Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Roofing Sheet/Color Coated Steel Coil/ppgi

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

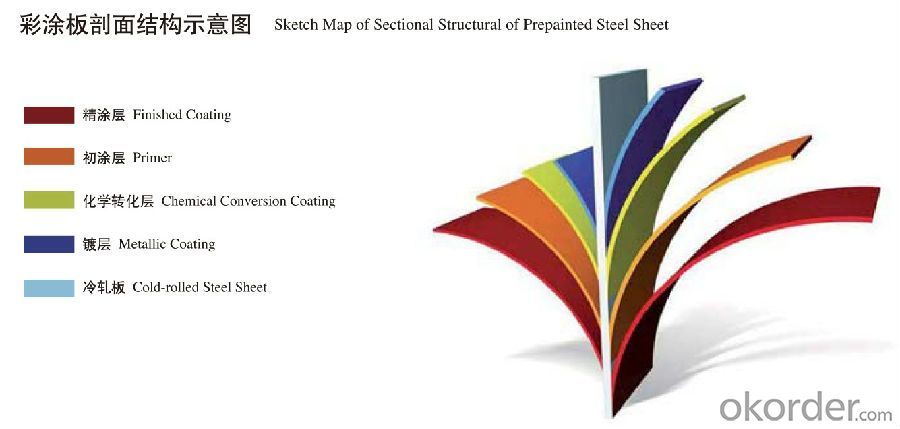

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4. Image:

5. Production Line

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What are the different types of edge treatments for steel coils?

- There are several different types of edge treatments for steel coils, each serving a specific purpose and providing different benefits. 1. Slit Edge: Slit edge is the most common type of edge treatment for steel coils. It is achieved by cutting the coil along its width, resulting in two distinct edges. Slit edges are generally smooth and free from burrs, making them suitable for most applications. 2. Mill Edge: Mill edge is the untreated edge of a steel coil as it comes from the rolling mill. It is characterized by a rough and uneven surface, with visible imperfections such as burrs and irregularities. Mill edges are typically not suitable for direct use and require further processing or trimming to achieve a desired edge quality. 3. Trimmed Edge: Trimmed edge is an edge treatment that involves removing the rough and irregular portions of the mill edge. This process is done through shearing or cutting, resulting in a smoother and more consistent edge. Trimmed edges are commonly used when a clean and uniform appearance is required. 4. Deburred Edge: Deburring is a process that removes any sharp or rough edges from the steel coil. This treatment is essential for applications where safety is a concern, as it eliminates the risk of injury from handling sharp edges. Deburred edges are achieved through grinding or filing and provide a smooth and safe edge for various applications. 5. Rounded Edge: Rounded edge is a type of edge treatment that involves rounding the sharp corners of the steel coil. This treatment is often used to prevent damage to other materials or surfaces during handling or transportation. Rounded edges reduce the risk of scratches, dents, or other forms of surface damage. 6. Beveled Edge: Beveled edge is an edge treatment where the edge of the steel coil is cut at an angle, typically 45 degrees. This type of treatment is commonly used in applications that require a tight fit or seamless joint with other components. Beveled edges allow for easier assembly and improve the overall appearance of the final product. Each of these edge treatments has its own advantages and is chosen based on the specific requirements of the application. The selection of an appropriate edge treatment for steel coils is crucial to ensure optimal performance, safety, and aesthetics in various industries such as construction, manufacturing, automotive, and more.

- Q:What is the minimum temperature that steel coils can withstand?

- The minimum temperature that steel coils can withstand depends on the specific grade of steel and its intended application. However, in general, most steel coils can withstand temperatures as low as -40°C (-40°F) without significant damage or structural failure.

- Q:hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Steel is made from injecting air into molten iron

- Q:What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. However, it is typically measured in millimeters or inches, ranging from a few tenths of a millimeter to several millimeters.

- Q:where can you find carbon steel in los angeles?? what store?? preferabbly 01 carbon steel

- Try the internet. I'm sure the steel suppliers there know about this

- Q:What are the different methods of coil flattening for steel coils?

- Coil flattening for steel coils can be achieved through various methods, each having its own advantages and limitations. Some commonly employed techniques are as follows: 1. Roller leveling: By passing the steel coil through a series of rollers that exert pressure, this method flattens the coil. The rollers can be adjusted to achieve the desired level of flatness. Roller leveling is a versatile approach capable of handling a wide range of coil sizes and thicknesses. 2. Precision leveling: This method employs a more advanced leveling machine that applies pressure to specific areas of the coil to eliminate any waviness or defects. Precision leveling is commonly used for high-quality steel coils that require exceptionally flat surfaces. 3. Stretch leveling: Also known as tension leveling, this technique involves stretching the steel coil beyond its yield point, causing permanent deformation and flattening. Stretch leveling is frequently used for thinner gauge coils and effectively eliminates coil set and crossbow defects. 4. Temper rolling: This method subjects the steel coil to a controlled low-temperature heat treatment followed by cold rolling. The combination of heat and cold rolling helps relieve internal stresses and improve flatness. Temper rolling is particularly suitable for coils that require enhanced surface quality. 5. Laser flattening: This advanced method utilizes laser technology to selectively heat and flatten specific areas of the coil. Laser flattening is highly precise and capable of correcting localized defects or unevenness. However, due to its higher cost, it is typically used for smaller coils. It is essential to consider various factors, such as desired flatness requirements, coil dimensions, material properties, and production budget, when selecting the most appropriate coil flattening method.

- Q:How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through various methods. These include visual inspection, dimensional measurements, and mechanical tests such as tensile and impact tests. Additionally, chemical composition analysis is performed to ensure that the steel meets the required specifications. These comprehensive tests ensure that the steel coils are of high quality and meet the standards set by the industry.

- Q:How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as they serve as the raw material for manufacturing these components. The coils are processed through various manufacturing steps, such as cutting, stamping, and forming, to shape them into the desired latch design. These transformed steel coils are then further treated with coatings or finishes to enhance their durability and corrosion resistance. Ultimately, steel coils play a crucial role in providing the base material necessary for creating sturdy and functional steel latches.

- Q:How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q:Can steel coils be recycled?

- Yes, steel coils can be recycled. Steel is a highly recyclable material, and recycling steel coils helps to conserve natural resources and reduce environmental impact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords