fine and high purity calcined alumina powder al2o3 for ceramic,refractory,glaze,Metallurgy

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fine and high purity calcined alumina powder with 99.5% al2o3 for ceramic,refractory,glaze,Metallurgy

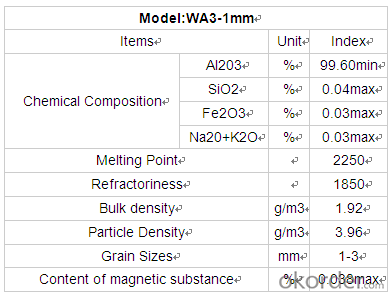

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application of AL2O3

*Wear resistant ceramic, electronic ceramics, small ceramic parts.

*Refractory- - Shaped refractory (firebrick etc) & Unshaped refractory (castable etc)

*glaze series.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:How is the fire endurance of the fireproof paint?

- This is not specified. It depends on design requirements.The products we made have fireproof endurance ranging from 1 to 4 hours. we have not done any higher.

- Q:How to do environmental impact assessment for refractory Co., Ltd.

- The preparation of a report or statement. During the compilation process, any problems should be actively communicated with the construction side. For example, dust collector selection, environmental protection investment, total emission approval. (especially the total emission, you must let the construction side and communicate with the environmental protection bureau to get the total amount, otherwise you write the EIA does not make any sense.) Generally speaking, the preparation of the report is longer, about forty days; and the preparation of the report table is shorter, about fifteen days.

- Q:What can red stone refractory do?

- In severe cases, the resistance to high temperature without softening down the Celsius temperature. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output. Chinese use less impurity clay in more than 4000 years ago, firing pottery, and have been able to cast bronze. In the Eastern Han Dynasty (AD 25 ~ 220) have been used to make clay refractory kiln firing porcelain material and sagger. At the beginning of twentieth Century, the development of refractories to high purity, high density and ultra high temperature products, while developing completely without firing, small consumption of unshaped refractory materials and high refractory fiber (160 for industrial furnace refractories above 0 DEG C). The former, such as alumina refractory concrete, is often used in large chemical plants, ammonia synthesis plant, two - stage reformer furnace wall, the effect is good. Since 50s, the rapid development of atomic energy and space technology, the development of new energy technology, requires the use of special refractory material of high temperature resistance, corrosion resistance, thermal shock resistance, erosion has excellent properties, such as melting point above 2000 DEG C, oxide refractory compounds and high temperature composite refractory materials.

- Q:What is the upper temperature limit for refractory materials?

- The key depends on what refractories you use

- Q:What is acid refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions. Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used. Neutral refractory is mainly composed of alumina, chromium oxide or carbon.

- Q:What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- Alkali resistant castables cost the least.

- Q:What are the structural properties of refractory materials provided by the manufacturer of the refractories include?

- On the other hand, the turbulence is severe, and the side wall of the tundish is washed into the liquid steel and the service life of the lining of the tundish is reduced. In order to solve this problem, China 5%% honing develops a tundish anti turbulence pad, which is made of Al2O3>75% high alumina castable. Anti turbulence pad mounted casting ladle and tundish flow impact zone in the bottom of the flow out of the steel ladle nozzle casting hole center back in the anti turbulence pad repeatedly to consume the kinetic energy of the fluid flow, thereby reducing the steel flow speed, avoiding turbulence.

- Q:What is the difference between wear-resistant material and refractory material?

- However, the purity and the requirement are not the same. For example, brown emery is often used in abrasive paper, which doesn't matter. Refractory material uses brown corundum brick. The material used in texture and refractory material of abrasive is different. For example, it is to facilitate their forming and easy sintering. However, some other materials should be added when making brown corundum brick. In general, some top grade materials are used to make abrasive.

- Q:What is the particle size of boron carbide for refractories?

- 2 floor is right, support, learning! But what do you mean by boron carbide (d90=36.5, m)?

- Q:who knows the fire endurance of fireproof coating?

- this is not specfied , depending on design requirements. The products we made have fire endurance from 1to 4hours . We have not done any higher.how is the fireproof coating in improving fire resistance of building components? finishing fireproof coating; wood fireproof coating; fire-resistant coating for steel structure, fire-resistant coating for concrete structures, tunnel fire retardant paint, fire retardant paint for the cable. Fire retardant coating is composed of the base materials (that is film forming substance), pigments, ordinary coating additives, fire retardant agent and dispersion medium. In addition to fire retardant agent, other components functions the same as in ordinary coating, but its performance and thickness are specifically required.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

fine and high purity calcined alumina powder al2o3 for ceramic,refractory,glaze,Metallurgy

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords