CMAX High -temprature-resistant Flexitank

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

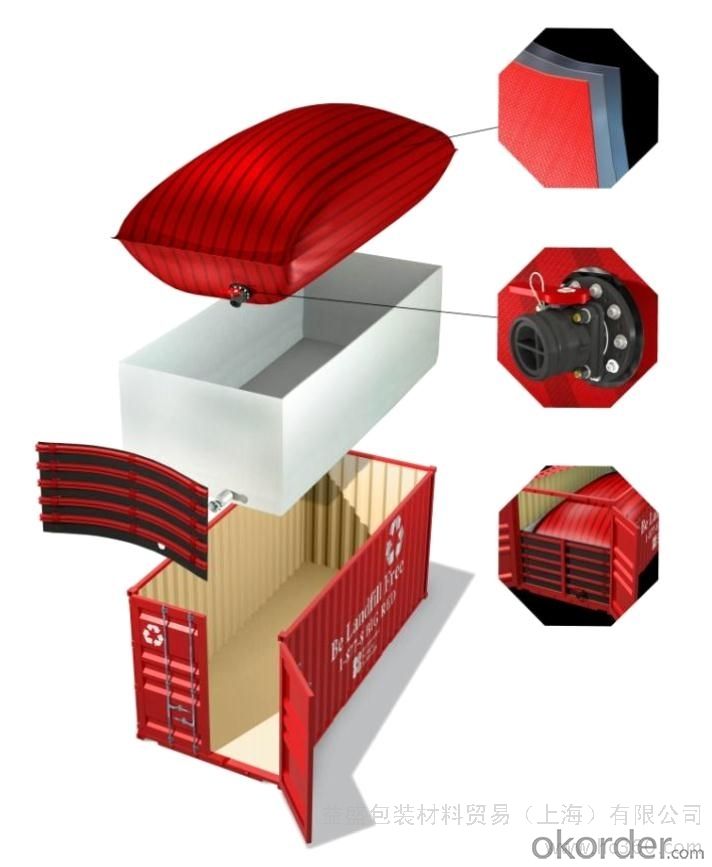

1、CMAX High -temprature-resistant Flexitank Product Description:

High -temprature-resistant Flexitank is a flexitank with CMAX new heat-resistant material technology, is specially designed bulk liquid cargo with high filling temperature like liquid bitumen/asphalt; it is suitable for all kinds of liquid road bitumen, liquid chemicals with high filling temperature.

2、Features and Benefits:

uCompared with general-purpose flexitank, CMAX high-temprature-resistant lexitank could withstand 60-90℃ filling temprature, high pressure resistant,strong and durable.

uLoad 30% more than with drums per 20ft container

uSave 50%+ package positioning cost than with drums per 20ft container

uThe inner bag could be melted into bitumen, no damage to bitumen quality, environment friendly and convenient for operation.

3、Application:

Suitable for all kinds of liquid road bitumen,chemicals with high filling temperature.

4、Features and Benefits:

u More convenient, simple, and economical compared to the conventional tank packaging

u Foldable with strong impermeability, no leakage, anticorrosive, and cleaning-cost saving

u Increase loading capacity, shorten transport time, and improve the efficiency of transport

- Q:Which container is a good container?

- This question, each person's answer is not the same, the liquid suppliers on the market countless, each location is not the same, mainly depends on customer demand. You decide the price is the most important, the low price is good; you decide the quality of the product is the most important? Or service quality is the most important? Or choose brand reputation better? Everyone's needs are different, and the choices are different.

- Q:How is the container liquid bag unloading process carried out?

- Ensure normal safety, can have a great effect platform. The fifth is unloading process, such as a lot of residue, can choose liquid bags, drag and other auxiliary action until the goods discharged. Make sure all container liquid bags are managed effectively and clean and convenient. Sixth is about the goods after unloading, closed valves, and valve cover, to avoid pollution. Ensure the safety management performance of the environment. Finally, close the container car and the right door. Carry out inspection and management of container liquid bags and give us a good environment for effective improvement.

- Q:On the problem of unloading container liquid bags

- Container tilting machines are used to tilt the container

- Q:What kind of general chemicals can be packed in container bags?

- Food categoryWine, edible oil, concentrated juice, food additives, sorbitol, palm oil, soy sauce, Yellow Wine, mineral water, malt extract, syrup, etc.

- Q:Brief introduction of container liquid bag

- Compared to the traditional tank, the liquid bag can carry more goods and can load more than 40% of the original container, so the number of containers needed can be reduced, thus saving the capital.(3) BULKHEAD can be installed in the liquid bag, equal to a heat sink, and its maximum temperature is 80 degrees. This liquid, which has a temperature requirement, is very good. It can heat up these special liquids. This is a traditional pot can not do.(4) the operation of the liquid bag is very simple. It takes only a few people and a few tubes to complete the operation, while the traditional IBC and the tank require dozens of workers to put the things in order. Second, its handling is also very simple. The liquid can be loaded from the top valve through the pipe and then released from the bottom valve through the pipe when it is released.(5) besides the benefits of cost savings mentioned above, the biggest advantage of liquid bags is that they are inexpensive. The price is nearly half that of the traditional method. Leakage: very responsible to say, liquid bag soft packaging material, leakage inevitable. Is also the biggest obstacle to the use of liquid bags. There are many reasons for leakage, which are divided into: liquid bag design defects; liquid bag production quality defects; improper use (including foreign bodies, scratches, fierce collisions, etc.).What can be done now is to improve design, strictly monitor quality, and strengthen customer guidance, thereby reducing the risk of leakage. Through rapid network response, reasonable insurance claims can further cover possible risks.Strengthen customer guidance, rational use of liquid bags; at the same time to strengthen communication and transportation enterprises, reasonable operation of container fluid bags, thereby reducing the risk generated.

- Q:What brand of container liquid bag is good? How to lead the liquid bag?

- Qualification: through the China National entry-exit inspection and Quarantine Center Laboratory, according to the GB/T5009.60-2003 standard for testing, product hygiene to meet the GB9687-88 standard requirements, suitable for the export of food. The liquid bag meets the American FDA standard and can safely store and transport food grade goods;

- Q:What reason is the container loaded?

- There is stone goods, packing process, forklift drivers into the box, it is also easy to cause box wall drum

- Q:How can rubber oil be removed from container liquid containers?

- If the winter is too sticky, steam or steam the bottom of the load and pump it out

- Q:How can the corn cob packed in ton bags fit into the container and ship by sea?

- Empty containers do not unload, open half of the door, cut packets, and then use the conveyor belt to corn grain to the box, but the door needs a stack of bags wall, to avoid the overflow of corn.

- Q:Are container liquid bags expensive to produce? What machines are needed?

- The general liquid bag is made of 4 layers of PE film through heat sealing, but the sealing equipment and technology have to pass the customs and meet the requirement of bearing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX High -temprature-resistant Flexitank

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords