Calcium Silicate Board for Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

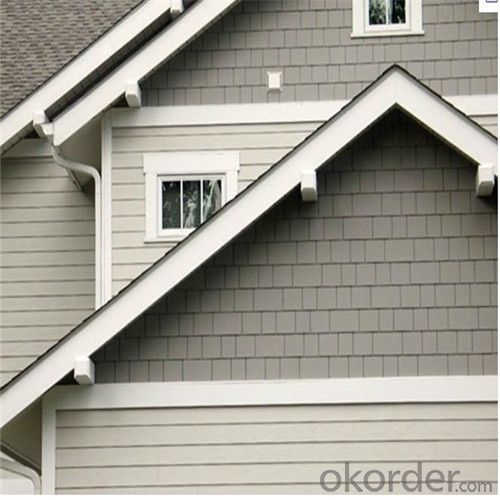

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages of high strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Specifications

non asbestos calcium silicate board

1)Outstanding Fire Resistance

2)Efficient Thermal Resistatant

3.5 --- 12 mm wall partition ceiling decoration calcium silicate board

Specification | Size | 2440*1220mm; |

Thickness | 4.5 to 12mm | |

Surface treatment | With or without sanded surface; bevelled | |

Custom Specifications available on request | edges available | |

Outstanding characteristics | Environmental friendly, 100% asbestos-free or 3%containing, outstanding fire resistance, high tensile and bending strength, remarkable moisture resistance, stable dimension, durable, excellent heat insulation and soundproofing, easy Installation | |

Main usage | Partitioning wall, ceiling tile | |

Other usage | Protecting wall system, movable floor, countertop, panel | |

billboard, kitchen and bathroom wall, | ||

pipeline insulation | ||

Physical property | Raw material | Tobermorite, cement, Quartz sand, fiber |

Density | 1.1-1.3 g/cm3 | |

Flexural strength | >13 Mpa; real test >15 Mpa (GB/T7019-1997) | |

Moisture content | <10%< span=""> | |

Fire rating test | Class A incombustible material (GB8624) | |

Soundproofing | 45-55 dB (GBJ75-84) | |

Thermal conductivity | ≤0.3W/MK (JC/T564) | |

Radiation | Accordance with standard (GB6566-2001) | |

Incombustibility | 4 h | |

Moisture movement | ≤0.25% (GB/T7019-1997) | |

Dry shrinking rate | <0.09%(GB/T7019-1997) | |

Application | Commercial, industrial, and apartment buildings

| |

Application:

partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Moisture:<10%< span="">

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:i'm replacing the tiles in my tub area and i'm changing the existing wall to cement board. how do i join it with the rest of the bathroom wall that's texture?

- find the studs to screw into and use liquid nails

- Q:Fiber reinforced silicate board which is good

- Pumai explosion-proof pressure relief board by the vent fiber, perlite light aggregate through a special process into a new type of lightweight, vent fire, easy to build a new type of pressure relief plate.

- Q:Performance of fiber cement pressure plate

- 1, fire insulation: non-flammable A1 level, does not produce toxic gases; low conductivity 2, waterproof and moisture: not afraid of water, not afraid of wet, more suitable for bathroom, swimming pool, underground passage and so on. 3, anti-corrosion pest control: high corrosion resistance, no rust, not afraid of mosquito bites bite

- Q:What is water and water? How to do it?

- More and more architects in the world use clean water technology, such as world-class architects Beixing Ming, Ando Tadao and so on in their design a lot of use of water concrete. Sydney, such as the hospital, the National Theater of Japan, the prehistoric museum in Paris and other world-renowned art class construction, are using this architectural art.

- Q:Lightweight composite wallboard can not be attached to the wall

- Light composite wall panels, is for modern high-rise buildings, ecological residential interior space, size and structure, and the development and production of solid light wall panels, due to its unique performance characteristics, the market also known as "light composite wall panels "," Light wall panels "," solid wall panels "," composite wall panels "," strip wall panels "and other names, hereinafter referred to as lightweight composite wall panels.

- Q:Hi All,Basically what I am trying to say is that I have a wooden board which will be placed vertically on the floor and would be a decoration.I want to have a coating of cement of some sort on it and make some patterns on it.I like to know if it is possible to lay a thin coating layer of cement or even tile bond glue to a wooden board, lets say a timber board.basically anything that can give me the concrete/cement look as rough as that.. uld be any kind of cement or tiling glue or such...Thanks

- It might crack on you so why don't you just use some modeling clay and use a trowel and just play with it to look like cement

- Q:Or only where the ceramic tile floor will be installed. Should the pan just sit on the 5/8 wood subfloor?

- Definitely use the cement board. 5/8 Plywood is really crappy subfloor. It just has too much give. The minimum should be 3/4 and 1 1/8 is ideal for a floor that won't dip, sag or cause tile to crack.

- Q:Can you put ceramic tile over wood floors? If yes I was told that it wouldnt stay, even with cement board.?

- Without reading any answers here, and after installing thousands of sq. ft. of flooring,,,especially tile. I suggest that EVEN on a concrete slab,,, perfection isn't something set in stone,,, so to speak. You don't state the state of the construction,,, IE: Basement or crawl space below the existing floor, slab on dirt, etc.. ANY floor substrate should be as level as you can get it,,, but even that can be supplemented by leveling a tile installation. Concrete backer board is my choice, no matter the substrate, as it allows for less movement, degradation over time, a porous/textured enough surface to GRAB thin set, with less chance for warp,,, as long as the bottom line is as secure as possible. Perhaps your least or greatest concern might be removing any existing base molding and determining adding what might be near 3/4 inch height to existing flooring. Consider a deeper issue. This is EARTH, on top of which,,, or in which a house has been built. I suggest no stronger force exists than that of the EARTH.... and it gives and takes, in its process. Consider too, the prep work, and knowledge of the structure, its construction, and history. Does it tend to ebb and flow like Tides? Or has its base element been relatively secure since it was constructed? Then consider that it may last longer, no matter what you do, or what was done, than your lifetime,,, No offense. It would seem that research is your first exploration option, and valid experience. If in fact the base flooring is above a basement or crawl space some shimming might be called for, especially if the existing floor seems to squeak, or be pliant. If it's Concrete, I suggest you don't stress. E mail accepted for more info. Rev. Steven

- Q:What is the difference between cement calcium silicate board and cement fiberboard

- Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, through the pulp, copy, pressure, curing from a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board. Fiber cement board length and width of the standard specifications are 1200 * 2400mm and 1220 * 2440mm, manufacturers can basically customize the length of 2000-2500mm, width of 1000-1250mm within any specifications, other specifications can be cut on this basis. Fiber cement cement board thickness of 2.5,3,3.5,4,5,6,8,9,10,12,15,18,20,24,25,30,40,60,90 mm, the strength of the manufacturers Can be customized within any thickness of 2.5-100mm. Thickness of 4mm or less known as ultra-thin plate, 4-12mm become a conventional plate, 15-30mm and above known as thick plate, 30mm or more known as the thick plate. No small press manufacturers can only produce 6-12mm ordinary cement board; general manufacturers can only produce 4-12mm conventional board, thick plate to do well, thick plate can not do; thickness 2.5-100mm can do the manufacturers The country is small. Cement fiber board is widely used, the sheet can be used for ceiling materials, perforation can be used as sound-absorbing ceiling. Conventional board can be used for wall and / or decorative materials, thick plate can be used as LOFT steel floor board, attic board, external wall insulation board, wall panels and so on.

- Q:Can cement fiber board be attached to fire board?

- Can be affixed, with Porsche stickers, completely no problem. I am glue factory manufacturers, if you need the right glue

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board for Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords