DOP,DBP,ESO,DEDB,Chlorinated Rubber,PLASTICIZER

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

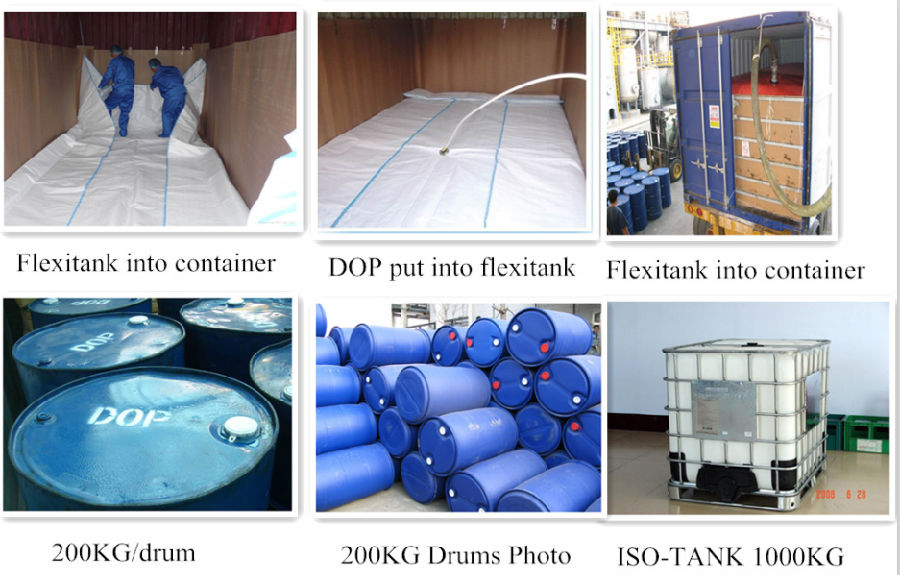

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q:Why the catalyst after the chemical reaction of its quality and chemical properties unchanged

- In fact, the catalyst in the reaction process has become other substances, but after the end of the reaction, the catalyst has changed back. That is, the catalyst is actually involved in the reaction, except that the amount of catalyst being reacted is as much as it did.

- Q:Chemical "catalyst can speed up the chemical reaction rate of other substances," this sentence right?

- Wrong, the catalyst is divided into two kinds, one is to speed up the chemical reaction speed, and the other is the opposite

- Q:What is the nature of the chemical catalyst?

- Can only speed up or slow down the reaction rate, can not change the reaction balance,

- Q:In the chemical reaction, why can the catalyst speed up the reaction rate

- V2O5 (vanadium pentoxide) catalyzes the oxidation of sulfur dioxide to sulfur trioxide, and no catalyst is difficult to occur.

- Q:Chemical Reactions Under what circumstances the catalyst accelerates the reaction

- First, more than ninety-nine percent of the catalyst is accelerating the reaction, and if the catalyst kinetics reduces the energy barrier of the reaction, the reaction will naturally accelerate.

- Q:The "one-to-two change" of the catalyst is that the quality and chemical properties of the reactants are constant or the quality and chemical properties of the catalyst are constant?

- The change in chemical reaction rate is the same as the chemical nature and quality

- Q:Like biological and industrial reations. Thanks.

- Reactions that have high Activation Energy need catalysts to speed up reactions. These reactions aren't spontaneous since the reactants do not have enough energy to overcome the activation energy barrier. Catalysts are compounds that speed up reactions by providing an alternative pathway for the reaction. It is a common misconception that catalysts lower the activation energy. It doesn't actually lower the activation energy, instead it provides an alternative pathway with lower activation energy. For example, breakdown of hydrogen peroxide happens in nature but, relatively slowly. When you add a little bit of manganese dioxide, the breakdown happens a lot faster. Another example is, breakdown of glucose in the body. It is facilitated by an enzyme called amylase (or carbohydrase). An industrial example is the use of vanadium pentoxide (V2O5) in the Contact process, where SO2 is converted to SO3 in the presence of V2O5. Hope that helps!

- Q:explain how a catalyst can affect the rate of reaction but not be in the overall equation.?

- Catalysts act to increase the rate of reaction, for example by providing an alternative reaction pathway which lowers the activation energy of the reaction i.e. increasing the likelihood of successful collisions between the reactants. However, they are not used up during the course of the reaction, and at the end you have exactly the same mass of catalyst as you started with, unlike the reactant(s), which will be used up to form product(s). So, the overall equation of the reaction does not include the catalyst because it only needs to show the substances which are used up or formed during the course of the reaction i.e. the reactants and products.

- Q:Just something I've always wondered about...

- activation energy has got nothing to do with this. the main reason that the transition metal oxides are catalysts is that they have vacant d orbitals. the reagents are adsorbed on the metal surface and the d orbitals serve as a sort of clamp between the substrates and reagents. for example if you consider the hydrogenation of ethylene in palladium catalyst here the d orbitals lead to syn addition of hydrogen by clamping the pi electron cloud . this is a sort of chemisorption.

- Q:I opened catalyst control center to see what its was, i didn't change anything and now when i full screen a youtube and hulu the screen will be black and the loading bar at the bottom will be stuck. I also noticed that now when i play minecraft all the blocks have a black out line i cant get rid of. I tried deleting my .minecraft and that didn't fix it.

- Catalyst control center? You, my friend, have a Radeon graphics card. What's happening is that somewhere you have Anti-Aliasing turned on. Go back into your catalyst control center and anywhere where there is an option to 'use application settings'- select it. It's supposed to improve your graphics quality, but there are a lot of bugs with it on a whole bunch of applications and games- including Minecraft. Oh, and as for the youtube thing- alt+tab should show you where your video has disappeared to. Yes, I know- it's bloody weird, but flash is buggy as heck, and Radeon graphics cards are weird; I should know- I have one too! That should do the trick! If it doesn't work then there's likely an extra option somewhere that you haven't ticked to 'use application settings'.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DOP,DBP,ESO,DEDB,Chlorinated Rubber,PLASTICIZER

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords