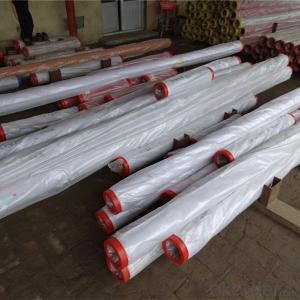

Delivery Elbow In Putzmeister Concrete Pump Truck Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- 1. design is a process of planning, planning, and imagining communicating through visual form.2., human beings transform the world through labor, create civilization, create material wealth and spiritual wealth, and the most basic and important creative activity is creation. Design is the creation of activities that are planned in advance and can be understood as the design, technology, and planning process of any creation.3., first of all, understand the user's expectations, needs, motivations, and understand the needs and limitations of the business, technology, and industry.

- Q:University contact with some simple PLC, ladder diagram, but also to understand.I University of mechanical manufacturing, graduate students made a machine tool parts, mechanical design, University contact with some simple PLC, ladder diagram, but also to understand. Now work in contact with CNC machine tools, want to learn some numerical control system, electrical knowledge, to the job after adding some capital. Online to find some 840D information, that means too hard to see, what NCU, PCU, wiring, address completely do not understand. How do I study?

- Can go to the direction of mechanical and electrical integration, good use of their own advantages. These do not understand, you can find under the internet.

- Q:Are there any standards or specifications for the design of parts list in mechanical design?

- Each company's specifications are not the same, but the general processing parts must have part name, parts drawing number, quantity, material / heat treatment methods (surface treatment methods), remarks, etc.. If purchased, it includes name, model, brand, requirement, remark and so on

- Q:Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q:An analog aircraft equipment, in the middle of the two electric cylinder to provide equipment up and down force, two electric cylinders are together and synchronized up and down movement (should be an electric cylinder support force is not enough?) I understand so, so it can only provide the upper and lower forces, the front and left of the three directions, each one of the black rod-shaped structure is how to provide the equipment about deviation, upward and downward deflection of the force? At the same time, how to make these forces achieve controllable effect, complete flight simulation?If cannot send the video address to BIRDLY Baidu flight simulator with complete video, can be seen with me after the detailed explanation, there can also be additional points I'm curious about design of the structure, the answer may take some time and I say that with QQ

- Machinery, derived from the Greek Mechine and Latin Machina, originally referred to as "ingenious design", as a general mechanical concept, can be traced back to the ancient Rome period, mainly in order to distinguish between hand tools. The word "mechanical" in modern Chinese is the generic term for "Mechanism" and "machine" (Machine). Mechanical features are: machinery is a combination of artificial physical components. A definite relative motion between the parts of a machine. So the machine can convert mechanical energy or perform useful mechanical power, is the modern mechanical principle in the basic concept, the modern concept of multi-source Chinese mechanical word from the Japanese "machinery", Japan's machinery products do the following definition of mechanical concept (that is consistent with the following three features called Machine).

- Q:Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- Agree upstairsYou write that part of your code ah, is their own parts produced by the company to write the parts of the drawing number, is the procurement of non-standard parts, the supplier to write the parts number.

- Q:Such as title, I am mechanical design, manufacture and automation professional, learning is mechanical design and manufacturing direction, want to PubMed, want to test automation, that is, control, and so on, not purely design and manufacture. Because I do not understand this profession, I would like to consult your predecessors and professionals, I hope you can put forward valuable opinions, under the grateful, put the rest of the pressure on ~ ~ wait for an expert to appearI qq:334175606, I hope to give advice to the professional master ~ ~ ~ also can make a friend ~ ~!

- I also studied mechanical design, manufacture and automation,. Generally speaking, this job covers a wide area. Depends on what direction you want to develop, mechanical and Electrical Engineering (mechanical and electrical integration), mechanical engineering, mechanical design, etc.. Today's designers are more comfortable with people who can make drawings into models, and see their own personal interests. Character.

- Q:Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- Either way, in actual work, the two approaches may alternate.If you do is mechanism design, may be other assembly references, can consider each part separately draw, so in the future by other assembly references when good maintenance, no loss of reference.If you do need to consider other parts of the related parts, such as the appearance of the skin, a variety of sports organizations, etc., can be considered to create parts in the assembly, can avoid some mistakes when combined with other parts. However, it is still recommended that you minimize the external reference in the assembly and make the key features that require external reference, and that the rest of the features are still done in an independent part manner.

- Q:I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- I really heard about this kind of company. Key: business promotion, design experience, additional experience.If you can get enough money, if you open the advertising skills and experience in mechanical design, powerful enough if you can tell the customer to design the end where I can get a good and where can I find a cheap and can ensure the processing precision and efficiency of the manufacturers, do it.On the contrary, think twice!

- Q:I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- Do not understand to communicate with people ah ~ you can truthfully and under the leadership of the reaction, find a master under guidanceA mechanical design is learning by doing, the school learned to pick it up, in addition to learn how to use the design manual, design experience for reference to others

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Delivery Elbow In Putzmeister Concrete Pump Truck Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords