until the design requirements are met.

- Q:Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- The drawing code is the design code. For example, abc-00.00.01, abc-00.00.02, etc., the company should have the principle of numbering and compiling according to the drawing code in the assembly drawing.

- Q:Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- When the metal material reaches its yield limit, the plastic deformation still goes on without increasing the external force. The general mechanical parts (flanges, elbows) and engineering structural parts are not allowed to produce plastic deformation, otherwise it will fail and accidents. Therefore, the design of mechanical parts (flanges and elbows) mostly takes the yield limit as the design.

- Q:I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- Do not understand to communicate with people ah ~ you can truthfully and under the leadership of the reaction, find a master under guidance

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Putzmeister DN150 Concrete Pump Pipe Boom Elbow

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords