Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

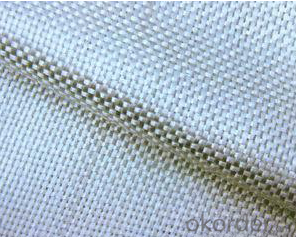

Weave:Plain,Twill,Satin,Multiaxial,UD

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:How do fiberglass fabrics perform in terms of UV resistance?

- Fiberglass fabrics have excellent UV resistance properties. The composition of fiberglass, which is made from fine fibers of glass, allows it to withstand prolonged exposure to ultraviolet (UV) radiation without significant degradation. Unlike many other fabrics, fiberglass does not easily deteriorate or become brittle when exposed to sunlight. The glass fibers in fiberglass fabrics are inherently resistant to UV rays due to their inorganic nature. This means that they do not contain any organic compounds that can be broken down or degraded by UV radiation. As a result, fiberglass fabrics can maintain their strength and integrity even after prolonged exposure to sunlight. In addition to their natural UV resistance, fiberglass fabrics can be further enhanced by the addition of special coatings or treatments. These coatings can provide additional protection against UV rays, increasing the fabric's longevity and ability to withstand outdoor conditions. Overall, fiberglass fabrics are known for their exceptional UV resistance. They are commonly used in applications where exposure to sunlight is a concern, such as outdoor furniture, marine applications, and automotive components. Their ability to withstand UV radiation makes them a durable and reliable choice for various industries and environments.

- Q:How does fiberglass fabric perform in static dissipation?

- Fiberglass fabric is typically not designed to function as a material that dissipates static. The reason for this is that fiberglass acts as an insulator, preventing the flow of electricity. Static dissipation involves the safe dispersal of static electricity to prevent harm or dangers. To achieve effective static dissipation, materials must possess conductive properties. Nevertheless, there exist specific types of fiberglass fabrics that have been developed with conductive properties to enable static dissipation. These fabrics are generally coated or infused with conductive substances such as carbon fibers or metals. The conductive additives within these fabrics facilitate the creation of a pathway for static electricity to move through, thus allowing for safe dissipation. It is important to acknowledge that the effectiveness of fiberglass fabric in static dissipation can fluctuate depending on the particular composition and construction of the fabric. Moreover, factors such as humidity levels, surface conditions, and the presence of other materials or objects in the surroundings can also impact the efficacy of static dissipation. Consequently, it is advisable to consult the manufacturer's specifications or conduct testing to ascertain the static dissipation capabilities of a specific fiberglass fabric.

- Q:How does fiberglass fabric compare to other fabric materials in terms of cost?

- Fiberglass fabric tends to be more expensive compared to other fabric materials.

- Q:Can fiberglass fabrics be used for reinforcement in sporting goods?

- Yes, fiberglass fabrics can be used for reinforcement in sporting goods. Fiberglass is known for its strength and durability, making it an ideal material for reinforcing various sporting equipment such as surfboards, kayaks, skis, and hockey sticks. The lightweight nature of fiberglass also allows for increased maneuverability and performance in these sporting goods. Moreover, fiberglass fabrics can be easily molded into different shapes and sizes, ensuring a perfect fit for the specific sporting equipment being reinforced. Overall, fiberglass fabrics offer excellent reinforcement properties, making them a popular choice in the manufacturing of sporting goods.

- Q:How does fiberglass fabric perform in abrasive environments?

- Fiberglass fabric is known for its exceptional performance in abrasive environments. Its unique composition and construction make it highly resistant to wear and tear caused by abrasion. Firstly, fiberglass fabric is made from fine strands of glass fibers that are woven together to create a strong and durable material. These glass fibers possess excellent resistance to abrasion, making the fabric highly resilient and capable of withstanding the repetitive rubbing or scraping actions often encountered in abrasive environments. Additionally, fiberglass fabric is commonly coated with a protective layer or finish to further enhance its resistance to abrasion. This coating acts as a barrier, preventing the abrasive particles from directly coming into contact with the fabric. As a result, the fabric is able to maintain its integrity and performance over time, even in extremely abrasive conditions. Moreover, fiberglass fabric exhibits low friction properties, which is beneficial in abrasive environments. This low friction characteristic reduces the chances of the fabric being abraded or worn down due to constant rubbing or contact with rough surfaces. It also helps to minimize the generation of heat, which is often associated with abrasion, thereby contributing to the fabric's longevity and performance. Overall, fiberglass fabric is an excellent choice for applications in abrasive environments. Its inherent resistance to abrasion, coupled with protective coatings and low friction properties, ensures that the fabric can withstand the challenges posed by abrasive conditions, providing long-lasting performance and durability.

- Q:Can fiberglass fabric be used for making sports jerseys?

- Yes, fiberglass fabric can be used for making sports jerseys. It is a strong and durable material that offers excellent resistance to wear and tear. However, it may not be commonly used for sports jerseys due to its lack of breathability and potential discomfort for athletes.

- Q:Can fiberglass fabrics be used for insulation in buildings?

- Indeed, insulation in buildings can be achieved using fiberglass fabrics. These fabrics consist of delicate glass fibers intricately woven together, and they are widely utilized as a means of thermal insulation. Their ability to minimize heat transfer is remarkable, allowing for a cozy atmosphere during chilly winters and a cool environment during scorching summers. Furthermore, fiberglass fabrics possess a lightweight nature, making installation effortless, and their exceptional resistance to fire makes them a highly sought-after option for insulation in various types of structures, be it residential, commercial, or industrial.

- Q:How is fiberglass fabric used in the marine industry?

- Fiberglass fabric is extensively used in the marine industry due to its unique properties and versatility. It is primarily used for boat building and repair, offering exceptional strength, durability, and corrosion resistance. In boat building, fiberglass fabric is used to create the hull, deck, and other structural components of the boat. It is typically combined with resin, forming a composite material that is lightweight yet incredibly strong. The fabric is laid in layers, impregnated with resin, and then cured to form a rigid and robust structure. One of the key advantages of fiberglass fabric is its ability to withstand the harsh marine environment. It is highly resistant to water, chemicals, and UV radiation, making it ideal for boats that are constantly exposed to saltwater and sunlight. This resistance significantly reduces the maintenance and repair costs associated with marine vessels. Fiberglass fabric is also used in the repair and restoration of boats. It can be applied to damaged areas, providing structural reinforcement and restoring the integrity of the vessel. The fabric can be easily molded and shaped to fit the specific contours of the boat, ensuring a seamless repair. Additionally, fiberglass fabric is used for the production of marine accessories and equipment. It is commonly used to manufacture boat seats, storage compartments, and panels due to its lightweight nature and ability to resist moisture and corrosion. Overall, fiberglass fabric is a crucial material in the marine industry. Its strength, durability, and resistance to the marine environment make it an ideal choice for boat construction, repair, and various marine applications.

- Q:What are fiberglass fabrics made of?

- Fiberglass fabrics are made of thin strands of glass, typically composed of silica, which are woven together to form a flexible and durable material.

- Q:Can fiberglass fabric be used for making sports equipment?

- Yes, fiberglass fabric can be used for making sports equipment. It is a lightweight, durable, and flexible material that is commonly used in the production of various sports equipment such as kayaks, surfboards, hockey sticks, and bicycle frames.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords