Medium Carbon -Ferro-Manganese C2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

The specification and size can be made as your demand.

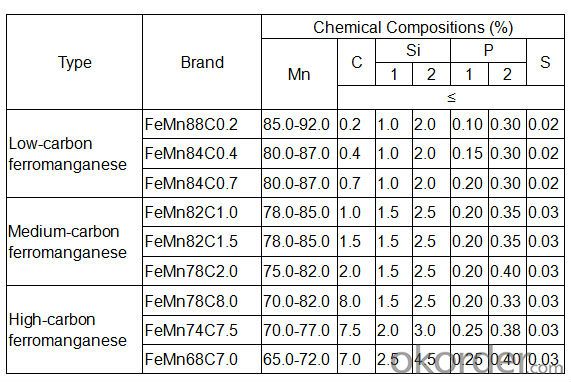

PICTURE

- Q:In addition, the same furnace products out, the standard sample bar is qualified, no hole, but YT14 blade has more holes, why is that ah?

- YT14 Feiyan containing titanium, titanium with high oxygen affinity, if high oxygen content and sintering process not reasonable, high temperature gas production could not be drained to form holes, you see the sintering process is reasonable, the presence of liquid phase before the vacuum degree is not high enough. In addition, such as incomplete degassing holes in the product, the edge is more.

- Q:What materials are ZK20 cemented carbides processed?

- ZK20 belongs to the K hard alloy blades can car many materials, such as: wrought iron steel low alloy cast iron high alloy cast iron ductile cast iron Aluminum Alloy hard plastic

- Q:Why carbide fracture?

- First you have to choose the right material. Various uses must choose the relative grade, and also has the material which you use, has the sundry inside

- Q:What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- The former is cut by ordinary metal materials, the latter is used for cutting superhard materials

- Q:Carbide yk20? What do you mean?

- Cemented carbides YK20, Y represent alloy categories - tungsten cobalt, K20 represents cobalt contentDensity g/cm3:14.30-14.60;The hardness of HRA is more than or equal to 86.5;The shear strength is greater than or equal to N/mm2:2350,Performance and usage: with high toughness and wear resistance, suitable for embedding percussive rotary drilling bit, drilling in hard and tight hard rock.

- Q:What is the specific gravity of cemented carbide?

- Similar to mercury. Tungsten cobalt carbide 14.4~15.3 density, tungsten, cobalt, titanium carbide 9.7~13.2 density, can float in the mercury is a steel knife, sink into the mercury is a cast iron knife

- Q:Can hard alloy be made into barrel?

- No, hard alloy too hard too fragile, not processed, there should be a rifle barrel, it is difficult to machining.

- Q:Carbide saw blades, plain and alternating teeth. What do you mean? That good?

- .1., about the most widely used teeth, cutting speed, grinding relatively simple. Suitable for cutting and crosscut various soft and hard wood materials and MDF, plywood, particleboard etc.. Equipped with anti elastic protection around the tooth is tooth plate for dovetail, longitudinal cutting of various degree; with negative rake angle of tooth saw blade sharp, serrated cutting because of good quality, usually used for veneer cutting.2. flat tooth saw is rough, cutting speed is slow, grinding is the most simple. Mainly used for sawing ordinary wood, the cost is lower, more used for smaller diameter aluminum saw blade, in order to maintain cutting to reduce adhesion, or used for grooving saw blade, to keep the groove bottom leveling.

- Q:Dalian enterprises now need 16.3 and 19.3 mm in diameter, the whole cold hard alloy bit, where can I find buyers? Leave a contact

- I know Zhuzhou Hua tungsten seems to have what you need. I suggest you go to see their company

- Q:Japan steel tungsten carbide which is good

- Japan steel tungsten carbide recommended Kunshan aloi precision mould Co. Ltd, Japan Istanbul technology research of copper tungsten alloy used for professional sales of Japanese steel tungsten carbide and discharge EDM, silver tungsten alloy, copper alloy; discharge EDM tungsten copper, copper thread electrode; non-standard thread electrode, thread grinding machining

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Medium Carbon -Ferro-Manganese C2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords