Fiberglass Mesh Roll Reinforcement 100gram

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Roll 100gram Reinforcement

Fiberglass Mesh Roll 100gram Reinforcement is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

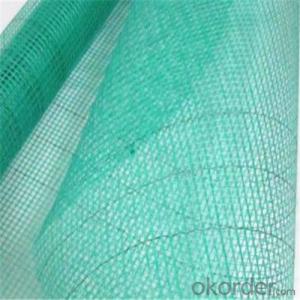

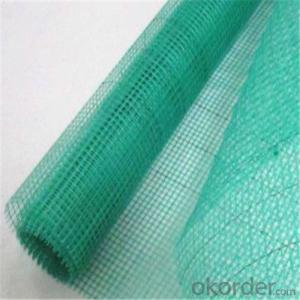

Image of Fiberglass Mesh Roll 100gram Reinforcement

Quick Detail of Fiberglass Mesh Roll 100gram Reinforcement

FOB Price of Fiberglass Mesh Roll 100gram Reinforcement: US $0.21 – 0.32 / Square Meter

MOQ of Fiberglass Mesh Roll 100gram Reinforcement: 5000 Square Meters

Supply Ability of Fiberglass Mesh Roll 100gram Reinforcement: 2000000 Square Meters per Month

Loading Port of Fiberglass Mesh Roll 100gram Reinforcement: CHINA MAIN PORT

Payment Terms of Fiberglass Mesh Roll 100gram Reinforcement: L/C, T/T

Specifications of Fiberglass Mesh Roll 100gram Reinforcement

Fiberglass Mesh Roll 100gram Reinforcement Place of Origin: China (Mainland)

Fiberglass Mesh Roll 100gram Reinforcement Brand Name: CMAX

Fiberglass Mesh Roll 100gram Reinforcement Application: Wall Material, Marble Slab Reinforcement

Fiberglass Mesh Roll 100gram Reinforcement Width: 1M-2M

Fiberglass Mesh Roll 100gram Reinforcement Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Fiberglass Mesh Roll 100gram Reinforcement Weight: 40gsm to 200gsm

Fiberglass Mesh Roll 100gram Reinforcement Length/ roll: 50m-100m, Special spec can be customized

Fiberglass Mesh Roll 100gram Reinforcement Weave Type: Leno, Plain Woven

Fiberglass Mesh Roll 100gram Reinforcement Yarn Type: C-Glass, E-Glass

Fiberglass Mesh Roll 100gram Reinforcement Alkali Content: Medium Alkali

Fiberglass Mesh Roll 100gram Reinforcement Standing Temperature: 500℃

Packing and Delivery of Fiberglass Mesh Roll 100gram Reinforcement

Package: Each Fiberglass Mesh Roll 100gram Reinforcement roll is wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order of Fiberglass Mesh Roll 100gram Reinforcement

Application/Usage of Fiberglass Mesh Roll 100gram Reinforcement

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Roll 100gram Reinforcement

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Roll 100gram Reinforcement?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Roll 100gram Reinforcement?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Roll 100gram Reinforcement?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Roll 100gram Reinforcement?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q:Each unit project of alkali resistant gridding cloth should send several groups for inspection.

- The inspection length should be less than 3 if the material is used in 20000 ㎡ public buildings, residential, commercial buildings with the same construction, same production manufacturer and same process construction and less than 6 if the area is more than 20000 ㎡.

- Q:What's the difference between window screens and window screens?

- Screen window is made of chemical fiber as raw material. It's a very thin cloth. Usually with curtain cloth matching. A cloth. Ply yarn. A gauze screen that sticks over a door and window to become a window screen; a screen is widely used in doors and windows and corridors to prevent small insects from disturbing the net. Mostly made of nylon, common white, green and blue. Sometimes also called screen window. The main role is "anti mosquito screen window". Now the screen window is more than before, more patterns, invisible screen window and removable screen window, no longer as hard as before the window will be removed and removed.

- Q:The household is screened glass fiber gauze or stainless steel gauze.

- Of course, the glass fiber network is good, the warp and weft bonding. Yarn mesh size is constant, suitable for cleaning,

- Q:Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Rock wool with two layers of mesh cloth and not improve crack resistance, but because wool soft texture, installing the anchor bolt after the surface is uneven, with two layers of mesh is to increase the thickness of the mortar, to find the plane. There is no such phenomenon in the extrusion board.

- Q:Why is it required to be under 5℃ while paving carbon fiber mesh?

- Hang horizontal line in suitable palces on each floor. Specially-assigned person is responsible for compounding special adhesive. Fastener installation should be held at least 24 hours later, finishing pasting board. The length of the fixed plate is 50mm-thickness. Plastering polymer mortar and binding agent should be instant. 5mm-1mm surface layer of mortar, depending on the fixture aperture diameter, depending on the plate surface polished, non-standard size or a continuation is at field-crop, internal and external corners must be lapped ony by one to strengthen the role of the defense, playing the line of control. Because of its excellent acid resistance, it won't crack though subjected to all sorts of changes in stress without cracking, since the glass fiber mesh obedient.

- Q:What purposes do dry-type transformers epoxy resin mesh have ?

- 1, the product adopts high quality, wax-free, E-glass and electric fiber yarn as the substrate, knitted into a variety of mesh cloth, and is made through heat drying dehydration, and then impregnated with epoxy resin mixture unique formula, dispensing glue under moderate temperature, and heat drying curing. 2, according to the property of the impregnated resin, the products can be divided into solvent and solvent-free mesh mesh. The main differences between the two mesh are as follows: 2.1, impregnated resin is different: Solvent Mesh contains acetone, solvent-free mesh is pure resin. 2.2, different procedures of impregnation: Solvent mesh is impregnated at normal temperature air, and it is opaque; while solvent-free mesh is impregnated under the medium-temperature vacuum pressure, and the mesh is transparent. 2.3, containing different amounts of plastic: The proportion of resin contained in solvent-free mesh is much larger than a solvent mesh, about twice of the solvent mesh. 2.4 application is different: Solvent-free mesh is suitable as an insulating layer between the coils with no partial discharge at very high field intensity the use of solvent-free mesh can reduce the thickness of the interlayer insulation.

- Q:What are the types of mesh?

- 1000mm Length: 600mm: White (standard). Mesh Size: 50m: Interior wall insulation fiberglass mesh: According to customers' requirements

- Q:Mesh and fiberglass cloth, which is better?

- Fiberglass cloth is better with high cost.

- Q:Can glass fiber gridding cloth waste be recycled? If can, then what is is?

- The acrylic in grid cloth can produce pungent smell and cause serious soil pollution after high temperature, which proves the environmental protection of glass fiber. It may cause serious air and soil pollution and contain harmful substance to respiratory system. And the core material of grid ding cloth is flame retardant and cannot be burnt.

- Q:In what circumstances do you need to paste the mesh, if not, it is okay?

- Of course, pasting the whole wall is the best, but the mesh is usually used for cracking at the joint, the whole crack?resistance of dacron cloth is better, but it will increase the budget of $ 5-8. If it is a new house, decoration has better to do patch treatment; if it is second?decoration, the walls are relatively intact, it is not necessary to paste.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mesh Roll Reinforcement 100gram

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords