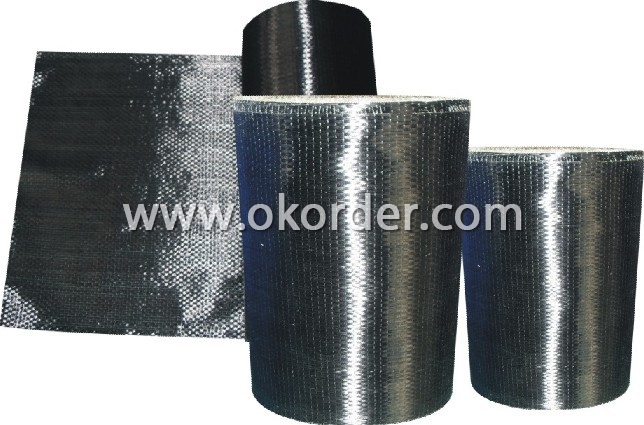

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Fiber Tape:

Temperature: less than 550 degree C;

Width: 10mm to 150mm, on customers request;

Thickness: 1.5mm to 6.0mm, as your requirements.Carbon fiber tape is woven by carbon fiber, used as insulation materials and an excellent substitute for asbestos tape. High adhesive, resistant to abrasion and moisture, economical, high tensile strength, long storage.

Application of Carbon Fiber Tape:

Industrial thermal insulation, piping and electrical cable lining, shielding against heat radiation, high temperature oven door curtain, flange jointing with bolts, friction reinforcement materials, etc.

General Data of Carbon Fiber T400

Weaving Style: Unidirectional, Plain, Twill

Input Available: 3k, 6k, 12k Carbon fiber

Weight: 15 0 ~ 600g / m2

Roll length: To be specified

Storage of Carbon Fiber Tape

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber Tape

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

- Q:How does carbon impact the structure and function of ecosystems?

- Carbon, as a fundamental element, plays a crucial role in shaping the structure and function of ecosystems. It serves as a building block of life, found in all living organisms, and continuously cycles between the atmosphere, living organisms, and the Earth's surface. The impact of carbon on ecosystems is diverse, both directly and indirectly. To begin with, carbon is a vital component of organic matter, including plants, animals, and decomposing organic materials. It provides the necessary energy and nutrients for the growth and development of organisms. Through the process of photosynthesis, plants absorb carbon dioxide from the atmosphere and convert it into organic compounds, primarily carbohydrates. These compounds serve as a source of energy and building materials for other organisms, forming the basis of the food chain. As a result, carbon is essential for sustaining the productivity and biodiversity of organisms within ecosystems, as it contributes to their structure and functioning. Additionally, carbon influences the physical structure of ecosystems. In terrestrial ecosystems, carbon is stored in vegetation and soils, creating carbon sinks. Forests, for example, store significant amounts of carbon in their biomass and soils. This plays a crucial role in mitigating climate change by absorbing and sequestering carbon dioxide. However, the loss of these ecosystems, due to deforestation or degradation, can release large amounts of carbon back into the atmosphere. This contributes to the greenhouse effect and climate change. In marine ecosystems, carbon is stored in the form of dissolved inorganic carbon, which can affect ocean acidity. The increasing concentration of carbon dioxide in the atmosphere leads to ocean acidification, impacting the growth and survival of marine organisms, particularly those with calcium carbonate shells or skeletons, such as corals and mollusks. Furthermore, carbon influences the functioning of ecosystems through its role in nutrient cycling. Decomposition, the process of breaking down and recycling organic matter, is largely driven by microorganisms that respire carbon dioxide. This process releases essential nutrients, such as nitrogen, phosphorus, and sulfur, back into the soil, making them available for uptake by plants. Nutrient cycling is crucial for maintaining the productivity and nutrient balance within ecosystems. Changes in the availability of carbon can affect the rates of decomposition and nutrient cycling, which, in turn, impact the structure and functioning of ecosystems. In conclusion, carbon is a fundamental element that significantly impacts the structure and function of ecosystems. Its involvement in energy transfer, organic matter formation, nutrient cycling, and climate regulation makes it essential for the sustainability and functioning of all living organisms within an ecosystem. To ensure the health and resilience of ecosystems in the face of environmental changes, understanding and managing carbon dynamics is crucial.

- Q:How is carbon used in the production of construction materials?

- Carbon is used in the production of construction materials in several ways. One of the most common applications is in the production of steel, which is a vital material in the construction industry. Carbon is a key component in the iron and steel-making process, as it is combined with iron to create a stronger and more durable material. The addition of carbon to iron forms a compound known as steel, which has excellent structural properties and can be used to construct various components of buildings, such as beams, columns, and reinforcement bars. Additionally, carbon fibers are increasingly being used in the production of construction materials. Carbon fibers are lightweight, yet incredibly strong and stiff, making them ideal for reinforcing concrete and other materials. When carbon fibers are added to concrete, they enhance its strength and durability by reducing cracking and improving its resistance to impact and corrosion. This allows for the construction of structures that are more resilient and longer-lasting. Furthermore, carbon is used in the production of composite materials, which are becoming popular in construction. Carbon composites are made by combining carbon fibers with a polymer matrix, resulting in a material that is lightweight, yet strong and rigid. These composites are used in various construction applications, such as building panels, roofing, and bridges, as they offer high strength-to-weight ratios and excellent resistance to environmental factors. In summary, carbon plays a crucial role in the production of construction materials. It is used in the creation of steel, which is a fundamental component of buildings, and its fibers are employed to reinforce concrete and other materials. Additionally, carbon composites provide lightweight and high-strength solutions for construction applications. By harnessing the properties of carbon, construction materials can be made stronger, more durable, and more sustainable.

- Q:How does carbon impact the prevalence of avalanches?

- Carbon does not directly impact the prevalence of avalanches. The occurrence of avalanches is mainly influenced by factors such as snow conditions, slope steepness, and weather patterns. However, carbon emissions and climate change can indirectly contribute to increased avalanche risks by influencing snowpack stability and altering weather patterns, which can lead to more frequent and severe avalanches.

- Q:How is carbon used in the production of ink?

- Various forms of carbon, such as carbon black or activated carbon, are employed in the production of ink. Carbon black, a fine black powder derived from incomplete petroleum combustion, is commonly used as a pigment to achieve deep black color in inks. Its small size and high surface area enable even dispersion in the ink, ensuring consistent color. On the other hand, activated carbon is a porous carbon form produced by heating materials like wood or coconut shells at high temperatures. In ink production, it functions as a filter or purification agent. With its extensive surface area and microscopic pores, activated carbon effectively adsorbs contaminants and impurities from the ink, enhancing its quality and stability for a smooth flow. In addition to its purification role, carbon also serves as a conductive material in ink production. Carbon-based inks, widely utilized in applications requiring electrical conductivity such as printed circuit boards, sensors, or electronic devices, consist of dispersed carbon particles in a liquid medium. This allows them to be printed or deposited onto a substrate, creating conductive pathways. Overall, carbon's vital role in ink production encompasses providing color, acting as a purification agent, and enabling electrical conductivity. Its adaptable properties and vast range of applications establish it as an indispensable component in the ink manufacturing process.

- Q:What are the potential uses of carbon nanomaterials in medicine?

- Carbon nanomaterials have shown great promise in the field of medicine due to their unique properties. One potential use of carbon nanomaterials is in drug delivery systems. Their high surface area-to-volume ratio allows for efficient loading and release of therapeutic agents, enabling targeted and controlled drug delivery. This could lead to more effective treatments with reduced side effects. Another potential use is in medical imaging. Carbon nanomaterials, such as carbon nanotubes and graphene, have excellent optical and electrical properties that can enhance imaging techniques like MRI and CT scans. This could improve the accuracy and resolution of medical imaging, enabling better diagnosis and monitoring of diseases. Carbon nanomaterials also have antibacterial properties which can be utilized in wound healing and infection control. Nanostructured carbon materials can effectively kill bacteria and prevent the formation of biofilms, which are often resistant to conventional antibiotics. This could potentially revolutionize the treatment of infections, especially those caused by antibiotic-resistant bacteria. Furthermore, carbon nanomaterials have the potential to be used in tissue engineering and regenerative medicine. Their biocompatibility, mechanical strength, and electrical conductivity make them suitable for creating scaffolds to support tissue growth and promote regeneration. Carbon nanomaterials could also be used to enhance the electrical stimulation of tissues, aiding in nerve regeneration and improving the functionality of artificial organs. In addition to these applications, carbon nanomaterials have been explored for their ability to detect and monitor diseases at an early stage. Their unique electronic and optical properties can be utilized in biosensors and diagnostic devices, allowing for sensitive and specific detection of biomarkers associated with various diseases. While the potential uses of carbon nanomaterials in medicine are vast, it is important to note that further research and development are required to ensure their safety, efficacy, and long-term effects. Regulatory considerations and ethical concerns surrounding the use of nanomaterials in medicine also need to be addressed. Nonetheless, the promising capabilities of carbon nanomaterials offer hope for more advanced and personalized medical treatments in the future.

- Q:What is the chemical symbol for carbon?

- The chemical symbol for carbon is C.

- Q:Why does the carbon content of steel increase and the mechanical properties change?

- Steel is an alloy of iron and carbon in 0.04%-2.3% between carbon content. In order to ensure its toughness and plasticity, the main elements in addition to iron, carbon and carbon content is generally not more than 1.7%. steel, and silicon, manganese, sulfur and phosphorus. Classification method of steel variety, there are seven kinds of main methods:1, according to quality classification(1) ordinary steel (P = 0.045%, S = 0.050%)(2) high quality steel (P, S = 0.035%)(3) high quality steel (P = 0.035%, S = 0.030%)2. Classification by purpose(1) building and engineering steel: A. ordinary carbon structural steel; B. low-alloy structural steel; C. reinforced steel(2) structural steelSteel manufacturing machinery: A. (a) quenched and tempered steel; surface hardening (b) steel structure: including carburizing steel, surface hardened steel, with infiltration of ammonia (c) free cutting steel; steel structure; (d) cold forming steel: steel, cold stamping.B. spring steelC. bearing steel(3) tool steel: A. carbon tool steel; B. alloy tool steel; C. high speed tool steel(4) special performance steel: A. stainless acid resistant steel, B. heat-resistant steel, including oxidation resistant steel, hot strong steel, air valve steel, C. electric heating alloy steel, D. wear-resistant steel, e. low temperature steel, F. electrical steel(5) professional steel - such as bridge steel, shipbuilding steel, boiler steel, steel for pressure vessel, steel for agricultural machinery, etc.

- Q:How does carbon affect the properties of steel?

- Carbon affects the properties of steel by increasing its hardness, strength, and overall durability. The presence of carbon allows for the formation of iron carbides, which strengthen the steel's crystal lattice structure. The higher the carbon content, the harder and stronger the steel becomes. However, excessive carbon can make the steel brittle, reducing its impact resistance.

- Q:How does carbon dioxide affect the growth of marine organisms?

- Marine organisms are impacted by carbon dioxide in various ways. To begin with, the ocean's pH can be lowered by increased levels of carbon dioxide, causing ocean acidification. This change in acidity can harm the growth and development of marine organisms, particularly those with calcium carbonate shells or skeletons, such as corals, mollusks, and certain plankton species. Organisms like these may struggle to construct and maintain their structures due to high carbon dioxide levels, rendering them more susceptible to predation and hindering their overall growth and survival. Moreover, the physiology and metabolism of marine organisms can also be affected by elevated carbon dioxide levels. Research suggests that excessive carbon dioxide can disrupt the functioning of enzymes that are responsible for various biological processes, including growth and reproduction. This disruption can result in reduced growth rates, impaired reproductive success, and an overall decline in the fitness of marine organisms. Furthermore, increased carbon dioxide levels can indirectly impact marine organisms by modifying the availability and distribution of other vital nutrients and resources. For instance, heightened carbon dioxide can alter the solubility of minerals and trace elements, impacting their bioavailability to marine organisms. This disruption can disturb nutrient cycling and limit the availability of essential nutrients necessary for growth and development. In summary, the rise in carbon dioxide levels caused by human activities can have significant adverse effects on the growth and development of marine organisms. These effects can disrupt entire marine ecosystems, potentially leading to severe consequences for biodiversity and the functioning of these ecosystems.

- Q:I don't know the battery. Although I know the former is chemical energy, I want to know if the 1 grain size 5 can compare the charge capacity with the 1 grain 5 1ANot much of a fortune, but thank you very much for the enthusiastic friend who gave me the answer. Thank you!

- Note:The above parameter is the mean under the condition that no virtual object is includedAA's battery is size five (diameter 14mm, height 50mm)According to your description, what you mean by "capacitance" is power, which is the actual amount of electricity in the battery.Correct you a misunderstanding, that is, whether it is a one-time battery or lithium battery, rechargeable batteries (nickel hydrogen) are chemical batteries.AA disposable lithium iron batteries have made us resistant and energizer L91, prices in the 2-30 yuan a day before, regardless of the brand and price, the actual consumption of almost all.Hand hit, reference material is "flashlight everybody talks about" Forum

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords