BASF Glue Coated Marble Backing Mesh, 56g/m2

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

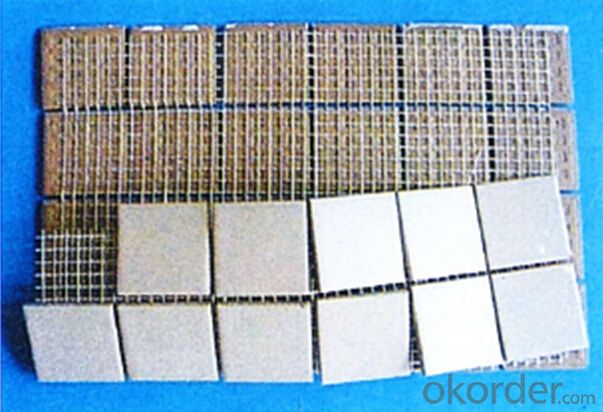

Quick Details of BASF Glue Coated Marble Backing Mesh, 56g/m2

FOB Price of BASF Glue Coated Marble Backing Mesh, 56g/m2 US $0.198 / Square Meter

MOQ of BASF Glue Coated Marble Backing Mesh, 56g/m2: 10000 Square Meters

Supply Ability of BASF Glue Coated Marble Backing Mesh, 56g/m2: 6000000 Square Meters per Month

Payment Terms of BASF Glue Coated Marble Backing Mesh, 56g/m2: L/C,T/T

BASF Glue Coated Marble Backing Mesh, 56g/m2

Specifications of BASF Glue Coated Marble Backing Mesh, 56g/m2

BASF Glue Coated Marble Backing Mesh, 56g/m2 Place of Origin: China (Mainland)

BASF Glue Coated Marble Backing Mesh, 56g/m2 Brand Name: CMAX

BASF Glue Coated Marble Backing Mesh, 56g/m2 Application: Wall Materials

BASF Glue Coated Marble Backing Mesh, 56g/m2 Width: 1M-2M

BASF Glue Coated Marble Backing Mesh, 56g/m2 Size: 5*5/ INCH

BASF Glue Coated Marble Backing Mesh, 56g/m2 Weight: 40gsm to 200gsm

BASF Glue Coated Marble Backing Mesh, 56g/m2 Weave Type: Plain Woven

BASF Glue Coated Marble Backing Mesh, 56g/m2 Yarn Type: C-Glass

BASF Glue Coated Marble Backing Mesh, 56g/m2 Alkali Content: Medium

BASF Glue Coated Marble Backing Mesh, 56g/m2 Standing Temperature: 500℃

Product information of BASF Glue Coated Marble Backing Mesh, 56g/m2

Name: BASF Glue Coated Marble Backing Mesh, 56g/m2

Use best fiberglass yarn and best glue

Clear and beautiful BASF Glue Coated Marble Backing Mesh, 56g/m2

High strength BASF Glue Coated Marble Backing Mesh, 56g/m2

30 years experience of manufacturing BASF Glue Coated Marble Backing Mesh, 56g/m2

Excellent Priced BASF Glue Coated Marble Backing Mesh, 56g/m2

FAQ of BASF Glue Coated Marble Backing Mesh, 56g/m2

Q: What is BASF Glue Coated Marble Backing Mesh, 56g/m2?

Coated Alkali-resistant BASF Glue Coated Marble Backing Mesh, 56g/m2 is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Four years under normal weather conditions and use .

Q: What is the package of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Production periods: 30days for 1X40HQ.

- Q:Glass fiber gridding cloth is easy to be broken after being glued.

- It depends on the glues.

- Q:Double layered alkali-resisting glass fiber gridding cloth

- It is mainly used for alkali resistance, crack resistance and thermal insulation.

- Q:Which parts are the professional mesh of external wall thermal insulation alkali resistant used?

- The use of mesh in the alkali-resistant fiberglass of exterior wall. 1. The function and standard. The main function of the strengthening material of the alkali-resistant fiberglass mesh: To change the mechanical strength of the surface course, ensure the resistance continuality of the finishing layer, and disperse systolic pressure and thermal insulationstress of the surface course. The concentration of the stress should be avoided so as to resist the change of the natural temperature and avoid the crack of the surface course brought by hitting. Whereby the anti-alkali fiberglass mesh plays an important function and role outer insulation system, so to choose the good glass?fiber Mesh is also a great component of the outer insulation system.

- Q:What is the function of the cracking resistant mortar Mesh?

- The cracking resistant mortar Mesh are used for the external wall thermal insulation polystyrene?board, extruded sheet bind and to prevent crack. The recipe is: The cement 350 kg, 700 kg of sand 40-70 purposes, dispersible powder of 15-20 kg, HPMC2 kg, cracking fiber 2-5 kg, 3 kg of lignin, water reducer to 2 kg.

- Q:What is wall gridding cloth and its performance characteristics?

- Wall gridding cloth, also called glass fiber wall gridding cloth or alkali resistant glass fiber, is made of yarn raw material, by coating with acrylic copolymer solution and then drying. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is a new construction material used for strengthening cement plaster wall, crack resistance and thermal insulation of external wall.

- Q:Is there any difference between external wall insulation alkali-resistant fiberglass mesh?

- The main difference between external wallthermal insulation mesh and interior wall mesh is in material. External wall thermal insulation mesh generally employs middle-alkali or alkali-free mesh and as raw materials, and then is formed into alkali resistant mesh after drying when coated with many layers. Then this product is very stable and has great strength,

- Q:What purposes do dry-type transformers epoxy resin mesh have ?

- 1, the product adopts high quality, wax-free, E-glass and electric fiber yarn as the substrate, knitted into a variety of mesh cloth, and is made through heat drying dehydration, and then impregnated with epoxy resin mixture unique formula, dispensing glue under moderate temperature, and heat drying curing. 2, according to the property of the impregnated resin, the products can be divided into solvent and solvent-free mesh mesh. The main differences between the two mesh are as follows: 2.1, impregnated resin is different: Solvent Mesh contains acetone, solvent-free mesh is pure resin. 2.2, different procedures of impregnation: Solvent mesh is impregnated at normal temperature air, and it is opaque; while solvent-free mesh is impregnated under the medium-temperature vacuum pressure, and the mesh is transparent. 2.3, containing different amounts of plastic: The proportion of resin contained in solvent-free mesh is much larger than a solvent mesh, about twice of the solvent mesh. 2.4 application is different: Solvent-free mesh is suitable as an insulating layer between the coils with no partial discharge at very high field intensity the use of solvent-free mesh can reduce the thickness of the interlayer insulation.

- Q:Classification and application of glass fiber

- Glass fiber is a kind of inorganic nonmetallic material with excellent properties. English name is: glass, fiber or fiberglass. Composition of silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide etc.. It is prepared by high temperature melting, wire drawing, winding and weaving process with glass balls or waste glass as. All kinds of products formed finally, glass fiber monofilament diameter from a few microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers are hundreds or even thousands of root root filaments, usually as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy.

- Q:What is the difference in function between alkali-resistant fiberglass mesh and hot dipping galvanized steel mesh?

- They transfer the surface load acting body. When the basis weight of fiberglass mesh increases,you must strictly control the quality of hot dipping galvanized steel to meet the stability of insulation system; the greater tensile bonding strength of brick not only protects the thermal insulation layer, but also the failure surface after drawing is concentrated on the fiberglass mesh, while having good construction operability.

- Q:Waht should be noticed when laying fiber mesh plaster in inner wall? Is it not allowed to lap while laying mesh? Where it is 10cm in doorframe should be paved.

- With the rapid spread of exterior wall insulation technology, there is also something unsatisfied. Currently widely used polyphenyl board thin plaster exterior insulation system has the following disadvantages: 1. Some cracks in the outer surface of the plaster paste polystyrene board exterior insulation work was completed in a relatively short time, the external walls of thin plaster on the table cracks, especially horizontal, vertical seams in polystyrene board, often produce long horizontal cracks and longitudinal cracks. With analysis, the reason of cracking is that the mucilage on plastering layer is too thick and it is not so soft but has large shrinkage; and the other reason is the shrinkage of polyphenyl board. Some construction units has little knowledge about the performance and use requirements of polyphenyl board. These surface cracks affect the appearance of buildings, but also seriously damage the surface layer of protection, affect use function and shorten its service life. 2. Fiberglass mesh is used improperly. In pasting polystyrene board in outer thermal insulation system, fiberglass mesh is to enhance its quality and the quality of construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BASF Glue Coated Marble Backing Mesh, 56g/m2

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords