Color Coated Aluminium Sheet AA3003 for ACP Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coated Aluminium Sheet AA3003 for ACP Panel

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet AA3003 for ACP Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet AA3003 for ACP Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

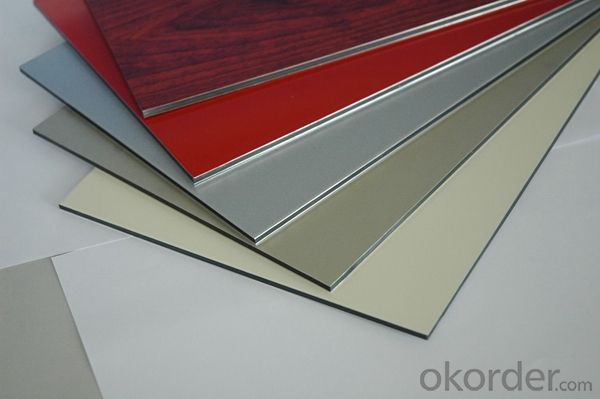

5. Image of Color Coated Aluminium Sheet AA3003 for ACP Panel

6. Package and shipping of Color Coated Aluminium Sheet AA3003 for ACP Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be used for solar panel applications?

- Indeed, solar panel applications can make use of aluminum sheets. Thanks to its lightweight nature, strength, and resistance against corrosion, aluminum is widely favored for solar panel frames and mounting systems. Moreover, its recyclability renders it an eco-friendly choice. By providing structural support and stability, aluminum sheets enable solar panels to endure diverse weather conditions and maintain longevity. Furthermore, aluminum's excellent thermal conductivity aids in dissipating heat generated by the solar panels, thereby enhancing their overall performance and efficiency.

- Q:Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q:1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q:So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q:General characteristics of pure aluminium plate of pure aluminium plate

- Comparison of pure aluminium sheets:1, grade: 1A85, 1A90, 1A93, 1A97, 1A99;Product type: plates, belts, foils, tubes;Main characteristics: Industrial high-purity aluminum;Applications: mainly used in the production of various electrolytic capacitor foil, acid fast container, etc., products have plates, belts, foils and so on.2, grade: 1060, 1050A, 1035;Product type: foil, wire;Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but the strength is low, it can not be strengthened by heat treatment, cutting is not good. Acceptable contact welding and gas welding;Scope of application: use the advantages of making some structures with specific properties, such as aluminum foil gasket and capacitor, electronic tube isolation network, wire and cable protective sleeve, net, wire core and aircraft parts and trim ventilation system.3, brand: 1100;Product type: Sheet & strip;Main features: for ordinary industrial pure aluminum aluminum content of 99%, can not be strengthened by heat treatment; low strength, but has good ductility, formability, weldability and corrosion resistance; anodic oxidation can improve corrosion resistance, and beautiful surface;Scope of application: mainly produces sheet metal and strip. Suitable for making all kinds of deep stamping products, and is widely used in various fields from cooking utensils to industrial equipment.

- Q:25mm thickness of hard aluminum processing to 6mm how to process, thank you all

- Oh, the 25mm thickness of the hard aluminum processing to 6mm, I suggest you contact the mill for rolling it.

- Q:Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Aluminum has a resistivity of 2.65 x 10^-8. But I will use your figure of 2.82 x 10^-8. R = ρL/A where ρ = resistivity = 2.82 10-8 Ω · m, L = Length = 28 meters, A = Area =( .58mm/2)^2 x pi = 0.26 mm^2, or 2.6 x 10^-7 m^2 R= (2.82 x 10^-8)(28)/2.6 x 10^-7 = 3.03 ohms I=V/R = 9/3.03 = 2.97 amps

- Q:Can aluminum sheets be used for food packaging?

- Indeed, aluminum sheets possess the potential to serve as food packaging. Owing to its distinctive qualities, aluminum emerges as a favored material for food packaging. Its attributes include being lightweight, flexible, and possessing exceptional barrier properties, enabling it to safeguard food products effectively from moisture, light, oxygen, and other external impurities. Aluminum sheets frequently find application in packaging diverse food items, including beverages, canned goods, ready-to-eat meals, and snacks. Moreover, aluminum is recyclable, rendering it an environmentally conscious preference for food packaging.

- Q:Can 101 aluminum sheets be welded?

- Yes, 101 aluminum sheets can be welded. Aluminum, including 101 aluminum alloy, is commonly used in welding due to its excellent weldability. It is important to note that proper welding techniques and equipment should be used to ensure a successful weld.

- Q:How do you clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, follow these steps: 1. Start by wiping the surface of the aluminum sheet with a soft cloth or sponge to remove any loose dirt or debris. Avoid using abrasive materials that can scratch the surface. 2. For regular cleaning, mix a mild detergent or dish soap with warm water in a bucket or sink. Dip the cloth or sponge into the soapy water and gently scrub the aluminum sheet, applying light pressure in circular motions. Be sure to clean both sides of the sheet. 3. Rinse the sheet thoroughly with clean water to remove any soap residue. It's important to remove all traces of detergent as it can leave behind a film or residue. 4. For stubborn stains or grime, you can use a non-abrasive cleaner specifically designed for aluminum surfaces. Apply the cleaner to a cloth or sponge and scrub the affected areas. Rinse with clean water afterward. 5. After cleaning, dry the aluminum sheet thoroughly with a clean, soft cloth to prevent water spots or streaks. It's important to dry it completely to avoid any moisture that can lead to corrosion or oxidation. 6. To maintain the aluminum sheet's shine and protect it from future damage, you can apply a thin layer of aluminum polish or wax using a clean cloth. This will create a protective barrier and enhance the sheet's appearance. 7. Regularly inspect the aluminum sheet for any signs of damage, such as scratches or dents. If you notice any issues, take appropriate steps to repair or replace the sheet to prevent further damage. By following these steps, you can effectively clean and maintain aluminum sheets, ensuring their longevity and preserving their appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Sheet AA3003 for ACP Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords