Chemical Index of Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Chemical Index of Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Chemical Index of Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Chemical Index of Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

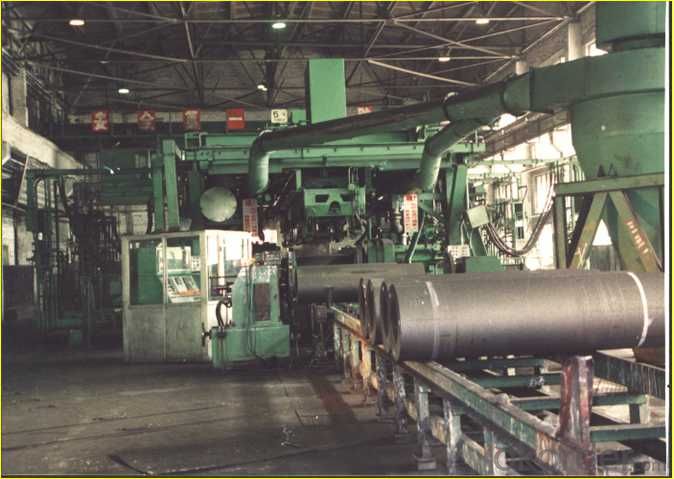

Image

Chemical Index of Graphite Electrodes UHP with Nipples

FAQ:

Chemical Index of Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

Applications

Chemical Index of Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q:Why should graphite paper be placed between the heater and the graphite electrode?

- . Different single crystal furnace heaters may be of the same size or may be different. The heater is determined according to the size of the Czochralski single crystal furnace and the parameters of the drawn single crystal, and is generally designed in the form of a parallel circuit, and the following parameters. A heater, the heater, the shape of two inner diameters of three, four, the effective length of the heater heater, the heater piece is five thickness and gives the heater diameter. These parameters are determined according to Czochralski single-crystal furnace parameters and its crystal diameter. The power transformer parameters are mainly based on the single crystal furnace heating power: maximum output power, maximum output voltage and maximum output current, diameter and height of the crucible. The design of the heater has the following steps: 1. Selecting and determining the shape of the heater; the heater is made of high purity graphite; the resistivity of the high purity graphite; the heater is usually made into a cylinder at present.

- Q:After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- Negative poleThe color becomes lighter (the copper ion gets electrons in the cathode and becomes copper)

- Q:Is graphite electrode good for foreign trade?

- Foreign sales commission depends on the price you talk to the customer, and the profit is objective.

- Q:What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q:Why use platinum ferroalloy instead of iron as electrode?

- General industrial grade silicon dioxide, because the preparation technology is different, can be divided into two types, one is dry, sintered (Fume Type), a wet precipitation type (Precipitated Type), and two of the surface area, the surface with hydroxyl (-OH) are the same, in general, the former the latter is more, less, the two surface has the tendency of hydrophilic, as for lipophilic polymer, such as paint, rubber... Etc.,... If the silica surface pre rendered hydrophobic, has a good effect.

- Q:The use of graphite as an electrode in alumina electrolysis

- The technical knowledge of electrolytic aluminum, cleaning and maintenance of alumina equipment, you can search for Baidu on the green, looking for.

- Q:Graphite electrode press device

- Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q:What are the factors affecting the service life of graphite electrode in ultra high power arc furnace?

- China's graphite electrode quality standard (YB/T4090-2000) to evaluate the quality of the ultra high power graphite electrode is defined 6 physicochemical indexes, including resistivity, flexural strength, elastic modulus, bulk density and linear expansion coefficient as the quality evaluation index, ash as a reference index.

- Q:How does graphite produce solar cells?

- The team at the Massachusetts Institute of Technology has confirmed that electrodes based on graphene and ITO devices are comparable in efficiency. Although the power conversion efficiency of graphene is 4.2% lower than that of a general silicon cell, it will be competitive for special use in the future.

- Q:800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chemical Index of Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords