All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

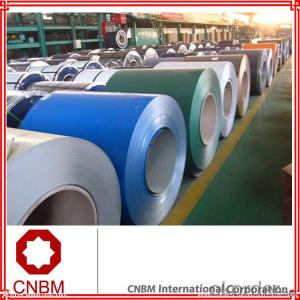

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different forming techniques for stainless steel coils?

Some of the different forming techniques for stainless steel coils include cold rolling, hot rolling, annealing, and slitting.

What is the difference between mill finish and polished finish stainless steel coil?

The main difference between mill finish and polished finish stainless steel coil is the surface appearance. Mill finish stainless steel has a rough, unpolished surface, while polished finish stainless steel has a smooth, shiny surface achieved through polishing processes.

What are the properties of stainless steel coils?

Stainless steel coils have several key properties that make them highly desirable in various industries. Firstly, they exhibit excellent corrosion resistance, making them resistant to rust and stains even in harsh environments. Secondly, stainless steel coils possess high tensile strength and durability, making them resistant to deformation and capable of withstanding heavy loads. Additionally, they have a high melting point, allowing them to retain their structural integrity even at elevated temperatures. Stainless steel coils also offer good formability, enabling them to be easily shaped and fabricated into various products. Lastly, they have a visually appealing and hygienic surface finish, making them suitable for applications where aesthetics and cleanliness are important, such as in the food and beverage industry.

Can stainless steel coils be hardened or tempered?

Yes, stainless steel coils can be hardened or tempered. Both processes involve heating the stainless steel to a specific temperature and then cooling it rapidly or slowly to achieve the desired hardness or strength. Hardening increases the hardness and strength of the stainless steel, while tempering reduces brittleness and improves toughness.

How does sandblasting affect the surface of a stainless steel coil?

Sandblasting can significantly affect the surface of a stainless steel coil. The high-pressure abrasive particles used in sandblasting can remove any existing surface contaminants, such as rust or paint, and create a more uniform and clean surface. Additionally, sandblasting can create a textured or roughened surface, which can enhance the adhesion of coatings or paints applied to the stainless steel coil.

Wholesale Stainless Steel Coil from supplier in Russia

With a strong emphasis on customer satisfaction, we strive to meet and exceed your expectations. Our team of experienced professionals is dedicated to providing personalized assistance throughout the entire purchasing process. We understand the unique requirements of the Russian market and work closely with our customers to ensure that their specific needs are met.

Our Stainless Steel Coils are sourced from reputable manufacturers and undergo rigorous quality control measures to guarantee their reliability and durability. We offer a wide range of grades, sizes, and finishes to accommodate various applications and industries. Whether you require coils for construction, automotive, or manufacturing purposes, we have the right solution for you.

In addition to our high-quality products, we also provide competitive pricing and flexible delivery options. We understand the importance of timely delivery and strive to meet your project deadlines. Our logistics team works closely with reliable shipping partners to ensure that your Stainless Steel Coils are delivered safely and efficiently.

At CNBM, we are committed to building long-term partnerships with our customers. We believe in fostering strong relationships based on trust, transparency, and mutual success. Our dedicated customer support team is always available to address any queries or concerns you may have.

If you are looking for a reliable supplier of Stainless Steel Coils in Russia, we are here to assist you. Contact us today to discuss your requirements and experience our exceptional services firsthand.

Our Stainless Steel Coils are sourced from reputable manufacturers and undergo rigorous quality control measures to guarantee their reliability and durability. We offer a wide range of grades, sizes, and finishes to accommodate various applications and industries. Whether you require coils for construction, automotive, or manufacturing purposes, we have the right solution for you.

In addition to our high-quality products, we also provide competitive pricing and flexible delivery options. We understand the importance of timely delivery and strive to meet your project deadlines. Our logistics team works closely with reliable shipping partners to ensure that your Stainless Steel Coils are delivered safely and efficiently.

At CNBM, we are committed to building long-term partnerships with our customers. We believe in fostering strong relationships based on trust, transparency, and mutual success. Our dedicated customer support team is always available to address any queries or concerns you may have.

If you are looking for a reliable supplier of Stainless Steel Coils in Russia, we are here to assist you. Contact us today to discuss your requirements and experience our exceptional services firsthand.