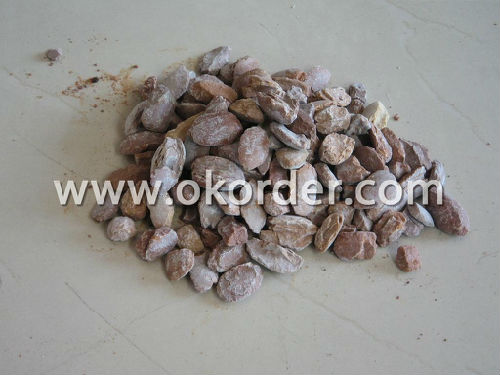

Dead Burnt Magnesite

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Dead Burnt Magnesite:

Dead Burnt Magnesite is selected from natural magnesite, calcined temperature and the shaft kiln. It is the material of ordinary magnesia bricks, shaped and unshaped refractory products.

Specifications of Dead Burnt Magnesite:

Specification(%) | ||||||

Brand | MgO min. | LOI max. | SiO2 max. | CaO max. | Fe2O3+Al2O3 max. | B.D.G/cm3 min. |

DBM90 | 90.00 | 1.00 | 4.50 | 2.50 | 3.00 | 3.1 |

DBM-95 | 95.00 | 0.30 | 3.00 | 2.00 | 1.30 | 3.15 |

DBM-97 | 97.00 | 0.20 | 0.7 | 1.3 | 0.90 | 3.25 |

DBM-972 | 97.2 | 0.2 | 0.6 | 1.3 | 0.9 | 3.27 |

DBM975 | 97.5 | 0.1 | 0.6 | 1.2 | 0.8 | 3.28 |

Applications of Dead Burnt Magnesite:

Mainly used in processing raw materials of different particle size to create a variety of magnesia refractory,

more used openhearth furnace for the production of steel lining the bottom and ramming mixes;

manufacturing the raw materials of magnesia brick and magnesiachrome brick ;

used electric steelmaking furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages:

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q:What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q:Can anyone tell me the requirements of the refractory masonry??

- Kaolin is mainly composed of kaolinite crowded minerals that is in the shpe of tiny flake which is less than two microns, tube and folding flake. The kaolinite crowded mineral consists of kaolinite, dickite, pearl stone, halloysite, etc. and its ideal chemical formula is AL2O3-2SiO2-2H2O. The main mineral component of it is kaolinite and halloysite.In addition to the kaolinite crowded mineral, kaolin is accompanied by other minerals like montmorillonite, illite, pyrophyllite, quartz and feldspar. The chemical composition of kaolin contains large amounts of AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and traces of K2O, Na2O, CaO and MgO, etc. The white pottery is made of kaolin. At present, the internationally accepted scientific name for kaolin is Kaolin which is derived from the kaolin mountain in the eastern suburb of kaolin village in Jingdezhen.Such special properties of kaolin as its plasticity,cohesiveness, certain dry strength, sinterability and firing whiteness make it the main raw material for ceramic production; properties like whiteness, softness, high dispersibility, and adsorbability allows it to be widely used the paper industry. In addition, the kaolin is also widely used in some industrial sectors such as rubber, plastics, refractories, oil refining as well as agriculture sector and cutting-edge technology for national defense. According to the purpose and requirements, kaolin can be processed and purified and it can be used to manufacture activated clay.

- Q:What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q:What do refractory materials include?

- It is so difficult.

- Q:What kind of refractory material should be used for common boiler?

- Build by using clay refractory mortar. Common clay brick is used as combustion layer. Xindeyuan Refractory Material, red?brick is used as external wall. Light clay brick is used as thermal insulation layer, thank you.

- Q:Who knows the external wall thermal insulation materials fire rating requirements?

- The basic requirements of ratings. The design should comply with relevant state regulations and standards, the combustion performance used in exterior insulation material shouls be level A and not less than the level B2 fireproofing material. The requirements of Department of Housing and the Ministry of Public Security No. 46: Residential buildings: the height of building is greater than 100 meters, the combustion performance of insulation materials should be level A. The other civil buildings: 24≤ height

- Q:What is the main material of fireproof wooden door?

- Fireproof wooden door has a lot of materials! including imported timber decorative effects: utilizing the diversity and easiness to cut of the timber, with all the decorative characteristics of the timber. Material selection features, door frames: Using high-quality hardwood, such as imported miscellaneous wood, camphorwood, lauan, hemlock, etc., insetting fire and smoke proof adhesive tape

- Q:Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- Add some hair and slags, or it will crack before calcination.

- Q:Does anyone know the fire endurance of steel stud partition?

- Indeed ① Dragon Brand gypsum board fire-resistant partition: Its fireproofing extreme time is 4 hours, suitable for firewalls of a variety of public buildings, public exit passageway and other partitions, which meets the first level of fire protection standard ② fireproofing and pressure-resistant partition: Refers to the partition which can withstand momentary gas shocks of over 1200pa , mianly used for the room partition with inert gas fire-fighting needs, such as equipment rooms. The pressure-resistant degree of fireproofing and pressure-resistant partition of Beixin Building Materials can be up to 4800Pa, especially suitable for high-rise fireproofing.

- Q:who knows the uses of refratories?

- Of course, the role of the refractory material is fireproof, generally used in large buildings. It can reduce casualties and economic losses caused by the fire. it also can be used on the chemical instruments. ! !

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Dead Burnt Magnesite

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords