All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

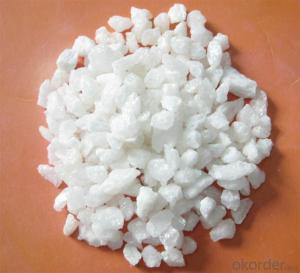

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How are refractory plastics prepared?

Refractory plastics are prepared by mixing refractory materials, such as alumina or silica, with a binder and other additives to form a plastic-like consistency. The mixture is then shaped or molded into the desired form before being cured or fired at high temperatures to achieve the desired refractory properties.

What are the common types of refractory coatings for chemical corrosion resistance?

The common types of refractory coatings for chemical corrosion resistance include ceramic coatings, epoxy coatings, polyurethane coatings, and rubber coatings.

What is the role of refractory materials in furnaces?

Refractory materials play a crucial role in furnaces by providing insulation and protection against high temperatures, chemical reactions, and mechanical stress. They help to maintain the desired temperature inside the furnace, prevent heat loss, and ensure efficient combustion. Moreover, refractory materials can resist corrosion from molten metals or harsh chemicals, extending the lifespan of the furnace. Overall, they are essential for the effective and safe operation of furnaces in various industries such as steel, glass, cement, and ceramics.

Wholesale Refractory Materials from supplier in Iran

Our team of experts is dedicated to providing top-quality refractory materials for various industries, including steel, cement, glass, and petrochemicals. We understand the importance of reliable and durable materials in these sectors, which is why we only source products from trusted manufacturers.

In addition to supplying refractory materials, we also offer sales and quotation services. Our dedicated sales team will work closely with you to understand your requirements and provide competitive pricing options. We believe in building long-term relationships with our clients and strive to exceed their expectations.

Furthermore, our technical support services are designed to assist you throughout your project. Our experienced engineers can provide guidance on material selection, installation techniques, and troubleshooting. We aim to ensure that your project runs smoothly and efficiently, avoiding any potential delays or issues.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to provide all-in-one procurement solutions, ensuring that you have everything you need for your refractory materials in Iran.

We take pride in our extensive product portfolio, which includes a wide range of refractory bricks, castables, mortars, and insulation materials. Our team continuously monitors the market to stay updated with the latest advancements and industry trends, allowing us to offer innovative and high-performance solutions.

Overall, we are committed to contributing to the success of your projects by providing top-quality refractory materials, excellent sales and quotation services, and reliable technical support. Contact us today to discuss your requirements and let us be your trusted partner in Iran.

In addition to supplying refractory materials, we also offer sales and quotation services. Our dedicated sales team will work closely with you to understand your requirements and provide competitive pricing options. We believe in building long-term relationships with our clients and strive to exceed their expectations.

Furthermore, our technical support services are designed to assist you throughout your project. Our experienced engineers can provide guidance on material selection, installation techniques, and troubleshooting. We aim to ensure that your project runs smoothly and efficiently, avoiding any potential delays or issues.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to provide all-in-one procurement solutions, ensuring that you have everything you need for your refractory materials in Iran.

We take pride in our extensive product portfolio, which includes a wide range of refractory bricks, castables, mortars, and insulation materials. Our team continuously monitors the market to stay updated with the latest advancements and industry trends, allowing us to offer innovative and high-performance solutions.

Overall, we are committed to contributing to the success of your projects by providing top-quality refractory materials, excellent sales and quotation services, and reliable technical support. Contact us today to discuss your requirements and let us be your trusted partner in Iran.

Hot Search

- Monolithic Refractories in British

- Ceramic Fiber Products in Botswana

- Refractory Bricks in Honduras

- Raw Materials For Refractory in Sweden

- Refractory Bricks in Algeria

- Monolithic Refractories in Kazakhstan

- Ceramic Fiber Products in Estonia

- Monolithic Refractories in Sudan

- Refractory Bricks in Tonga

- Raw Materials For Refractory in Japan