CMAX Series Strong Crusher For Small Size Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

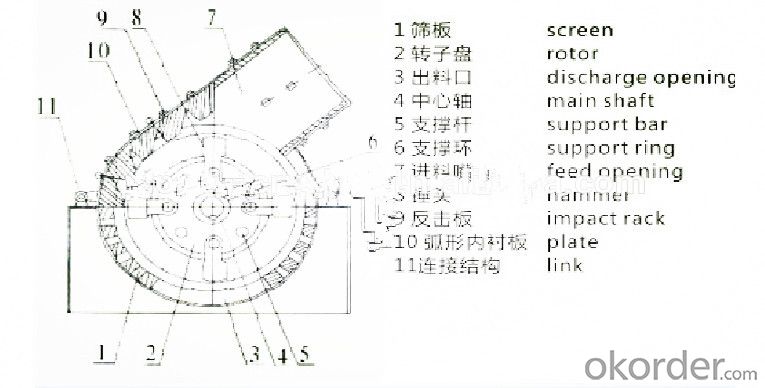

product show

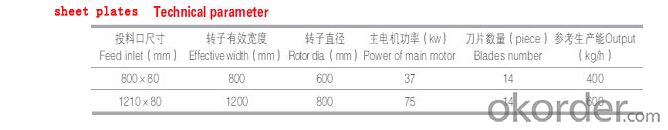

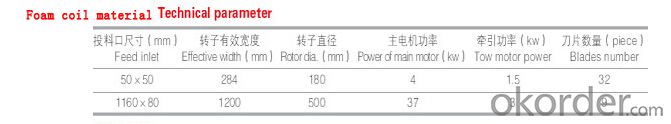

technical data

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:Plastic crusher does not eat what is the reason?

- Film, oiler, head of fast feed..... What type of crusher is used?...

- Q:Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- The crusher needs different structures for crushing different materials, especially the structure of the guide roller and the broken silo, which has little relation with the screen. If you really want to improve, then you need a certain amount of technology to achieve, do not damage the original function, but also increase its utilization rate, it is recommended that professional operations staff can be transformed.

- Q:How do you make plastics into particles?

- Then, the plastic granule is obtained by heating, melting and granulating through the plastic extruder.

- Q:Maintenance essentials of 300 kW generator rental system for recycled plastics machines

- 5, time of tool change, the gap between the knife and the fixed knife: above 20HP crusher crusher 0.5MM 0.8MM is better, better than 20HP. The thinner the recovery material, the gap can be properly adjusted. 6, second times before the start, should first remove the machine room remaining debris, to reduce the starting resistance. The inertia cover and the belt wheel cover shall be regularly opened to remove the ash discharge at the bottom of the flange plate, and the powder discharged from the plastic crusher chamber enters the shaft bearing. 7. The machine should be kept in good condition. 8, regular inspection of plastic crusher belt is loose, timely adjustment.

- Q:Is the waste plastics crusher harmful to the environment when it is produced?

- Low carbon, energy saving, low noise, tearing materials, recycling, and so on.It's the latest plastic shredder machine:

- Q:PVC what's the best blade for plastic crushers?

- 65Mn the most common, cheap, very sharp, the drawback is not wear-resistant. Grinds the blade original, feels that gives the minute Oh!

- Q:What material should be used for the plastic crusher screen?

- A plastic crusher is a high speed rotating cutting and crushing plastic, which is different from a rock crusher with a hammer head.

- Q:What does the crusher crush add to the weight of the crushing material?

- In fact, glass fiber reinforced plastic can also be regarded as a kind of plastic, although it is better than ordinary plastic strength, to be resistant, after all, it contains a lot of resin. If you want to break to about a centimeter, you can use Reed's single shaft crusher, lower production, but less investment. If you want to break to more than two centimeters, and the output is large, it is recommended to use Sred powerful biaxial crusher. The two machines are free of dust and low noise.

- Q:How much does it cost to run a disposable plastic basket factory?

- Do you want to have the first plastic basket according to the size of a certain area of the hydropower plant, complete; second have more than 1000 grams of plastic injection molding machine, plastic crusher and other equipment; the third to have the corresponding plastic mold products, this is not a small sum of money

- Q:What's the price of used plastic crushers?

- Like Shanghai Donglong good what. Good performance and high output. We do machine maintenance in our factory

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Series Strong Crusher For Small Size Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords