CMAX High -temprature-resistant Flexitank -HIGH QUALITY

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 70000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX offers safe, efficient, cost-effective bulk liquid logistics transportation service with CMAX flexitank, which is the most reliable and safe flexitank solution available; lowering your risk, costs and environmental impact.

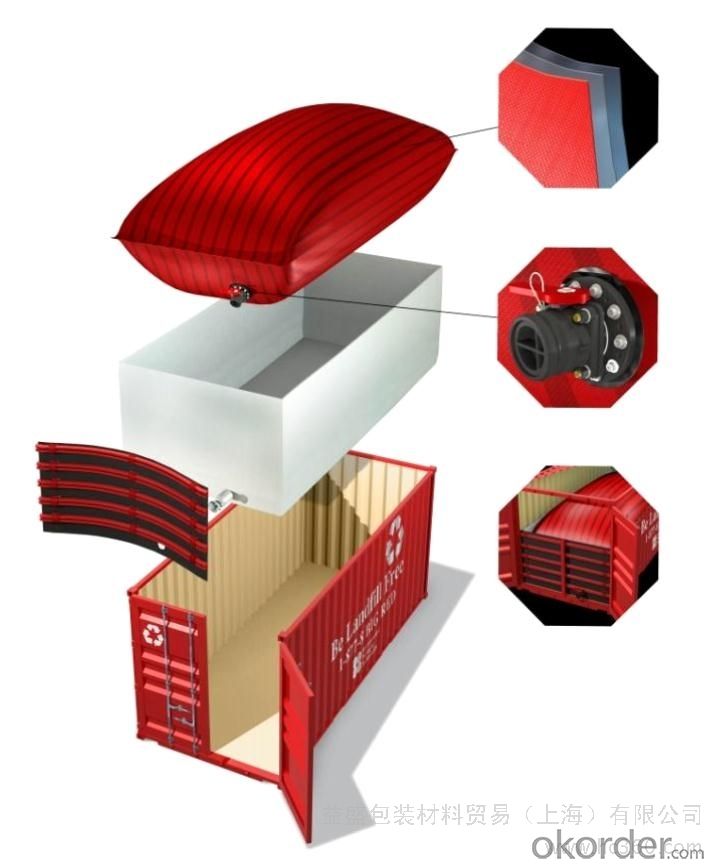

A CMAX flexitank transforms a standard 20’ ISO container into a non-hazardous bulk liquid transportation system. Designed specifically to ensure your bulk liquid cargo arrives safely and in optimum condition, CMAX flexitank incorporates the very latest barrier technology materials to protect your product from contamination during transit.

CMAX Flexitank System Features and Properties:

u Made from 100% clear virgin polyethylene materials. Fully compliant with FDA and EU Regulatory Food Contact regulations. Contains no carbon black.

2.Safe and Reliable

u Strengthen the inner bag with high-tensile purpose durable one-piece tubular polypropylene woven fabric that provides intensive protection to the liquid cargo loaded within the inner bag.

u Mechanical heavy steel constructed bulkhead system is designed for double protection to liquid cargo within the container, with which a container loaded with 24,000L liquid flexitank has been witnessed safely passed the COA Railway Impact Test done at AAR( TTCI). , in which the container received 2 times huge impacts at the running speed of 6mph.

u CMAX flexitank system is fully COA compliant in accordance with the latest edition of the COA Flexitank Code of Practice. All impact testing g was witnessed, verified and certificated by Lloyds Register.

u The specially designed cam lock male valve with anti-suction pad allows efficient discharging without human labor with small volume cargo residue.

4.24-hour Global Service

u Offer services including container preparation, flexitank fitting, cargo loading supervision, inland and maritime transportation, flexitank discharging, disposal and recycling via global network covering 5 continentals, 80 main ports via CMAX offices and 36 agents around the globe.

u 24-hour public service line offers instant communication and action upon request around the world.

5.Eco-environmental

u All polyethylene, polypropylene, steel materials used are fully recyclable, all are environmental friendly.

6.Cost-effective

u Compared to ISO Tank, no cleaning cost, no returning cost.

u Load 30% more than with drums per 20ft container

u Save 50%+ package positioning cost than with drums per 20ft container

- Q:What kind of general chemicals can be packed in container bags?

- The liquid bag than conventional tank, can carry more goods than the original container can be installed more than 40%, then the number of containers needed can be reduced, and can save money (3) liquid bag can be installed inside the BULK HEAD, is a thermal insulation device, the high temperature it is 80 degree. This liquid, which has a temperature requirement, is very good. It can heat up these special liquids. This is a traditional pot can not do.

- Q:How is the container liquid bag unloading process carried out?

- Ensure normal safety, can have a great effect platform. The fifth is unloading process, such as a lot of residue, can choose liquid bags, drag and other auxiliary action until the goods discharged. Make sure all container liquid bags are managed effectively and clean and convenient. Sixth is about the goods after unloading, closed valves, and valve cover, to avoid pollution. Ensure the safety management performance of the environment. Finally, close the container car and the right door. Carry out inspection and management of container liquid bags and give us a good environment for effective improvement.

- Q:Is it possible to export container liquid bags (cooking oil) as dangerous goods?

- It's easy to leak a leak, as soon as a touch of Mars or flammable material catches fireSo plastic packing is recommended!

- Q:What kind of general chemicals can be packed in container bags?

- Various types of fatLubricating oil, lubricating oil additives, transformer oil, white oil, tung oil, glycerin, coconut oil, hydraulic oil, industrial gear oil, castor oil, high oil fatty acid, oleic acid

- Q:What kind of containers do you have for transporting petrochemical products?

- It's just a special liquid bag. Check the container before loading. The liquid bags are placed inside the container

- Q:Is it really safe to change containers to liquid containers?

- Liquid bags should be packed first.

- Q:What's the maximum capacity for container liquid bags? What sizes do you have? Can chemical goods be loaded? Is the risk index high?

- Liquid bag general shipping company requires about 20 tons, because the liquid bag after loading, bag expansion, if installed 20 tons, it is easy to make box wall at both sides of the drum deformation.

- Q:What is the container fluid bag? Is it safe to use this liquid?

- (1) first of all, it is disposable. After use, it can be discarded. There is no extra room to store the liquid bags and clean it. It does not have any extra fees and so on. It can save a lot of money. In addition, the advantages of disposable use are sanitation and environmental protection. Every time they use a brand new liquid bag, it can avoid the pollution of the goods. (2) the liquid bag can carry more goods than the traditional tank, and it can be loaded more than 40% of the original container. Then the number of containers needed can be reduced, so that it can save the capital. (3) BULKHEAD can be installed in the liquid bag, equal to a heat sink, and its maximum temperature is 80 degrees. This liquid, which has a temperature requirement, is very good. It can heat up these special liquids. This is a traditional pot can not do. (4) the operation of the liquid bag is very simple. It takes only a few people and a few tubes to complete the operation, while the traditional IBC and the tank require dozens of workers to put the things in order. Second, its handling is also very simple. The liquid can be loaded from the top valve through the pipe and then released from the bottom valve through the pipe when it is released. (5) besides the benefits of cost savings mentioned above, the biggest advantage of liquid bags is that they are inexpensive. The price is nearly half that of the traditional method. Disadvantages of leakage: it is very responsibly to say that liquid bag soft packing material, leakage is inevitable. Is also the biggest obstacle to the use of liquid bags. There are many reasons for leakage, which are divided into: liquid bag design defects; liquid bag production quality defects; improper use (including foreign bodies, scratches, fierce collisions, etc.).

- Q:What reason is the container loaded?

- General cargo loading will appear this kind of circumstance, such as steel, if both sides of the wall without box wood pad, finished goods or packing process, it is easy to cause the box wall on both sides of the outer drum.

- Q:How can rubber oil be removed from container liquid containers?

- If the winter is too sticky, steam or steam the bottom of the load and pump it out

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX High -temprature-resistant Flexitank -HIGH QUALITY

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 70000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords