Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

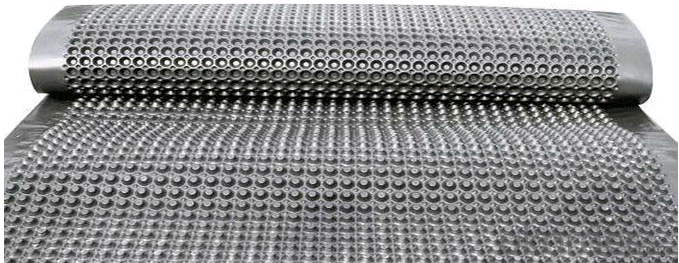

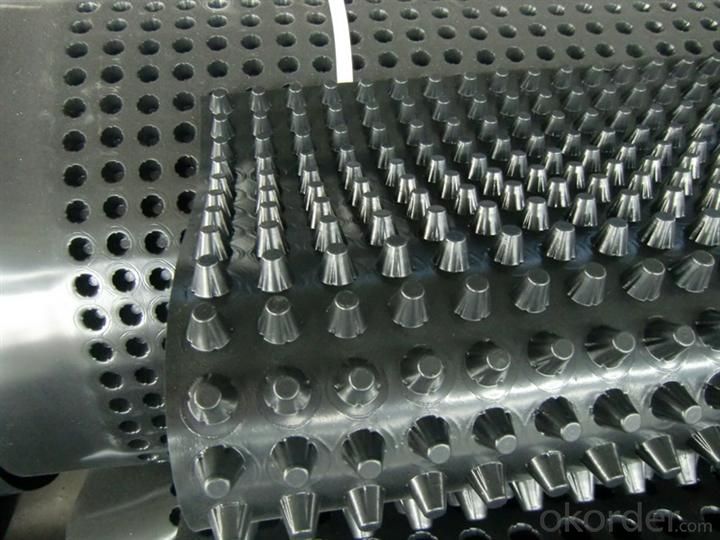

EltMembrane-CDG series of geomembrane is manufactured from High Density Polyethylene resins. Produced by extruding plastic sheet into dimple shape.These dimples,in spatial structure with certain height. Can resist long-term high pressure without deformation. On the top of the dimples, there is filtration geotextile to make sure the drainage channel ruing well without any block for any articles. For example,filling particles or concrete.

Advantages

1. strong viscosity, cold pressing sensitive

2. color white/black

3. accurate size cutting

4. custom size offered without any surcharge

Application

1, Municipal projects

2,Landfill treatment projects

3,Waste water treatment

4,Mineral waterproofing

| Composite Dimple geomembrane | |||||||

| NO. | Item Name | Technical requirements | |||||

| H10-1.0 | H20-1.0 | H10-1.5 | H20-1.5 | H10-2.0 | H20-2.0 | ||

| 1 | Tensile strength N/<5cm> ≥ | 400 | 400 | 500 | 500 | 700 | 700 |

| 2 | Elongation at break % ≥ | 200 | 200 | 300 | 300 | 400 | 400 |

| 3 | Dimensional strength Mpa ≥ | 400 | 320 | 450 | 370 | 500 | 420 |

| 4 | Dimensional stability % | ±2 | |||||

| 5 | Low tempreture impact brittle property | -35℃ crack-free bending | |||||

| 6 | Longitudinal flow capacity cm3/s( hydraulic pressure 5Kpa) | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

| 7 | Longitudinal flow capacity cm3/s( hydraulic pressure 350Kpa) | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

FAQ

Q: Can you accept sample order?

A: Yes, we are willing to send small samples for free, while the shipping fee should be afforded by yourself.

Q: What is your delivery time?

A: 1 days for samples, two weeks for mass production.

Q: What is your payment terms?

A: T/T , L/C, Western Union, Money Gram. 30% advance before producing, 70% payment before deliverying.

Q: How can I get my order?How can I know you sent the goods.

A: We will send you the goods by UPS, DHL, Fedex, Oversea Shipment or other forwarder,

all with tracking number or B/L.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:how is the metal plating ceramic film?

- Further improve separation precision and stability of the ceramic membrane materials to achieve continuous and efficient operation at nanoscale level in liquid separation field as well as in the field of gas separation. anti temperature ceramic separation materials of large aperture and high porosity so as to achieve long term and stable gas-solid separation in the field of efficient use of resources and environmental protection. to achieve treatment of the ceramic film surface and expand the application scope by changing hydrophilia and hydrophobicity of the surface and charge performance, biology compatibility.

- Q:What are the requirements for geomembranes used in desalination plants?

- Geomembranes used in desalination plants have specific requirements to ensure their effectiveness and longevity. Some of the key requirements for these geomembranes include: 1. Chemical resistance: They must be resistant to the harsh chemicals used in the desalination process, such as chlorine, saltwater, and various cleaning agents. 2. Durability: Geomembranes should have high tensile strength and puncture resistance to withstand the rigorous conditions and potential mechanical stresses within the plant. 3. Low permeability: They need to have a low permeability rate to prevent the leakage of water or chemicals, ensuring efficient water treatment. 4. UV resistance: Since desalination plants are often located in sunny environments, geomembranes should be UV resistant to withstand prolonged exposure to sunlight without degradation. 5. Flexibility: The geomembranes should be flexible enough to adapt to the various shapes and contours of the desalination plant structures, including tanks, basins, and pipelines. 6. Temperature resistance: They should be able to withstand the temperature fluctuations that occur in the desalination process, including exposure to high temperatures during preheating or sterilization. 7. Compliance with regulations: Geomembranes used in desalination plants must meet relevant industry standards and regulations, such as those set by the International Organization for Standardization (ISO) and local water quality agencies. Meeting these requirements ensures that the geomembranes effectively contain and protect the water and chemicals involved in the desalination process, promoting efficient and sustainable water treatment.

- Q:Can geomembranes be used in landfill gas collection systems?

- Yes, geomembranes can be used in landfill gas collection systems. Geomembranes are impermeable liners made of synthetic materials that are designed to prevent the leakage of liquids and gases. In landfill gas collection systems, geomembranes are used as a barrier to contain and collect the methane gas produced by decomposing waste in landfills. They help to prevent gas migration and facilitate the efficient collection and extraction of landfill gas for energy generation or other uses.

- Q:What is geocell

- The geocellgeocell is formed by strengthening the HDPE sheet material, which is formed by the high strength welding, and the soil chamber is welded by ultrasonic needle. Because of the engineering needs, and some punch on the mebrane

- Q:What is the operating principle of the vacuum laminating machine?

- The laminating machine must be the plastic packaging machine. The working principle is to insert the materal (or paper) to be plastic coated into the special plastic package, put the material into the plastic packaging machine, melt and solidfy the adhesive of the plastic package by heating and pressing and exhaust the air at the same time. By then plastic packaging is completed.

- Q:How to install the piamater ceiling

- 1. According to the design requirements of the drawings, in where is needed the installation of soft film smallpox height level Four around a fixed ring 4X4Cm keel support (wood or steel). (see construction design drawing). Note: some areas are relatively large that it requires to install the sub block so as to achieve good effect. This is required to add a wood beam in the central. This is to make a process according to the actual situation. 2. When all the required wooden blade fixed, then to install the aluminium alloy keel to fix the bottom of soft film smallpox.

- Q:What are the reasons for the damage of geomembrane?

- depend on the specific project, used thickness, whether the geomembrane is produced by new material and whether the protective layer of geomembrane meets the construction requirements

- Q:How do geomembranes contribute to the conservation of water resources?

- Geomembranes contribute to the conservation of water resources by acting as a barrier that prevents water from seeping into the ground or escaping from containers. They are used in various applications such as lining reservoirs, ponds, and canals, preventing water leakage and reducing evaporation. By effectively containing and preserving water, geomembranes help to conserve this vital resource and ensure its availability for various purposes like agriculture, drinking water, and industrial use.

- Q:What are the advantages of using geomembranes in biogas systems?

- There are several advantages of using geomembranes in biogas systems. Firstly, geomembranes act as a barrier, preventing the leakage of biogas into the surrounding environment, thus reducing the risk of greenhouse gas emissions. Secondly, they help in the retention and concentration of biogas, improving the overall efficiency of the system. Additionally, geomembranes are durable and resistant to chemical degradation, ensuring a longer lifespan and lower maintenance costs. Lastly, they provide flexibility in system design, allowing for easy installation and customization according to specific project requirements.

- Q:How do geomembranes contribute to the prevention of soil erosion in construction sites?

- Geomembranes contribute to the prevention of soil erosion in construction sites by acting as a barrier between the soil and the surrounding environment. These impermeable sheets are placed on the surface of the soil, preventing water from infiltrating and carrying away the topsoil. This helps to maintain the stability of the construction site, reducing the risk of erosion and preserving the integrity of the soil.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords