Coated Metal Aluminium Alloy Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

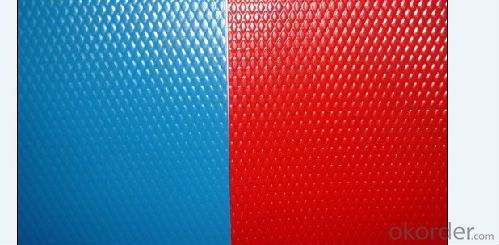

We can offer various kinds of coated aluminum sheets:

- Standard Alloy: 1100, 1050. And 3003, 3005, 3105 and etc. could be accepted too.

- Standard width: 1240mm, 1270mm. And it is accepted from 120mm to 1590mm

- Thickness: 0.10mm to 0.60mm

- Coating thickness: polyester coating>= 17 micron. pvdf coating >= 25 mircon.

- Hardness (pencil hardness) more than 2H

- Adhesion: 5B (EN ISO-2409: 1994)

- Impact resistance :No cracking and peeling(A.S.T.M D2794-1993)

- MEK resistance more than 100

- Color : there are 30 stardard colors according to our color chart. And you color is accepted if you could post us a sample.

- Shippment: 15 days for standard width & standard alloy. If specials, delivery time need to be confirmed order by order.

Applications:

Used to manufacture decorative material, such as aluminium composite panel, brushed panel, lampshade, and other composite panels.

1) Exterior applications such as: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

2) Interior applications such as: wall cladding, ceilings, bathrooms, kitchens and balconies

3) Advertisement and market applications such as: display platforms, signboards, fascias and shop fronts

4) Transport and industry applications

FAQ

Price term: Ex-Work,FOB,CNF,CFR,DDP,DDU,or as required

Payment term:TT,L/C,Western Union,by cash,or as required

Delivery Time: Prompt delivery,or based on the quantity of order.

- Q:How are aluminum sheets tested for quality and compliance with industry standards?

- Aluminum sheets are tested for quality and compliance with industry standards through various methods such as visual inspection, dimensional measurements, mechanical tests, and chemical analysis. Visual inspection involves checking for surface defects, scratches, and discoloration. Dimensional measurements ensure that the sheets meet the required thickness, width, and length specifications. Mechanical tests assess the strength, hardness, and ductility of the aluminum sheets through techniques like tensile testing and impact testing. Chemical analysis involves determining the chemical composition and purity of the sheets, ensuring they meet the required standards. Overall, these comprehensive testing methods ensure that aluminum sheets adhere to industry quality standards.

- Q:which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q:My understanding of the periodic table, the transitional metals all rust because the S shells are higher energy then the D shells. So all transitional metals have 2 valence electrons. (Roughly...some electrons like to move around and give different apparent charges.) So why does aluminum corrode if it doesn't have a 2+ charge?

- 'Rusting' commonly refers to the corrosion (oxidation) of iron so when talking about other metals, it is better to use the term 'corrosion' or 'oxidation'. Aluminum can corrode and the fact that it has a general oxidation number of +3 doesn't really matter. Many elements which have a charge that is different from +2 can oxidize. Alkali metals for instance (which have a charge of +1) can oxidize. Lithium can form lithium oxide (Li2O), sodium can form sodium oxide (Na2O) and so on. However, aluminum is known to be quite resistant to corrosion (oxidation) because it spontaneously forms a thin (solid) oxide layer at it's surface protecting it from further oxidation whereas iron, for an example, will easily lose that thin layer (it ''peels off easily'') exposing more iron to corrosion. So since Al has a +3 charge and O has a -2 charge, you'll need 2 atoms of Al and 3 atoms of O to make an electrically neutral compound. 2 atoms of Al = +6 charge 3 atoms of O = -6 charge Hence Al2O3 which is aluminum oxide. I hope it helps.

- Q:What are the different types of alloys used for painted aluminum sheets?

- There are several different types of alloys that are commonly used for painted aluminum sheets. One of the most popular alloys is 3003, which is known for its excellent corrosion resistance and high formability. This alloy is often used for applications where a smooth surface finish is desired, such as in the automotive industry. Another commonly used alloy is 5052, which offers a higher strength compared to 3003. This alloy is often used in marine and architectural applications due to its excellent corrosion resistance and ability to withstand harsh environments. It is also known for its good weldability and formability. Additionally, 6061 is a popular alloy choice for painted aluminum sheets. This alloy is known for its high strength and excellent machinability. It is often used in structural applications, such as in the manufacturing of aircraft parts and automotive components. Other alloys that are sometimes used for painted aluminum sheets include 2024, 5754, and 7075. These alloys offer specific properties that make them suitable for certain applications, such as high strength or improved corrosion resistance. Overall, the choice of alloy for painted aluminum sheets depends on the specific requirements of the application, such as the desired strength, corrosion resistance, and formability.

- Q:How do I choose the right thickness for my aluminum sheet?

- When choosing the right thickness for your aluminum sheet, there are several factors you should consider. Firstly, you need to determine the specific application or purpose for which you will be using the aluminum sheet. Different projects may require different thicknesses based on the structural or aesthetic requirements. For instance, if you are using aluminum sheets for roofing or siding, a thicker gauge might be necessary to provide sufficient durability and resistance to weather conditions. Secondly, you should consider the level of strength and rigidity required. Thicker aluminum sheets generally offer greater strength and stability, which is crucial for applications such as construction or automotive components. However, keep in mind that thicker sheets may also be heavier and more difficult to work with, so consider the practicality and weight limitations of your project. Additionally, it is important to think about the size of the aluminum sheet you need. Larger sheets may require thicker gauges to maintain their structural integrity, while smaller sheets may not need as much thickness. Lastly, consider your budget. Thicker aluminum sheets can be more expensive due to the increased material cost and manufacturing process. Strike a balance between the required thickness and your budget constraints to ensure you make a cost-effective decision. In summary, choosing the right thickness for your aluminum sheet involves considering the specific application, required strength, size, and budget. It is recommended to consult with industry experts or suppliers who can provide guidance and advice based on your specific needs.

- Q:Are aluminum sheets suitable for electrical applications?

- Yes, aluminum sheets are suitable for electrical applications. Aluminum has excellent electrical conductivity, making it a popular choice for various electrical components and wiring. It is lightweight, corrosion-resistant, and can efficiently dissipate heat, making it appropriate for electrical applications where these properties are desired.

- Q:Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. Aluminum sheets should be stored in a clean and dry area to prevent any moisture absorption or corrosion. They should be kept in a well-ventilated space to avoid the buildup of any potentially harmful gases. It is important to stack the sheets properly, with adequate support and spacing, to prevent any bending or deformation. Additionally, aluminum sheets should be protected from direct sunlight to avoid any discoloration or fading. It is recommended to cover them with a suitable material, such as a plastic sheet or tarp, to provide an extra layer of protection. Proper storage conditions will help maintain the quality and integrity of the aluminum sheets for their intended use.

- Q:Can aluminum sheets be used as heat shields?

- Aluminum sheets are capable of being used as heat shields. The reason for this is that aluminum possesses exceptional thermal conductivity, enabling it to effectively conduct and transfer heat away from its source. Moreover, aluminum exhibits a high melting point, which enables it to endure high temperatures without distorting or warping. These characteristics render aluminum sheets an optimal selection for heat shield purposes, which encompass safeguarding delicate components and structures from heat-related harm in various industries such as automotive, aerospace, and industrial sectors. Additionally, aluminum is lightweight and comparatively easy to mold, which makes it a practical alternative for heat shields that necessitate installation in confined areas or intricate designs. In summary, utilizing aluminum sheets as heat shields provides efficient thermal protection while offering durability, versatility, and cost-effectiveness.

- Q:For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- This exact question, word for word, was asked and answered 7 months ago. See my source for the answer. And find something better to do than reposting old questions.

- Q:25mm thickness of hard aluminum processing to 6mm how to process, thank you all

- For a subject, use a saw. Can produce several, milling too wasteful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Metal Aluminium Alloy Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords