Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

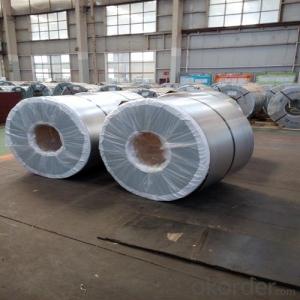

3.Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness Images

4. Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q:How does tinplate contribute to the overall reusability of packaging?

- Tinplate contributes to the overall reusability of packaging due to its durable and long-lasting nature. It can be easily cleaned and reused multiple times without losing its structural integrity, making it an ideal material for packaging that can be used again and again. Additionally, tinplate is highly resistant to corrosion, ensuring that the packaging remains in good condition for extended periods. Its reusability helps reduce waste and promotes sustainable practices in the packaging industry.

- Q:Tinned iron and iron matte tin in difference

- While in tinplate iron or iron matte silver, the surface is sandy, so people often referred to as silver iron, its price is a tin material price is more expensive, generally can usually used without printing packing, for printed cans is usually to is sandy, it is generally. Iron printing, matte iron tensile and hardness of tin iron generally not good, some specifications of tinplate is not suitable for stretching relatively large.

- Q:What's the difference between iron, aluminium, stainless steel, galvanized iron and tin?

- Aluminum is a kind of material. It is not easy to be oxidized when it meets water. The price is moderateStainless steel is another kind of material. It is not easy to be oxidized when it meets water. The price is high

- Q:Can you tell me how to deal with the recycling of tinplate?

- The tin is magnetic, is easy to recycle scrap. Second, waste tin as scrap iron and steel melted, make steel containing a small amount of tin (less than 0.1%), to improve the performance of cast iron.

- Q:Can tinplate packaging be used for home decor products?

- Yes, tinplate packaging can be used for home decor products. Tinplate is a versatile material that can be easily molded into various shapes and sizes. It provides durability, visual appeal, and can be customized to suit different home decor styles. Additionally, tinplate packaging offers excellent protection for fragile home decor items, making it a suitable choice for packaging and displaying such products.

- Q:Can tinplate be used for HVAC systems?

- Yes, tinplate can be used for HVAC systems. Tinplate is a commonly used material in the construction of ductwork and air handling units due to its corrosion resistance, durability, and ease of fabrication. It provides a reliable and cost-effective solution for HVAC applications.

- Q:Can tinplate be used for packaging of sensitive electronic components?

- Yes, tinplate can be used for packaging of sensitive electronic components. Tinplate provides excellent protection against moisture, corrosion, and electromagnetic interference, making it a suitable material for safeguarding sensitive electronics during transportation and storage. Additionally, tinplate's durability ensures that the components remain intact and undamaged.

- Q:Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

- Q:What are the different coatings used on tinplate?

- There are several different coatings used on tinplate, including tin-free steel (TFS) coating, electrolytic tinplate (ETP) coating, lacquer coating, and organic coatings. These coatings serve different purposes such as corrosion resistance, food safety, and enhanced visual appeal.

- Q:How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition in several ways. Firstly, tinplate acts as a barrier between the ammunition's metallic components and the environment, preventing corrosion and ensuring the ammunition remains functional over time. Additionally, the smooth surface of tinplate reduces friction and enhances the flow of ammunition through firearms, improving the overall reliability and performance of the weapon. Furthermore, tinplate's strength and durability provide necessary protection to the ammunition during handling, transportation, and storage, ensuring it remains intact and ready for use when needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate of Prime Quality for Metal Containers Use 0.30mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords