Directly Buried Ground Mounting System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

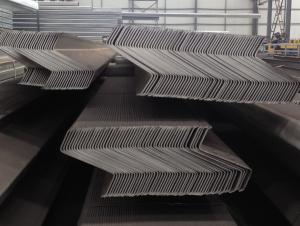

Directly Buried Ground Mounting System is applicable to be the photovoltaic array system on the open field.This system is designed to be steady and safety complied with the structural mechanics and construction acts.

For the difference foundation solutions, such as concrete with pre-buried bolt, direct buried and ground screw, the system can be modified to be installed.Its material, include the hot galvanized steel and anodized aluminum alloy, is all have high anti-corrosive for using outdoor.

According to the practical requirement, The system could be planned and customized on the factory to eliminate thewelding and cut onsite to save your time and money.

Features:

Install site:Open ground

Tilt Angle:10~60deg

System Height:<2.5m

Max Wind Speed:<60m/s

Snow Load:<1.4KN/㎡

Standard:AS/NZS 1170 and other international Standard

Material:Aluminum alloy Al6005-T5& Stainless steel 304 & Hot galvanized steel

Anticorrosive:Anodized & Hot galvanized

Color:Natural or Optional

Warranty:Ten years warranty and up twenty years service life

- Q:Can solar mounting systems be installed on green roofs?

- Yes, solar mounting systems can be installed on green roofs. Green roofs are designed to support the weight of vegetation and provide insulation, and with proper planning and engineering, solar panels can be safely installed on top of them. This allows for the dual benefits of utilizing renewable energy while maximizing the use of available space.

- Q:Can solar mounting systems be installed on rooftops with rooftop safety rails?

- Yes, solar mounting systems can be installed on rooftops with rooftop safety rails. The safety rails can provide additional protection and support for the solar panels, ensuring a safe and secure installation.

- Q:Can a solar mounting system be installed on a brewery or distillery?

- Yes, a solar mounting system can certainly be installed on a brewery or distillery. These systems are versatile and can be installed on various types of structures, including commercial buildings like breweries and distilleries. The installation of a solar mounting system can help these establishments offset their energy consumption and reduce their carbon footprint.

- Q:Can a solar mounting system be used with solar-powered planes?

- No, a solar mounting system cannot be used with solar-powered planes. Solar mounting systems are designed to support and position solar panels on the ground or on rooftops, whereas solar-powered planes have their own custom-built structures to house and integrate solar panels for generating power.

- Q:Can a solar mounting system be used in areas with limited access to water supply?

- Yes, a solar mounting system can be used in areas with limited access to water supply. Solar mounting systems typically do not require water for their operation or maintenance. They are designed to harness solar energy and convert it into electricity, without the need for water-based cooling or cleaning systems. As long as there is sufficient sunlight, a solar mounting system can be installed and used effectively in areas where water supply is limited.

- Q:Can a solar mounting system be used in areas with solar incentives for universities?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for universities. In fact, it is highly recommended for universities to take advantage of these incentives and install solar panels to reduce their carbon footprint and save on energy costs. A solar mounting system provides the necessary support and stability for solar panels, allowing universities to efficiently harness solar energy and benefit from the available incentives.

- Q:Can a solar mounting system be used in areas with solar incentives for breweries?

- Yes, a solar mounting system can be used in areas with solar incentives for breweries. These incentives often include financial incentives, tax credits, and other benefits that encourage the adoption of solar energy. By installing a solar mounting system, breweries can take advantage of these incentives to offset their energy costs and promote sustainability.

- Q:Can a solar mounting system be used on flat ground surfaces?

- Yes, a solar mounting system can be used on flat ground surfaces. In fact, ground-mounted solar systems are commonly installed on flat or gently sloping terrains to maximize energy production and ease installation.

- Q:Can a solar mounting system be used in areas with limited access to financing options?

- Yes, a solar mounting system can be used in areas with limited access to financing options. In such cases, alternative financing models like community solar projects, microfinance, and leasing arrangements can be explored to make solar installation more accessible and affordable for individuals and communities with limited financing options. Additionally, government incentives and subsidies can also play a crucial role in promoting solar adoption in these areas.

- Q:Can a solar mounting system be installed on a rooftop with a modified bitumen roof?

- Yes, a solar mounting system can be installed on a rooftop with a modified bitumen roof. Modified bitumen roofs are commonly used in commercial and residential buildings and can support the weight of solar panels and the mounting system. However, it is crucial to consult with a professional installer to ensure that the mounting system is properly installed and secured to the roof, taking into consideration the specific requirements and characteristics of the modified bitumen roof.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Directly Buried Ground Mounting System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords