Concrete Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Delivery Pipe for Cifa Concrete Pump

1. Structure of Concrete Delivery Pipe for Cifa Concrete Pump:

Include four types

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Delivery Pipe for Cifa Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. Concrete Delivery Pipe for Cifa Concrete Pump Images:

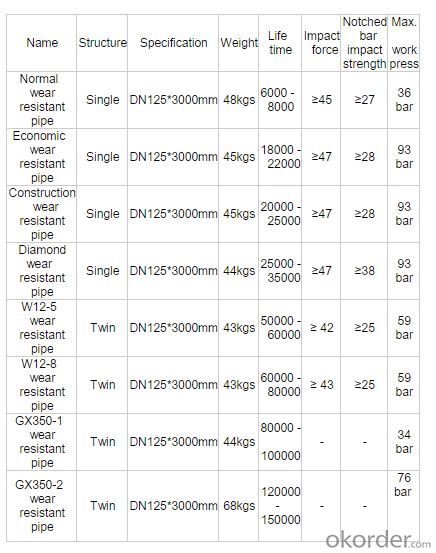

4. Concrete Delivery Pipe for Cifa Concrete Pump Specification:

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

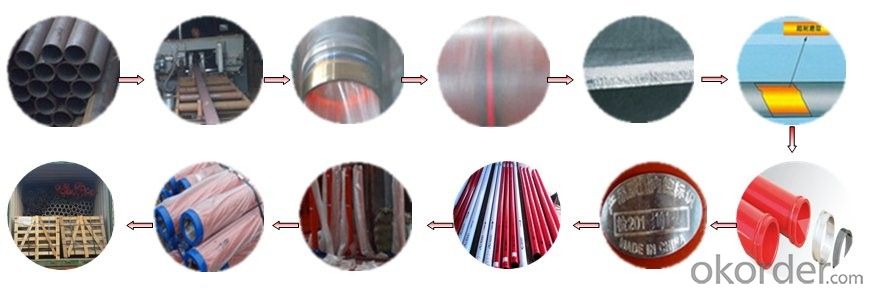

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q:What do engineers need to learn from mechanical design as an electronic hardware engineer?

- It is suggested that the first learn the "foundation" of precision machinery design, then study the "Electronic Electrical Engineering", if it is possible to learn the "modern metal material technology", because accurate small parts, put forward higher requirements on the properties of the materials used.

- Q:Are there any standards or specifications for the design of parts list in mechanical design?

- Each company's specifications are not the same, but the general processing parts must have part name, parts drawing number, quantity, material / heat treatment methods (surface treatment methods), remarks, etc.. If purchased, it includes name, model, brand, requirement, remark and so on

- Q:Machining process design of shaft parts is required

- The process is as follows:1. blanking2. drill center hole3. rough car4. heat treatment, quenching and tempering5. processing length two ends6. center hole correction

- Q:And parts, components, institutions, the relationship between the threeIs the key a part?

- The part is a processing unit, is processed. Parts of component is the moving unit. Mechanism is to achieve complete movement of the unit. For example, bicycle chain is composed of many parts (chain, pin, etc.) is a chain sprocket component;

- Q:Can the bearings used in the design of mechanical equipment be used as part drawings?

- Roller bearings do not have to draw part drawings. In assembly drawings, rolling bearings can be drawn in three different ways. These three methods are universal, descriptive and descriptive. The first two kinds are simplified drawing methods. In the same drawing, only one of these two simplified drawing methods is adopted. For the three kinds of law, the national standard "mechanical drawing representation of rolling bearings."

- Q:What is the significance of using this "three changes" in mechanical design?

- Serialization refers to the same product, under the same basic structure or basic conditions, set out a number of different size seriesGeneralization refers to the parts and components of the same structure and size, which are used in different kinds of products or different specifications of similar products"Article three" the main benefits are: to reduce the design workload, improve design quality and shorten the production cycle; reducing tool and gauge specifications, easy to design and manufacture, thereby reducing the cost; for the organization of standard parts of the scale, specialization, to ensure product quality, material saving, cost reduction; improve interchangeability, easy maintenance; macro management and regulation for the country and in foreign trade; to facilitate evaluation of the quality of products, to solve the economic disputes.

- Q:Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- I seem to have seen the online video in this class. Draw a sketch first. Forget it. I'll look for it

- Q:How does the Auto CAD menu bar do not have the "mechanical parts design" command?

- Ha, you might see someone else's AutoCAD menu bar, really, there's no original, a menu that is loaded with other plug-ins.

- Q:Good mechanical design or good mechanical manufacturing?

- The range of mechanical design and manufacturing involves relatively wide, including both mechanical manufacturing and automation;

- Q:The inside diameter of my bearing is 12mm. Now I want to work on a round shaft so that it can fit into the bearing hole, and there is almost no pulsation in the radial direction. Then how should the shaft be designed? The axle diameter is just 12mm Or a little smaller than 12mm? How much smaller?Thank you for your answer, my bearings are NSK, the accuracy level is P4, diameter 12, outer diameter 32, then how should I design the shaft? And how to design the fixed seat (sleeve, bearing) of the bearing?

- Axis of nominal diameter 10mm, size tolerance decides what you choose to look at the accuracy level of general level 6 or 7 grade precision, tolerance zone h, which is 12h6 or 12h7, the tolerance is not tight, you chose to use the occasion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords