Calcined Anthracite Coal Carbon Coke for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

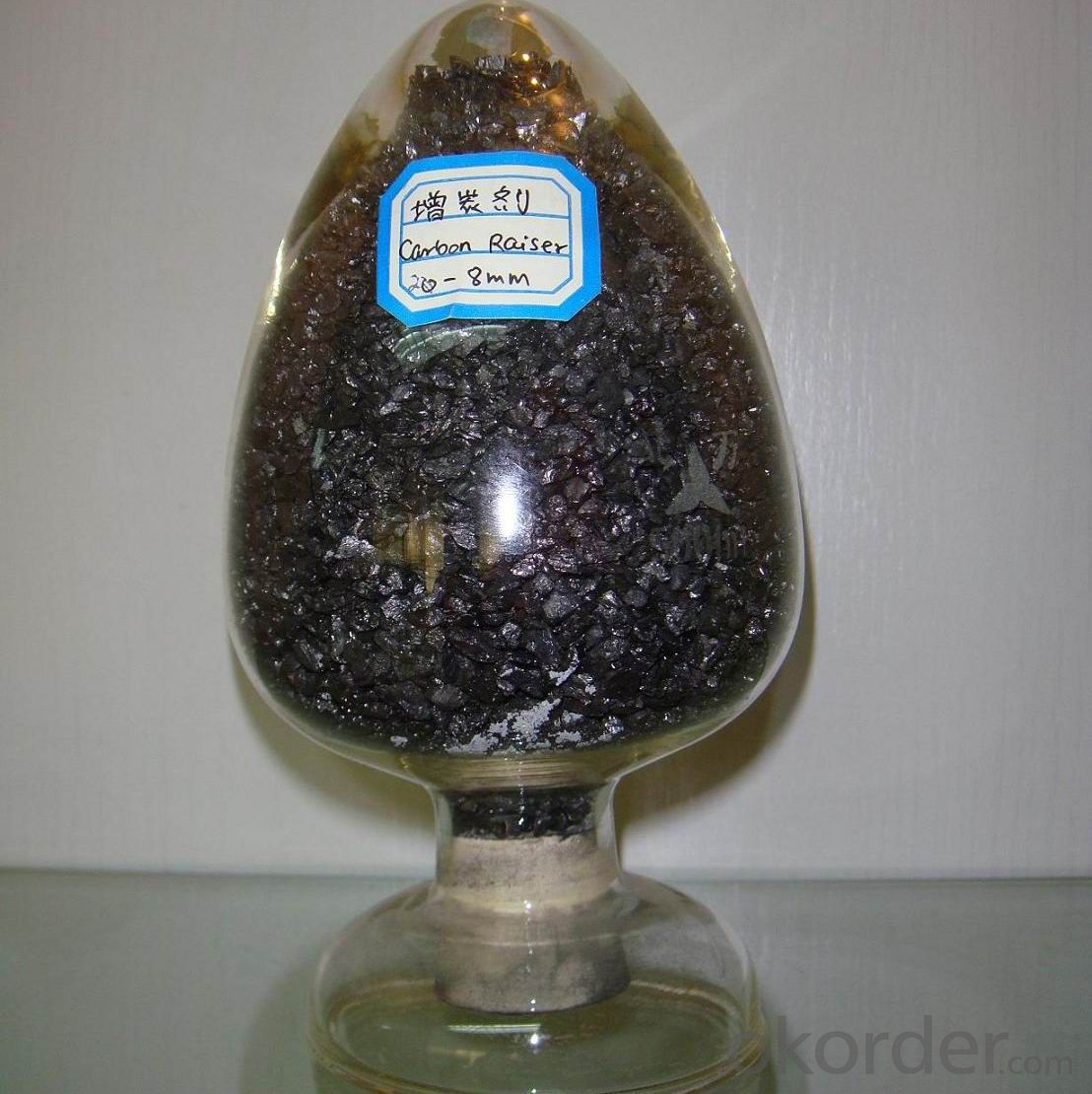

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

Packaging Details: | In 1MT plastic woven bag. |

Delivery Detail: | 30-40 DAYS |

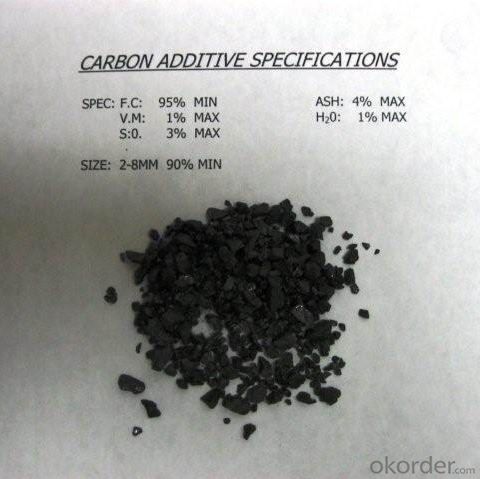

Calcined Anthracite Coal Carbon Coke for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Features of Calcined Anthracite Coal Carbon Coke for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

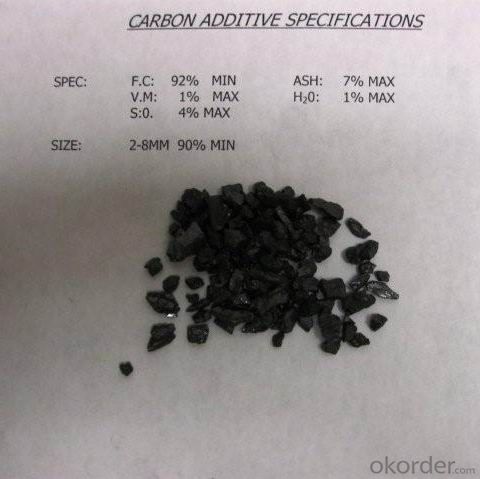

Specifications of Calcined Anthracite Coal Carbon Coke for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

FAQ of Calcined Anthracite Coal Carbon Coke for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is:instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage of Calcined Anthracite Coal Carbon Coke for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

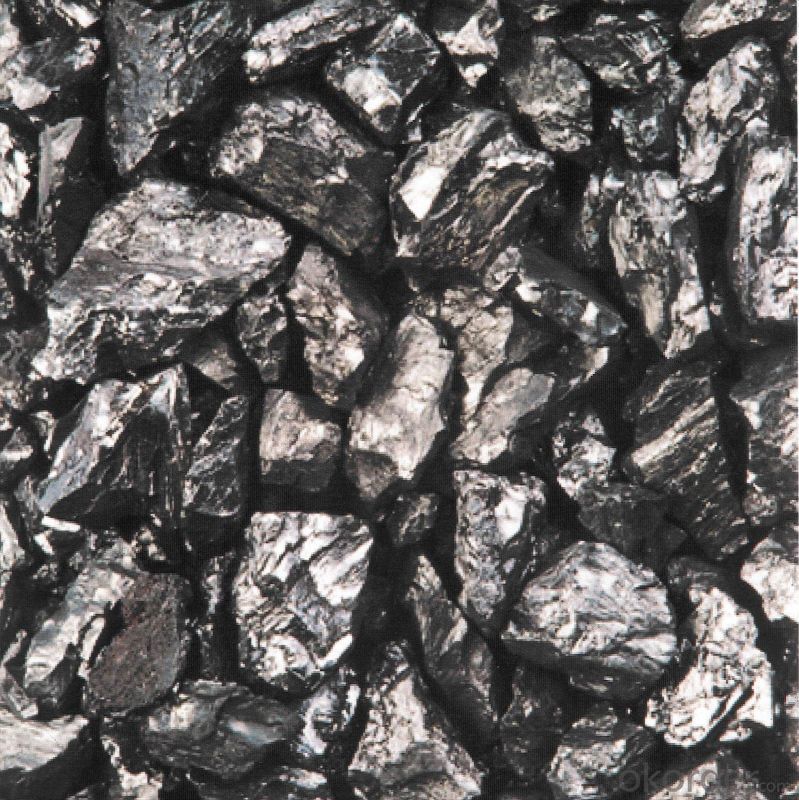

Images of Calcined Anthracite Coal Carbon Coke for Steelmaking

- Q:How does carbon affect the formation of tsunamis?

- Carbon does not directly affect the formation of tsunamis. Tsunamis are primarily caused by underwater earthquakes, volcanic eruptions, or landslides. Carbon, in the form of carbon dioxide (CO2), is a greenhouse gas that contributes to global warming and climate change. While carbon emissions and the resulting climate change can impact ocean temperatures and sea levels, they do not directly trigger the formation of tsunamis. However, it is important to note that climate change can indirectly influence the intensity and frequency of natural disasters, including tsunamis, through its impact on oceanic and atmospheric conditions. Rising sea levels caused by melting glaciers and polar ice can potentially increase the destructive power of tsunamis by allowing them to reach further inland. Additionally, climate change can affect the frequency and magnitude of earthquakes and volcanic activity, which are the primary triggers of tsunamis. Therefore, while carbon emissions do not directly affect tsunami formation, their impact on climate change can indirectly influence the factors that contribute to the occurrence and severity of tsunamis.

- Q:How is carbon used in the production of diamonds?

- Carbon is used in the production of diamonds through a process called high-pressure high-temperature (HPHT) synthesis. In this method, pure carbon is subjected to extremely high pressures and temperatures, replicating the conditions found deep within the Earth's mantle where natural diamonds form. By applying these conditions, carbon atoms rearrange and bond together, resulting in the formation of synthetic diamonds.

- Q:When will amines be fertilized?

- Carbon is the most commonly used varieties of amine fertilizer, with nitrogen and phosphorus fertilizer, fertilizer use, fertilizer is generally 120 days or so, the suitable conditions of temperature, moisture in the next 50 days after applying fertilizer best.Carbon amine is a white compound that is granular, plate-like or columnar crystalline. Because ammonium bicarbonate is a carbonate, it must not be placed with acids because the acid reacts with ammonium bicarbonate to form carbon dioxide, which causes ammonium carbonate to go bad. However, in the rural areas, ammonium carbonate and acid reaction are also used. The ammonium bicarbonate is placed in the vegetable greenhouse, and the greenhouse is sealed, and ammonium bicarbonate is placed at the top, adding hydrochloric acid. At this point, the amines react with hydrochloric acid to produce ammonium chloride, water, and carbon dioxide. Carbon dioxide can promote plant photosynthesis, increase vegetable production, and the resulting ammonium chloride can also be used as fertilizer again. Ammonium bicarbonate in the chemical formula of ammonium ion, is an ammonium salt, and ammonium salt and alkali can not be put together, so ammonium bicarbonate and sodium hydroxide or calcium hydroxide should not be put together

- Q:How is carbon used in the production of solar cells?

- Carbon is not directly used in the production of solar cells. Solar cells are typically made of semiconductor materials like silicon or cadmium telluride. However, carbon-based materials can play a crucial role in enhancing the performance and efficiency of solar cells. One way carbon is used is in the form of carbon nanotubes, which can be used as a transparent electrode in solar cells. Carbon nanotubes have excellent electrical conductivity and optical transparency, making them an ideal candidate for replacing traditional transparent conductive materials like indium tin oxide. Additionally, carbon-based materials can be used as a coating or encapsulation layer, providing protection to the solar cells from moisture, corrosion, and mechanical stress. Carbon-based materials also have the potential to be used in the development of next-generation solar cell technologies, such as organic solar cells or perovskite solar cells, which utilize carbon-based compounds in their active layers. Overall, while carbon may not be directly used in the production of solar cells, it plays a crucial role in improving their performance and enabling the development of more advanced solar cell technologies.

- Q:The difference between double offset paper and carbon free printing paper

- In general, we use office A4, A3, B5 and other specifications of office paper are better offset paper, excellent offset paper to UPM and APP for the domestic leader.55G-140G grams in general, some mills also produce high grams, generally belongs to industrial paper!Carbon free copy is just typing paper and coating. Paint is divided into two kinds, one kind of colored, one kind of colorless.Generally for 37G, 45G, 52G and other grams.

- Q:What are the advantages of carbon-based batteries?

- Carbon-based batteries, such as alkaline batteries, have become a popular choice in various applications due to their numerous advantages. Firstly, their longer shelf life sets them apart from other battery types. They have the ability to retain their charge for extended periods, making them particularly suitable for devices that are infrequently used or for emergency situations. In addition, carbon-based batteries offer a higher energy density, enabling them to store more energy in a compact package. This makes them lightweight and convenient for portable electronic devices like smartphones, laptops, and cameras. Moreover, these batteries have a lower self-discharge rate, meaning they lose less charge over time when not in use. As a result, they can maintain their power for longer periods without the need for frequent recharging or replacement. Furthermore, carbon-based batteries possess a higher discharge rate, allowing them to deliver power quickly when required. This is especially advantageous for devices that demand a sudden burst of energy or for high-drain applications like digital cameras or power tools. Another notable advantage of carbon-based batteries is their cost-effectiveness. They are readily available, inexpensive to produce, and can be easily recycled, thereby reducing their environmental impact. In conclusion, carbon-based batteries offer a range of benefits, including a longer shelf life, higher energy density, lower self-discharge rate, higher discharge rate, cost-effectiveness, and environmental friendliness. These features make them a reliable and efficient choice for a wide array of electronic devices and applications.

- Q:Power plant water treatment plant, there is a carbon removal device, the expert pointing out what the principle is it?

- The water enters from the upper part of the carbon removing device and is poured down by the water distribution equipment and enters the water tank from the lower part through the filling layer. In addition to carbon, due to the blocking effect of filler, flow down from the top of the water is dispersed into many small stocks or drop, from the bottom of the drum into the air and water contact area is very large, and the partial pressure of carbon dioxide in the air is very low, so it will come out from the water desorption carbon dioxide quickly away. Water can be removed by blowing carbon, which can reduce the carbon dioxide content to below 5mg/L. In fact, the simple point is that the amount of dissolved gas in water is proportional to the pressure of the air he touches. This principle is similar to the principle of the atmospheric Deaerator in the power plant. I hope I can help you

- Q:What are the impacts of carbon emissions on coral reefs?

- Carbon emissions have significant impacts on coral reefs. One of the most significant consequences is the process of ocean acidification, caused by the absorption of excess carbon dioxide (CO2) from the atmosphere. As the ocean becomes more acidic, coral reefs struggle to build and maintain their calcium carbonate skeletons, essential for their structure and survival. This can lead to reduced growth rates and weakened reefs, making them more susceptible to damage from storms, disease, and other stressors. Additionally, the rising ocean temperatures resulting from carbon emissions have led to widespread coral bleaching events. When corals experience prolonged exposure to high temperatures, they expel the symbiotic algae (zooxanthellae) living within their tissues, which provide them with essential nutrients and give them their vibrant colors. Without these algae, corals become pale or completely white, a phenomenon known as bleaching. If the stressors subside, corals can recover, but if the bleaching is severe or prolonged, it can lead to coral death and the subsequent degradation of the reef ecosystem. Furthermore, increased carbon emissions contribute to the intensification of storms and other extreme weather events, which pose a direct threat to coral reefs. Stronger storms can physically damage the reefs, breaking apart their fragile structures and reducing their resilience. The resulting sediment runoff from land, often exacerbated by storms, can smother corals and hinder their ability to feed and grow. The impacts of carbon emissions on coral reefs are not only detrimental to these diverse marine ecosystems but also to the millions of people who depend on them for food, income, and coastal protection. Coral reefs support a vast array of marine life, provide a source of livelihood for many communities through fishing and tourism, and act as natural barriers against storm surge and coastal erosion. The degradation of coral reefs due to carbon emissions threatens the livelihoods and well-being of these communities, as well as the overall health and biodiversity of our oceans. To mitigate these impacts, it is essential to reduce carbon emissions by transitioning to cleaner, renewable energy sources, promoting sustainable practices on land to reduce runoff and pollution, and implementing effective management and conservation measures to protect and restore coral reef ecosystems.

- Q:What is a carbon electrode? What's the use? What's the current situation in the industry? Try to be specific. Thank you

- 2, application:Compared with other carbon products, carbon electrode has the characteristics of wide application field, and can be used in the smelting furnace of industrial silicon, yellow phosphorus, calcium carbide, ferroalloy and so on. Carbon electrodes have been used all over the mine furnace in developed countries.At present, in the smelting furnace of industrial silicon and yellow phosphorus, the graphite electrode with higher price has been replaced. In the submerged arc furnace of the same capacity, compared with graphite electrode, carbon electrode diameter can be made larger (now the domestic production of carbon electrode, Phi 650- Phi 1200mm graphite electrode at home can do with 600mm) in the furnace, arc zone broadening, arc stability, ensure the hot efficiency, increase the output of products, reduce the power consumption of products.

- Q:What is the greenhouse effect?

- The greenhouse effect refers to the process by which certain gases in the Earth's atmosphere trap heat from the sun and prevent it from escaping back into space. This natural phenomenon is crucial for maintaining the planet's temperature within a range suitable for life. However, human activities, such as burning fossil fuels and deforestation, have intensified the greenhouse effect, leading to global warming and climate change.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Anthracite Coal Carbon Coke for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords