China Factory Supplier High Alumina Refractory Cements CA50 CA70 CA80

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Alumina Cement |

| SiO2 Content (%): | <0.8-0.5 | Al2O3 Content (%): | 50-80 | CaO Content (%): | 20-35 |

| Refractoriness (Degree): | Super-Class (Refractoriness> 2000°) | Model Number: | CA50, CA70, CA80 | Brand Name: | CNBM |

| Raw Material: | Calcined Aluminum + Limestone | Compressive Strength, Mpa: | Min40 | Bending Strength, Mpa: | Min6 |

| Bulk Density, g/cm³: | Min2.3 | Setting Time: | Fast |

Packaging & Delivery

| Packaging Details: | 1.25kg bag piled or one ton bag on pallet/in case, wooden pallets with plastic film 2. Gross weight: 500-900kgs |

| Delivery Detail: | Around 20 days |

Quality Refractory

Technical: Advanced researching and developing center

Advantages: Quick-drying high speed; High performance of heat resistance; High efficiency of construction

Capacity: 500,000 metric tons per year

Applications: Castable, Firebricks, Furnaces, etc.

Parameters

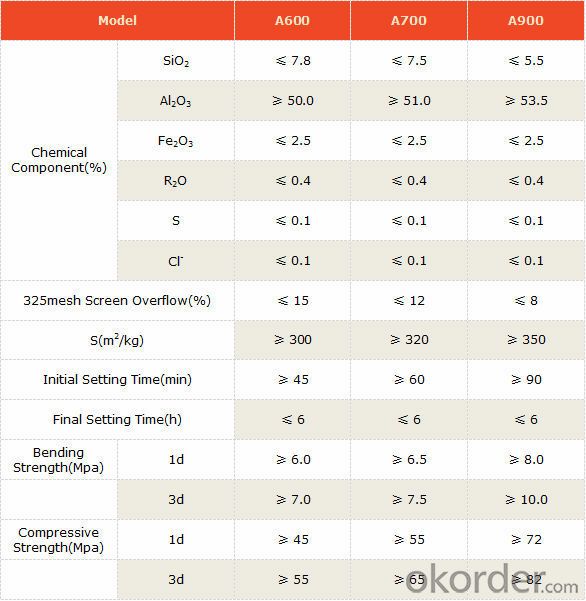

Refractory Cements CA-50

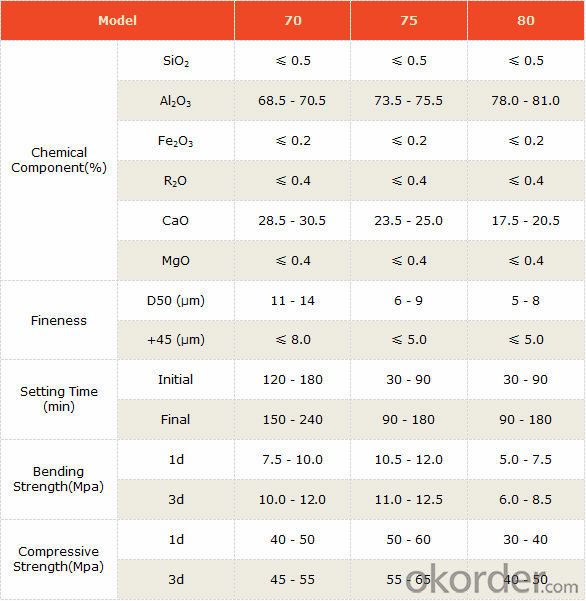

High Purity Refractory Cements CA-70 CA-75 CA-80

More Pictures

Our Service

Our Belief for Customer Service

We hold this belief all the time: We always provide our customers with high quality and competitive products, which can reduce their cost and increase their profit. We will try our best to achieve win-win cooperation and enhance the quality of people’s life together.

- Q:Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Why is the apple screen so small?

- Q:Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q:What refractory material does cupola lining use?

- In order to improve the service life of the lower wall and the bottom leather, dense and high alumina brick can be used for masonry. The front furnace is composed of the bottom, the wall and the top. The top of the furnace is vaulted or hanging flat roof. The front furnace body is usually made of clay brick and high alumina brick, and the bottom work floor is rammed with ramming material. The material is the same as that of cupola furnace. The bridge and the front guard taphole, slag hole and other parts due to erosion by high temperature molten iron and slag erosion, lower service life, frequent repairs. Large blast furnace adopts hot blast or oxygen enriched blast, which has higher temperature and higher production capacity... The damage is faster, and it is hard to maintain production by using clay brick or high alumina brick. Should be used aluminum, carbon or corundum refractory silicon carbide castables pouring or tamping, so that the integrity of good, high strength, corrosion resistance, and therefore significantly improved service life, generally up to one year or so. Refractory materials, including chimneys and spark traps, are used in other parts of the cupola. The chimney and the cupola shaft directly connected with the shell made of steel plate, lined with ordinary clay brick, can also be used ordinary refractory castable pouring. The chimney is provided with a furnace heat exchanger, which can preheat the air to 300~500 DEG C, and the spark collector is used for catching the hot coke and dust particles brought out in the flue gas. The chimney at the top of the reflector (cover) by plate welding, can also be used to cast iron, its lining refractory coating or spraying paint.

- Q:What are the insulation fireproofing materials?

- Asbestos is the most common. Asbestos containing zirconium and made of the mixture of zirconium aluminum and silicon through wire drawing is better. Of course, some are made directly from natural things which can withstand 1400 degrees for over 30 seconds while the internal temperature had no significant change, and withstand 1400 degrees for over five minutes while inside temperature increase does not exceed 5 degrees.

- Q:Which brand of AAA refractory is good?

- Rong Sheng Kerui quality refractory Zhengyuan Shenzhou Saatchi these brands are very good, with high refractoriness, durability and with a good cost performance. Get the majority of customers' recognition.

- Q:Who knows the refractoriness of high temperature lightweight firebricks?

- The disadvantage of light refractory bricks is its poor thermal insulating ability and the advantage is its endurable heat resistance property. The temperature range and main features of thermal insulation refractory are as follows. Diatomite brick

- Q:How to make fire resistant materials for building stoves

- Legend of the old version has been upgraded, or can not enter the server, is not legend stopped?

- Q:Which region use more refractory?

- Gongyi of Henan province use more refractories

- Q:Could you tell me the fire-resisting time of class B fire proof door?

- Could you tell me the fire-resisting time of class B fire proof door?

- Q:What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Hello there. Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. As for the warehouse building "category malonate", it refers to one of the fire risk of goods storage, which is divided into A, B, C, D, E, and each category is refined depending on the nature of different substances. "Malonate class" specified in article 3.1.3 of "building design for fire protection" refers to the flammable solid.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China Factory Supplier High Alumina Refractory Cements CA50 CA70 CA80

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords