Continuous Casting Aluminium Circle for Kitchen Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

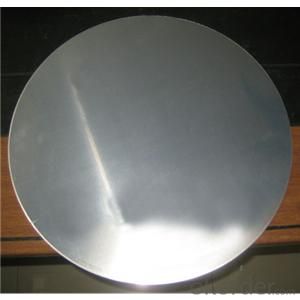

1.Structure of Continuous Casting Aluminium Circle for Kitchen Cookware

Continuous Casting Aluminium Circle for Kitchen Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Circle for Kitchen Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.

- Q:Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Indeed, the utilization of aluminum sheets is appropriate for the production of aircraft fuselages. Aluminum remains a favored selection for aircraft assembly owing to its exceptional strength-to-weight proportion, ability to withstand corrosion, and simplicity in fabricating. Its lightweight nature aids in the reduction of the aircraft's total weight, thereby enhancing fuel efficiency and augmenting payload capacity. Moreover, aluminum exhibits remarkable resilience in enduring the pressures and tensions encountered during flight. Furthermore, it is a readily accessible and economically viable material, rendering it a pragmatic preference for aircraft manufacturers.

- Q:i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- LEAD

- Q:What are the different methods of surface texturing aluminum sheets?

- There are several methods of surface texturing aluminum sheets, each with its unique advantages and applications. 1. Mechanical Texturing: This method involves the use of mechanical tools or processes to create patterns or textures on the surface of aluminum sheets. Examples include brushing, sanding, or embossing. Mechanical texturing is commonly used to create a matte or brushed finish on aluminum sheets, which enhances their aesthetic appeal and hides surface imperfections. 2. Chemical Texturing: Chemical texturing involves the use of chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching is a common chemical texturing method that involves immersing the aluminum sheet in an acid solution to selectively dissolve the surface and create a textured surface. Chemical texturing is often used to improve the adhesive properties of aluminum sheets, making them suitable for bonding or coating applications. 3. Anodizing: Anodizing is an electrochemical process that creates a controlled oxide layer on the surface of aluminum sheets. This process can be used to create a variety of surface textures, ranging from a smooth, glossy finish to a rough, matte finish. Anodizing not only provides a textured appearance but also enhances the corrosion resistance and durability of the aluminum sheet. It is commonly used in architectural applications, consumer products, and automotive parts. 4. Laser Texturing: Laser texturing involves the use of laser technology to create precise and intricate patterns or textures on the surface of aluminum sheets. Laser beams can be precisely controlled to remove material or modify the surface in a desired pattern, allowing for highly customizable and detailed textures. Laser texturing is often used in decorative or high-end applications, such as jewelry, signage, or interior design. Each method of surface texturing aluminum sheets offers unique benefits and is suitable for different applications. The choice of texturing method depends on factors such as the desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

- Q:Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. It is a commonly used material due to its high thermal conductivity, lightweight nature, and excellent heat resistance properties.

- Q:What are aluminum sheets?

- Aluminum sheets are thin, flat pieces of aluminum that are commonly used in various industries and applications. They are made from aluminum, which is a lightweight and versatile metal known for its exceptional strength, durability, and corrosion resistance. These sheets can range in thickness, width, and length, depending on the specific requirements of the project. Aluminum sheets are widely used in construction, automotive, aerospace, packaging, and manufacturing industries, among others. They are used for a multitude of purposes such as roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. The flexibility and malleability of aluminum allow for easy shaping and forming, making it a popular choice for a wide range of applications. Additionally, aluminum sheets can be coated or finished to further enhance their appearance or protect them from external factors such as moisture, UV rays, or chemicals. Overall, aluminum sheets are essential materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for various industrial and commercial uses.

- Q:What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets can be influenced by a range of factors including the individual thickness of each sheet, the level of purity in the aluminum, and the potential presence of impurities or alloying elements. Typically, aluminum is recognized for its relatively superior electrical conductivity when compared to other metals. Nevertheless, without specific details regarding these aforementioned factors, it becomes challenging to provide an exact measurement for the electrical conductivity of 101 aluminum sheets.

- Q:How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q:I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

- Q:Can aluminum sheets be custom cut to specific dimensions?

- Yes, aluminum sheets can be custom cut to specific dimensions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Continuous Casting Aluminium Circle for Kitchen Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords