Good Quality Ferro-Manganese for Sale Chinese Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Ferro-Manganese for Sale Chinese Supplier

Usage of Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

Introduction:

It used the high quality anthracite as raw materials through high temperature calcined at over 2000 by the DC electric calciner with results in eliminating the moisture and volatile matter from anthracite efficiently, improving the density and the electric conductivity and strengthening the mechanical strength and anti-oxidation. It has good characteristics with low ash, low resistvity, low sulphur, high carbon and high density. It is the best material for high quality carbon products.

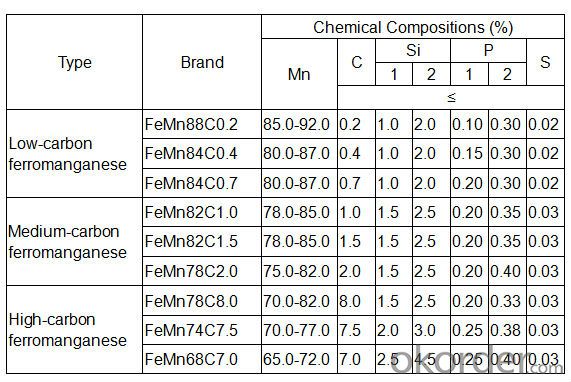

Specification of Ferro manganese

The specification and size can be made as your demand.

PICTURES:

- Q:One can write on the hard alloy on the pencil, what's the name ah, who knows.

- You need it. It's all there. You're over there

- Q:The use of cemented carbides YG and YT

- Three, need to point out is: YG, YT, YW each alloy has different models, each model has different applicable range, the above refers to the comprehensive analysis.

- Q:HSS clip can clamp the hard alloy saw it

- A straight back; often used in fine toothed finishing mills. Both the curve and the back teeth have good strength and can bear heavy cutting load. They are often used in coarse tooth mills.Relieving cutterThe back is made by the method of shovel (or grinding), which is machined into the back of the spiral of Archimedes. The cutter only needs to be regrinding before it is blunt, and the original tooth shape can be kept unchanged. It is used to make all kinds of formed milling cutters such as gears and milling cutters.

- Q:Which is better, cemented carbide, YG8 and YG20?

- YG8 contains about 8% cobalt, the hardness is higher than YG20, and the strength is lower than YG20,

- Q:I would like to use carbide cutting tools, car work, ordinary A3 steel or 45 steel, lathe speed to play more appropriate, the workpiece surface quality is better?

- LZ, I don't know if you did it for eight years or eight years. When you finish the car hit 1600 turn, your knife is a diamond? I'll ask you to open 6 is the number of mid-range lathe wire ah, the general lathe open open 6 mid-range at least twenty-six wire, when you finish turning with so high feed! Even if you use 1600 rpm and this knife, your surface is bright, but your workpiece roughness must be unqualified. Remember, finish is not roughness. You are good at the question. The cutting speed is based on what kind of cutting depth and amount of knife you choose when you rough the car. You don't say the exact size of the part you want to process. That's not good. The key experience is to rely on their own step by step, tired.

- Q:What are the standard units of measurement for carbide inserts?

- Manufacturers usually use KG, which is used inside the shop

- Q:Carbide cutting insert

- These brand knives are usually Zhuzhou diamond brand and Zigong the Great Wall brand. Other brands are also located in these areas.

- Q:After welding, and then sharpening, grinding into 4 Pyramid shape, and then used to knock stone, which is not easy to bad, which is more durable? Model number is D224, I would like to ask you, which should I buy? I'm mainly used for knocking stones.

- YG8C is used on impact drills, which is suitable?

- Q:What type of emery grinding machine is 3000/min for grinding carbide turning tools (e.g., YG8.YS8.YT15.YW1, etc.)?

- Diamond grinding wheel, green carborundum wheel can be used. Two, choose one, or choose the former good. Diamond grinding wheel has the advantages of less wear, long life, high productivity and good processing quality, that is, the price is a little more expensive.Grinding wheel: grinding wheel is also called consolidation grinding tool. It is a kind of consolidation grinding tool, which is bonded by the bond agent into a certain shape (most round, central through hole) and has a certain strength. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc.. The characteristics of grinding wheel are mainly determined by abrasive, particle size, bond, hardness, microstructure, shape and size.

- Q:What are hard alloys? Which ones are they? How often are they chosen?

- It is based on one or several carbides (TiC and WC) as the hardening phase, with carbon steel or alloy steel (such as high-speed steel, chrome molybdenum steel) powder as binder, powder metallurgy materials through proportioning, mixing, pressing and sintering. After annealing, it can be machined. After quenching and tempering, it has the same hardness and high wear resistance as the hard alloy. It can also be forged and welded, and has the characteristics of heat resistance, corrosion resistance and oxidation resistance. The utility model is suitable for manufacturing various tools with complicated shapes, such as twist drills, milling cutters, etc., and can also manufacture moulds and wear-resistant parts which work at higher temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Quality Ferro-Manganese for Sale Chinese Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products