Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

fiber cement board

-Factory price

-SGS,CE

-Non-asbestos, light weight, high density

-Waterproof, fireresistant, anti-bendingfiber cement board panels sheet for exterior cladding wall construction building material

2,Main Features of the (Cement Boards)

Fire-proof Rate: Class-A incombustible GB8624-1997

Incombustibility (min):240 minutes(GB/T9978-1999)

Density:1100~1500g/cm3

Water content ratio: ≤30%

Swelling ratio:≤0.4%

Anti-bending strength:≥16MPa

Frost Resistance: no cracking after 25 cycles of freezing and thawing(GB/T7019-1997)

Radioactivity: standard of BG6566-2001 Class-A Decoration materials.

Size & Loading Quantity of fiber cement board:

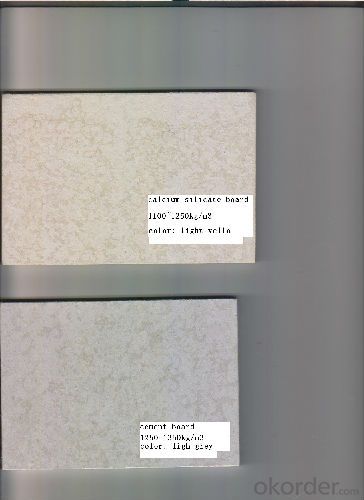

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS | Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS | Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS | Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS | Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS | Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS | Single, double surface Sanding or tapered |

| 15mm | 1200mm x 2400mm 1220mm x 2440mm | 346 PCS | Single, double surface Sanding or tapered |

| 18mm | 1200mm x 2400mm 1220mm x 2440mm | 294 PCS | Single, double surface Sanding or tapered |

| 20mm | 1200mm x 2400mm 1220mm x 2440mm | 260 PCS | Single, double surface Sanding or tapered |

5,FAQ of (Cement Boards)

Customized sizes and thickness are also produced.

Reccommend application of fiber cement board

Partition board , suspended ceilings,exterior wall cladding, paneling ,light weight grouting panel, interior dry wall decoration board, interior wall after painting and coating.

3.5-6mm : for interior ceiling

7-20mm : for drywall partition

- Q:Iam building a dry stack wall and the home store said to use cement broad and wire mess .

- You mean wire mesh. Yes, you need that.

- Q:I'm putting in a new tub surround this weekend (gutting the bathroom wall and starting from scratch). After I put cement board on the studs and install the tub surround, there will be a space about foot high between the surround and the ceiling. The cement board will be exposed. Can I paint the cement board so it matches the colors of the bathroom? Do I need to buy special paint or something? Obviously, I've never done this sort of thing before and I appreciate any advice I can get.

- i put green board in in 97 and painted it twice. its still good. Green board is 6 foot to 9 feet above standup shower.

- Q:Clothes on the stick asbestos fiber how to do

- If you have asbestos fiber, you can use a transparent tape sticky, can effectively remove fiber impurities, the effect is very good, easy

- Q:installed the most powerful exhaust fan that is made and my newly painted hardi backer walls are sweating when take a shower or bath with the fan running- what can I do?

- is it the outside wall.it may need to be insulated.

- Q:why is gypsum always interground with cement clinker during the final stages of portland cement manufacture?

- Because they are trying to dispose of Gypsum and this is one of the few ways that it can be blended with something else in large quantities. Gypsum is produced as a by-product form the de-sulphurisation of flue gasses from power plants that still burn dirty fuels like coal or oil residues. There is often thousands of tons of this stuff produced every day and it has to be dumped somewhere. Land fill sites are filling up rapidly and charge big fees for disposal so it is very attractivce to belnd it into cement products. Gypsum is also used as the main part of plaster board which is another place to get rid of the unwanted material.

- Q:I'm going to apply cement board over water proof sheet rock,anything special i need to do other than screw it

- Along with the screws I would use liquid nails. One tube per each 4 x 8 sheet.

- Q:I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- I have not seen thinset used under the cement board unless the surface had high/low spots. As long as the area is flat, continue on.

- Q:When I was replacing vanity in small bathroom, I discovered that old vanity was sitting on top of the wooden sub-floor while the rest of the floor (with ceramic tile) is about whole inch above the sub-floor. I'm planning to install tile (never did it before) and I've read that you attach cement backer board to sub-floor and use adhesive to attach tiles. However cement boards are sold in 1/2 thickness. What should I do to make whole sandwich (board, adhesive, tile) to be on the same level as rest of the tile floor? I'd much appreciate any suggestions! :)

- Screw down a piece of 1/2 plywood to the subfloor and then screw down the cement board on top of that. If you are still a tad low you can always spread on a layer of thinset mortar to bring it up to the same height as the rest of the floor. Whenever I do a bathroom I always remove the vanity and tile under it just like the rest of the room. That way, everything is level and if you ever want to replace the vanity with a smaller one or a pedestal sink the floor is good to go. What I have found, and you have found too, is that most people are just too damned lazy to bother doing that.

- Q:My husband fixed the faucet in the tub around two years ago. He cracked one of the tiles. We bandaged the area, but water has been getting behind the tiles. So, we have water damage. Plus, there is this weird white fungus looking stuff that is growing in some of the grout lines. I don't want to just put a liner over this mess. I would like to pull all the tile off and put cement board up (the house is old and it has sheet rock behind the tile), so i can start fresh. Will the liner hold up the same if it is glued to cement board rather than tile?

- I'd remove the tile, the fungus could be mold or mildew and you don't want to trap or seal that in the walls. I the wall board behind is moldy or in bad shape, replace that too with greenboard (water/mildew resistant backerboard)

- Q:Our contractor says green board is required for his corian shower because it is coved and waterproof. Is he right? The City says cement board is a new requirement because mold can get in. However, they will accept the manufacturers recommendation. We want to follow the building code.

- Fibre cement board should be used in showers, bathrooms, and other 'wet areas'

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords