AR Glass Fiber Chopped Strand for Concrete Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

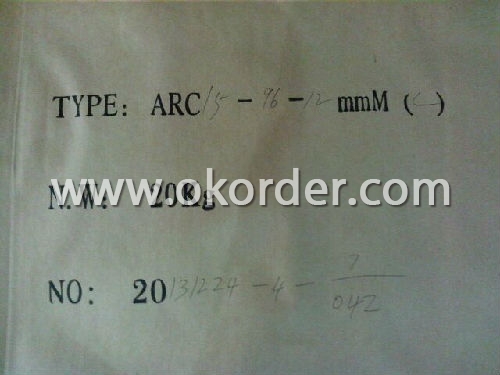

Specifications of AR Glass Fiber Chopped Strand for Concrete:

1. Modest water content

2. Good flowability

3. Even distribution

Instruction of AR Glass Fiber Chopped Strand for Concrete:

AR Glass Fiber Chopped Strand for Concrete is a high integrity AR glassfibre chopped strand designed for use in dry mix systems or other premixing processes for subsequent moulding into a GRC component.

This kind of chopped strand has a sizing system optimised for abrasion resistance and strand integrity during blending with dry materials .The low-tex strand permits efficient reinforcement at low dosages .It is particularly suited to the preparation of pre-bagged mixes of special mortars or renders .It may also be used in the manufacture by precasting of standard GRC components.

Technical Characteristics of AR Glass Fiber Chopped Strand for Concrete:

Tex of strand(tex) | Sizing content(%) | Moisture(%) |

JC/T572-2002 | JC/T572-2002 | JC/T572-2002 |

98±10 | 1.6±0.2 | ≤0.2 |

Package of AR Glass Fiber Chopped Strand for Concrete:

20KG/Paper bag and then put into the Pallet

- Q:I seen on the science channel on like how it works or whatever it was called and they say that this large cube shapped thing of cement could float onnthe ocean to transfer somewhere without any help? Is it possible thanks

- Yes. Lots of boats are made from cement. It all has to do with displacement and shape. Google Ferro Cement Boats.

- Q:how is cement, concrete, mortar and glass made and used?

- Cement is fired blue stone made into a powder. Concrete is portland cement, crushed stone, and sand. Mortar is fired limestone pulverized mixed with sand. Glass is made of silica sand, bicarbonate of soda, and fired to fuse all parts together. Cement is predominately used on stone work and the main ingredient in concrete. Concrete is for swimming pools, walls, sidewalks, patios, etc. Mortar is mostly used to lay brickwork, stucco, plaster, etc. Glass should be self-explanatory.

- Q:Decrease in water/cement ratio will??1)increase in strength 2)Difficult to obtain a smooth finished surface3)Decrease in strength4)Reduction in long term durability Increase in water/cement ratio will??1)Increase in strength 2)Difficult to obtain a smooth finished surface3)Decrease in strength4)Reduction in long term durability

- It is sure that the strength of concrete is directly proportionate to the water cement ratio. Decrease in water cement ratio increase the strength of concrete to some extent, but an optimum ratio is to be maintened so that entire cement part of the concrete can take part in reaction, failing which the concrete will decrease its strength. More over for lesser W/C ratio the workability of the concrete will be affected. So that it is difficult to obtain finishing of your shape. on the contrary, if you increase the W/C ratio it will reduce the strength of concrete. As to react the chemical reaction of cement it required a optimum amount of water. More than that, residual quantity of water will be in the concrete structure. In due course that water will evaporate from the concrete leaving pores in the concrete surface. Which makes the concrete of lesser strength.

- Q:Okay my next orthodontist appointment is on March 11 and on the piece of paper that shows me when my appointment is on the bottom it says band and cement. Is that the whole braces or what?

- I additionally lose interest of individuals here who say Paganism isn't a faith. i comprehend a lot of individuals who think of of themselves as basically 'Pagan'. basically about all of them show satisfaction interior the label. it is likewise almost exclusivly utilized by utilising those individuals who're Eurocentric in our ideals. particular, some comprise Egyptian, African and close by American theory platforms of their spirituality yet will frequently concentration on the platforms originating in Europe. i think a extra accurrate term could be Eclectic Pagan. those are the folk who're not all in favour of attempting to reconstruct an previous faith. they are taking the climate of those faiths that talk to them and coming up a clean faith altogether. a faith referred to as Paganism. lots of what those Pagans have confidence has no foundation in historic actuality. It does not could desire to have any. It stands on my own. this is own. that's what binds Fellowships jointly. i think of the two Pagans and Heathens have each good to call their own faith. no one else can talk for them and say that Paganism nor Heathenism isn't a faith. In 40 years of easily questioning of myself as a Pagan, the only place that factor era has ever been puzzled is stable here in YQA. Princess, i think of what you're discribing isn't lots that individuals think of utilization of the call is advise. i've got confidence individuals grow to be responsive to a brilliant style of Heathens as being very indignant human beings. the extremely some anger could be justified however the theory of anger and intolerance units Heathens apart from the peacefull, tolerant and inclusive attitudes of maximum folk.

- Q:Is the cement industry in the stock a separate plate? Or part of the other plate?

- Follow the concept. The The LZ satisfaction to the too fast, I am very dissatisfied, I believe you have to see my answer will be more satisfied

- Q:I am working in concrete fieled practice and i would like to know more about the cement and microsilica, that is my concern.

- Cement is made by heating limestone [CaCO3] with small quantities of other materials (such as clay) to 1450°C in a kiln, in a process known as calcination. The resulting hard substance [CaO], called 'clinker', is then ground with a small amount of gypsum [MgSO4.2H2O] into a powder to make 'Ordinary Portland Cement', the most commonly used type of cement (often referred to as OPC). Portland cement is a basic ingredient of concrete, mortar and most non-speciality grout. The most common use for Portland cement is in the production of concrete. Concrete is a composite material consisting of aggregate (gravel and sand [impure SiO2]), cement, and water. As a construction material, concrete can be cast in almost any shape desired, and once hardened, can become a structural (load bearing) element. Concrete consists of highly insoluble calcium silicates (CaO+ SiO2 -> CaSiO3). Now silica is pure SiO2 and so finely grounding it and putting into the concrete mixture instead of more coarse sand almost certainly results in a better product with better mixing and hence a stronger cement. This is an educated (I hope!) guess by an inorganic chemist. Cheers, dr p

- Q:How can I dizzolve the cement that the dentist puts in you mouth to seal in a pallet expander? Can i use a house hold fluid? Or can i chip it away? Or what?

- Play it safe an dgo back to the dentist. The cement will dissolve in saliva over a very long period of time. (months to years)

- Q:I used TSP and bleach to clean the floor initially, let it dry overnight, then painted it, let it dry for like a week, and then used a clear cement sealant over top, it's been over a week now and it's still tacky. What can I do?????

- The cement sealer might have reacted with the paint you used. Usually cement sealer is meant for bare cement. Try putting fans on it and if the basement is damp put a dehumidifier in it.

- Q:After walking on a cement floor at work, the next day my knees are killing me, any suggestions as to what kind of shoes to buy?

- Soft rubber soles. They will wear out faster but will save your knees and feet. If you stand in one place very long also add a rubber mat to the floor. The more cushioning the better.

- Q:I want to put the hands on the cement to shape it. I don't want any chemical contamination occuring where the gloves react in any way with the cement.

- If you happen to be allergic to cement (like I am) exposure to the skin can result in burns, abscesses, blisters or secondary infections such as cellulitis (which can lead to amputation of the infected limb or loss of life). Be very careful when handling cement, wet or dry. Wear rubber gloves, eye protection, a respirator and any other personal protective gear you feel is warranted.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing, China |

| Year Established | 1991 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

AR Glass Fiber Chopped Strand for Concrete Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords