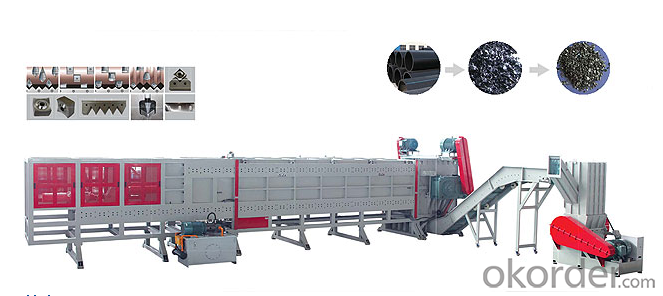

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard wooden case as usual |

| Delivery Detail: | Within 15 days after receipt of the deposit |

plastic pipe recycled bottle shredder unit

XIECHENG 30HP/22KW Crusher for Plastic Industry

1. Suitable for recycle of plastic casing, thin tube plastics, injection and mould sector, bottle plastics and shell plastics;

2. cmax series are easy to operate and simple to replace cutters. Spacious flat blade is suitable to granulate bulky and thin plastics, increases efficiency; installed with electrical safety devices; double wall hopper with sound-proof material. Motor is equipped with overload protector, and power protection devices. Safety and environmental protection, low electricity consumption and durable. Stainless steel hopper for all models is available.

plastic pipe crusher,large diameter plastic pipe crusher,plastic pipe crusher shredder machine

product show

Technical parameter:

Model | Feed dia.(MM) | Rotor blade swing diameter(MM) | rotor speed | Drive power | Max shredable pipe | Mechanical pusher power | OUTPUT(KG/H) |

CMAX-630 | 750*790 | 848 | 39 | 2*30 | 630 | 11 | 800-1000 |

CMAX-800 | 950*950 | 1028 | 33 | 2*37 | 800 | 11 | 1000-1200 |

CMAX-1000 | 1140*1160 | 1258 | 27 | 2*45 | 1000 | 15 | 1200-1500 |

CMAX-1200 | 1340*1360 | 1478 | 23 | 2*55 | 1200 | 15 | 1500-2000 |

- Q:Classification of equipment for plastics mills

- Plastic crusher in the injection molding industry, also known as: plastic crusher. There are three main categories:(1) hard plastic crusher, this machine is suitable for crushing all kinds of small and medium plastic sheets:1, ABS, PE, PP board and other plates crushed recovery;2. The rectangular feeding port designed for the crushing of plate materials is convenient for crushing long strip plates and improves work efficiency. The utility model can be matched with a suction fan and a storage barrel to form a plate crushing and recovering system, and the recycling efficiency can be more fully utilized;3, the use of sealed bearings, bearing rotation for a long time to maintain good; knife design is reasonable, the product even granules; knife stand heat shrinkable treatment, shape design beautiful and generous;

- Q:How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- The same kind of waste plastics can be broken and cleaned by plastic crusher, and then heated, melted and extruded by plastic extruder

- Q:600 of the plastic crusher, there are 18 pieces of moving blades, 4 fixed blade, want to ask the blade and the fixed blade of the gap is how much?Look, the machine seems to have become smaller from left to right. Is that so?

- Plastic crusher, blade gap and broken materials, such as hard plastic gap can be larger, such as 0.5~1 mm, but the gap between the soft plastic as small as possible to prevent winding axis.

- Q:What are the differences between plastic crushers and particle machines, as well as the amount of money needed to buy machines and running capital? How much do I have to do to make it work? Yes, there are machines to buy machines, washing machines and crushers, and so on. Is everything a set? How much is the set? I'll do that. I'll go to the manufacturer and find the Department in it. And how do I ask him if he accepts my plastic?

- Compress and extrude and make plastic granules of mung bean size for easy use. Manufacturing of recycled plastic particles must have plastic crusher and plastic granulator, equipment according to advanced level and quality requirements, the price varies greatly,

- Q:How do you make plastics into particles?

- The heater needs to be heated first and then broken with a shredding knife.

- Q:PVC what's the best blade for plastic crushers?

- 9CrSi material is moderate in price, but it has a certain brittleness. It has to be used with little attention;

- Q:What does the crusher crush add to the weight of the crushing material?

- Crushing materials are generally sold to plastic factories, and HDPE materials are mainly used to make pots, barrels, turnover boxes, plastic pipes, hollow products, etc.. If you want to increase the added value of the broken material, it is better to break the material into pellets, which requires a plastic granulator (you can buy simple equipment, which is cheaper).

- Q:Working video of aluminium crusher

- The aluminum is not high enough, the crusher needs to consider separating from other metal, no video can't be delivered here. It needs the equipment to call me!

- Q:What kind of material is used for plastic hairpin?

- With plastic injection molding, just buy plastic injection molding machines and plastic crushers

- Q:How much does it cost to run a disposable plastic basket factory?

- Fourth that's the raw material, like the black plastic basket. The main ingredients of this kind of product are Recycled HDPE and polypropylene. Estimated equipment and die investment is about three hundred thousand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords