GExtruded Graphite Rod/HPraphite Electrode/Synthetic Graphite Rod Blank Dia 90mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

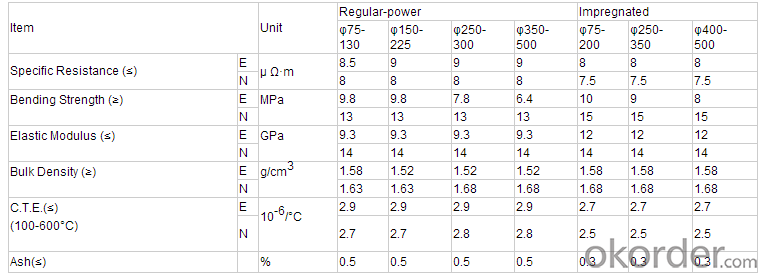

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- But because the silicon carbide is too hard, it is difficult to machining, good workability, such as non special requirements, using graphite instead of silicon carbide, instead of the effect is not good, but can use a silicon carbide, easy processing, small life than silicon carbide.

- Q:Synthesis techniques of carbon nanotubes

- Catalytic pyrolysis is one of the widely used methods for preparing carbon nanotubes. The method mainly uses transition metal as catalyst, and is suitable for large-scale preparation of carbon nanotubes. The content of carbon nanotubes in the products is higher, but the defects of carbon nanotubes are more.

- Q:What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The hardfacing of wear-resistant alloy powder block is mostly made by carbon arc surfacing. General selection of graphite or carbon arc surfacing carbon rod and plate electrodes, which has good conductivity, high melting point;

- Q:MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q:What is the difference between pyridine type nitrogen and graphite type nitrogen?

- In fact, this problem is very simple, the carbon graphite is six square lattice ordered, natural graphite and artificial graphite is divided into two kinds: the classification of natural graphite flake graphite and graphite is earthy, basically it is not forming soil shaped graphite graphite, are rough machining, the battery core and do more. The use ratio of flake graphite.

- Q:Why should supercapacitors use graphite as electrode material?

- Because graphite material processing speed is fast, the cost is low.

- Q:How about graphite electrode high-temperature oxidation resistant coating?

- The utilization ratio of graphite energy can reach more than 95%. Many kinds of antioxidant paint, it is recommended to directly find their technicians, you can give professional advice, according to the actual situation, the reasonable use of high-temperature oxidation resistant paint.

- Q:Electrolysis of CuCl2 solutions with graphite electrodes

- The energization is the electrolysis of CuCl2 solutions, i.e., redox reactions. So you can't mix ionization and electrolysis.

- Q:Electrolytic salt water why use iron as a cathode, all with graphite can not?

- When electrolyzed salt water is used, the cations in the solution (H+, ionized by H2O) are moved to the cathode by the electric field force, and electrons are generated at the cathode to produce H2 hydrogen, and the hydrogen H2 generated does not react with iron

- Q:Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GExtruded Graphite Rod/HPraphite Electrode/Synthetic Graphite Rod Blank Dia 90mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords