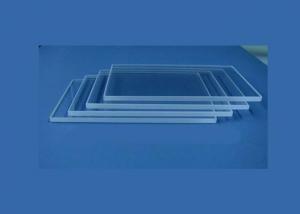

Clear Glass Ceramic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main colors: black, clear,white, dark red

Thickness: 3.8mm 4mm 4.5mm 5mm 6mm

max size 420*1500mm

Specifications of Clear Glass Ceramic

Transparent glass ceramic is made of uniformed crystallization and Lithia. The crystal nucleus can prevent expansion. It also provides chemical stability, resist impact damage, and it is transparent. Electronic glass-ceramic is used as faceplate or panel of various electronic furnaces.

Main colors: black, clear,white, dark red

Thickness: 3.8mm 4mm 4.5mm 5mm 6mm

max size 420*1500mm

temperature resistance >1000 °C

heat impacting >700 °C

Description of Clear Glass Ceramic

White glass ceramic low coefficient of heat expansion

Excellent shock resistance

Size can be customized

Do print

Quality Assurance of Clear Glass Ceramic

1. Density---approx. 2.56 g / cm3

2. Modulus of Elasticity--- approx. 93 x 103 Mpa 3, Bending Strength--- approx.

3. 6 MPa The bending strength testing is to be accomplished according to DIN EN 1288 part 5 (R45).

4. Thermal Characteristics Coefficient of Mean Linear Expansion---α(20 - 700oC) (0 ± 0.5) x 10-7 /K

5. Resistance to Temperature Differences (RTD) Resistance of the panel to temperature differences between heated zone and cold panel edge (room temperature). No cracking due to thermal stress at Tes, max1<=700 degree C

6. Thermal Shock Resistance Resistance of the panel to thermal shock when the hot panel (780 degree C) is quenched with cold water (20oC temperature). No cracking due to thermal stress at Tes, max<=700 degree C

7. Chemical Characteristics of Base Material Acid Resistance--- DIN 12116: at least class S3 Alkaline Resistance---based on ISO 695: at least class A2

8. Screen printing: complies with RoHS standards, normal ink available

9. Impact resistance: A steel ball (diameter 60mm, weight 188g) freefall from180mm height, striking the panel

10 times. No scratching or cracking.

- Q:Mobile phone film new flexible toughened glass membrane, really is the glass?

- Tempered glass (Temperedglass/Reinforcedglass) belongs to safety glass. Glass has a fairly good abrasion resistance and is very hard, with a Vivtorinox hardness of 622 to 701.

- Q:What is glass fiber reinforced nylon?

- With excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self extinguishing, good dimensional stability, widely used in automotive industry products, textile products, pump impeller and first class precision engineering componentsPA6 enhancement series:With good wear resistance, heat resistance, oil resistance and chemical resistance, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

- Q:What are the chemicals in glass?

- Common raw materials are quartz sand, feldspar, calcite, calcium carbonate, three, two aluminum oxide, sodium carbonate, borax and so on.

- Q:Not man-made destruction, why toughened glass suddenly broken?

- There are a variety of predisposing factors 2. tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q:Why is the process of glass toughened always broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q:How to identify and select high quality insulating glass?

- At present, there are three kinds of insulating glass in China: (1) groove aluminum type single channel sealing; (two) groove aluminum double channel sealing; (three) compound sealant strip type insulating glass. Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so the kind of insulating glass gradually eliminated.

- Q:Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic is English Acrylics, Acrylics is acrylic acid (ester) and methacrylic acid (ester) general class of chemicals. People often say that the acrylic sheet is polymethyl methacrylate (PMMA) plate, which is composed of methyl methacrylate monomer (MMA) polymerization.

- Q:What are the raw materials of water glass?

- The water soluble alkali metal silicate glass is formed by the combination of alkali metal oxide and silica, also called paohuajian. Water glass can be divided according to the type of alkali metal sodium silicate and potassium silicate, the molecular formula of N and K2O.nSiOz. in Na2O.nSiO2 coefficient is called the modulus of water glass, molecular oxidation silicon and alkali metal oxides in water glass ratio (or molar ratio). The modulus of water glass is an important parameter of water glass, generally between 1.5-3.5. The greater the modulus of water glass, solid water glass is difficult to dissolve in water, which can dissolve in water at room temperature for n 1, n is required to increase the water solubility. N is greater than 3 to 4 above atmospheric pressure steam can be dissolved. The modulus of water glass is larger, more silicon oxide content, water glass viscosity, easy decomposition hardening, bond strength increases.

- Q:What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q:What is the glass industry?

- The glass belongs to the chemical industry, glass production process mainly includes: raw material processed. The massive raw materials (quartz sand, soda ash, limestone, feldspar) grinding, wet material drying, iron containing raw materials for iron removal treatment, in order to ensure the quality of glass batch preparation. 2. The melting of glass batch. High temperature in the furnace or crucible kiln (1550~1600) heating, so as to form uniform, no bubbles, and meet the requirements of molding liquid glass.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China |

| Year Established | 2011 |

| Annual Output Value | |

| Main Markets | 8.33% North America 8.33% South America 8.33% Eastern Europe 8.33% Southeast Asia 8.33% Africa 8.33% Oceania 8.33% Mid East 8.33% Eastern Asia 8.33% Western Europe 8.33% Central America 8.33% Northern Europe 8.33% Southern Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | guangzhou |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Clear Glass Ceramic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords