Colored Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Glass is made of high quality float glass, coated glass of various colors, Low-E glass, tempered glass, thermo-strengthening glass and bent/tempered glass. It is a product integrated with two or more glass sheets and one or more layers of organic polymers like PVB, EVA, SGP, etc. It is processed by the tablet machine under high pressure and high temperature, making it unite into one lastingly.

Features of Colored Laminated Glass:

1. Safety glass

2. Fine light control and heat insulation when using coated glass

3. Sound insulation and noise reduction

4. Good structural feature

5. In order to guarantee the quality of laminated glass, the PVB films are imported from Dupont of the USA or Sekisui of Japan.

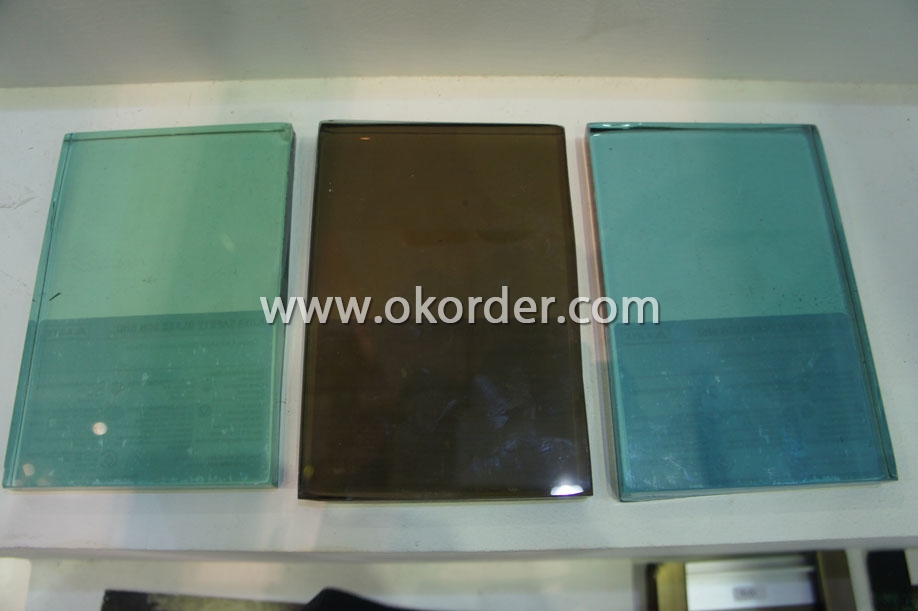

6. The colors of the films include clear, milk, blue, dark grey, light green, bronze, etc.

Specifications of Colored Laminated Glass:

Thickness of Glass: 3mm+3mm; 4mm+4mm; 5mm+5mm; 6mm+6mm; 8mm+8mm; 10mm+10mm; 12mm+10mm

Thickness of PVB film: 0.38-3.04mm

Size:

Min Size: 300*300mm

Max Size: 3000*8000mm

customized size

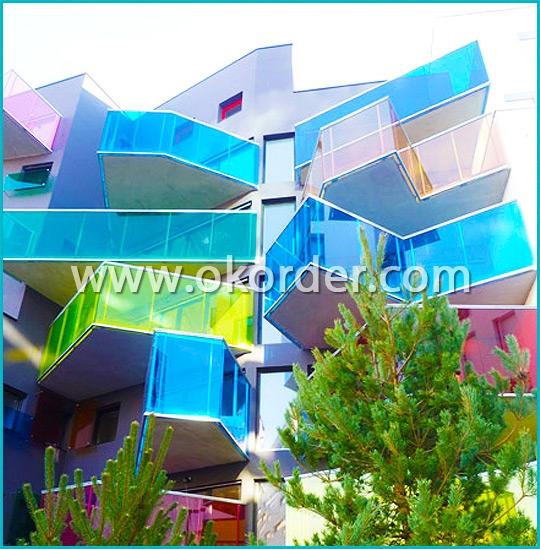

Applications of Colored Laminated Glass:

Laminated Glass is applied in curtain walls, hotels, banks, airports, sunshades, lighting roofs, windows and gates, sprung roofs, indoor glass partitions, glass furniture, show windows, bars, jewelry shops, elevators and so on.

- Q:Use of glass flake cement

- It has good compatibility and can be used as anticorrosive paint with various resins. Word of mouth

- Q:Tile selection, paving process

- The stone used for indoor ground is generally polished board, the thickness of the plate is about 20 millimeters, and now there are thin plates, the thickness is about 10 millimeters, suitable for family decoration. Each block is 300 mm x 300 mm, ~500 mm * 500 mm. Plates and 1:2 cement mortar can be used with 107 adhesive plaster.

- Q:Can the toughened glass be cracked by the sun?

- high strengthThe toughened glass of the same thickness has 3~5 times the impact strength of ordinary glass, and the bending strength is 3~5 times of that of ordinary glass.

- Q:Samsung LCD panel information

- Landlord, you take this screen is not the LCD screen, and the other is the plasma screen.It should be a 46 inch plasma TV set.

- Q:List and characteristics of chimney glass flake cement

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale made of C- glass has excellent chemical durability.

- Q:Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Glass raw materials are: soda ash, limestone, quartz, the ratio is: 1:1:6

- Q:What's the price of 0.85mm thick plexiglass, please?

- Import plate material is better, about 900, but the price is more expensive, generally do not consider adopting, unless their own customers request, and canAt an accepted price.

- Q:What is the ratio of raw materials for glass mildew proof powder?

- Environmental protection standards, with the domestic high-end glass development needs, coconut shell materials are gradually replaced by its excellent performance after falling green traditionChemical mildew proof isolating material.Applicability: (1) glass against mildew; II. Glass anti scratch;Other special applicability:Solid desiccant; plant cultivation raw material, animal feed, etc.; colloid filling material; catalyst carrier; impurity and harmful gas dispel;

- Q:Does fiberglass contain formaldehyde? I'm a hair salon. Buy a glass fiber reinforced plastic shampoo bed, there is always a pungent smell of the body, there is no harm to it, including formaldehyde free

- The pungent smell is not necessarily formaldehyde, and FRP is also called GRP, that is, fiber reinforced plastics, generally refers to glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix.

- Q:Glass raw materials processing equipment, glass raw materials crushing equipment prices generally sell how much?

- Glass raw material processing technology and equipment, advanced at present, glass raw material (quartz sandstone, feldspar, silica) processing generally adopts the following process: A, wet rodmill; B, by the back breaking or jaw crusher and roll composed of multi-stage crushing and screening line.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2008 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | Northern Europe, Africa |

| Company Certifications | Certificate for China Compulsory Product Certification |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Colored Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords