Graphite Electrode With Nipple RP, HP, UHP Good Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have a complete set of graphite electrode production lines. Our products have excellent structure, good electrical conductivity and thermal conductivity, high resistance to high temperature oxidation and corrosion characteristics. Common power graphite electrode for metallurgical refining, such as electric arc furnace steelmaking plant and other applications. As China's most professional manufacturer of graphite electrode, through the ISO9001:2000 international quality system certification. We are glad to be able to quote you the most competitive price according to your request.

2.Main features of Graphite Electrodes:

1).High electrical conductivity

2).High thermal shock resistance

3).High strength

3. Graphite Electrodes Images:

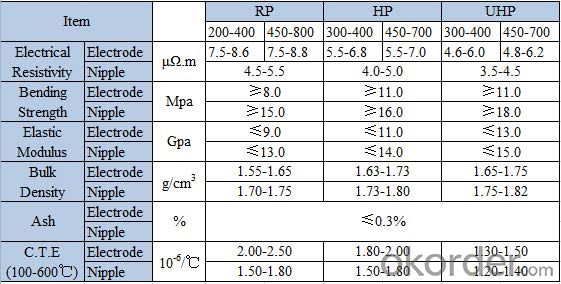

4. Graphite Electrodes Technical Parameters:

Diameter: As requirement

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

Graphite Electrodes&Company

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Instead of copper as discharge material.1. Electrode design1 can reduce the number of individual electrodes / can be made into a composite electrode2, it can save the electrode clamp system and save the cost2, the electrode processing1, high speed milling rough processing copper block 3 times2, high-speed milling finishing faster than copper 5 times3. Good machinability4, complex geometric modeling can be realized3, light weight, its density is less than 1/4 of copper1, good thermal stability (without deformation)2 can reduce the number of individual electrodes / can be made into a composite electrode3, without deburring4. The electrode is easy to clamp4 、 electric discharge machining EDM1, roughing, the electrode loss is small2, high work removal rate3 can reduce the number of individual electrodes / can be made into a composite electrode4. No pollution to the environment in the electrolyte5, light weight, its density is less than 1/4 of copper6, excellent thermal stability, the electrode does not change7, the fine graphite electrode can be used to produce high quality workpiece surfaceDifferent grades of graphite materials can be used for processing different workpieces

- Q:Is graphite electrode good for foreign trade?

- Foreign sales commission depends on the price you talk to the customer, and the profit is objective.

- Q:What kind of asphalt is better for natural graphite coating?

- Special graphite mainly to high quality petroleum coke as raw material, coal tar or synthetic resin as binder, the raw material preparation, mixing, kneading, pressing, crushing, mixing, molding, roasting, soaking, repeatedly repeated purification and graphitization, and made the processing machine. It is generally used in the aerospace, electronics and nuclear industry sectors. It includes pure graphite, high purity, high strength, high density and pyrolytic graphite.

- Q:How can the graphite powder be processed into high quality carburizing agent? Thank you

- So that impurities on the high, so basically can not be processed into so-called quality, and can leave a contact, discuss each other

- Q:Graphite electrode specifications, graphite electrode manufacturers which good?

- The key is you use and what type of need, say, abroad, what Dongyang, sigley are good, but also, very expensive, you can also choose to try our home

- Q:Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q:What is the composition of petroleum coke and what is its use?

- Petroleum coke can be used for the manufacture of graphite, smelting and chemical industries, depending on its quality. For example, the quality of cooked sweet coke coke, mainly used in the manufacture of ultra high power graphite electrode and some special carbon products; needle coke in steelmaking industry is an important material new technology development of EAF steelmaking.

- Q:What is the difference between SGL graphite electrode and graphite electrode in general?

- Pure graphite is a kind of high-purity graphite. The processing technology of fine graphite and high purity graphite is basically the same, that is, the purity of graphite is different, the purity is higher, and the particle size is basically the same

- Q:What are the factors affecting the service life of graphite electrode in ultra high power arc furnace?

- China's graphite electrode quality standard (YB/T4090-2000) to evaluate the quality of the ultra high power graphite electrode is defined 6 physicochemical indexes, including resistivity, flexural strength, elastic modulus, bulk density and linear expansion coefficient as the quality evaluation index, ash as a reference index.

- Q:In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For the mold finishing, most of the time are red copper click, low loss, high precision, of course, higher precision, or requirements of copper tungsten alloy electrodes are also available

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode With Nipple RP, HP, UHP Good Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords