Amino Trimethylene Phosphonic Acid Solution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

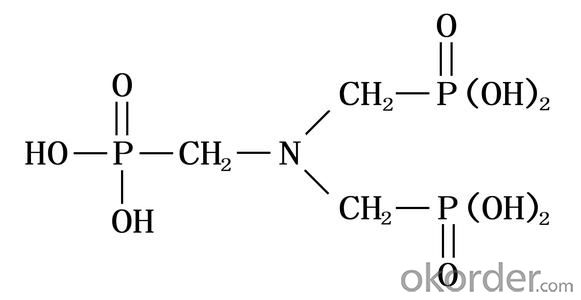

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q:What is positive and negative catalyst in chemistry?

- Positive catalyst can simultaneously speed up the positive and negative reaction rate

- Q:What is the catalyst for high chemistry?

- Concentrated sulfuric acid, NI, barium bromide, copper or silver

- Q:Does a catalyst work for both reactants and products?From my understanding, organic catalyst or enzyme does not necessarily work for the product of the reaction because of the shape of the activation site. However I cannot speak for inorganic ones.

- A catalyst works for either the reactants or the product in a given reaction. If it works for the reactants then the activation site on the enzyme, for example, will only fit on the reactants. If a catalyst is added to a reaction in which it catalyzes the back-reaction, or it aids the products, then the reaction will be reversed. i don't think a catalyst could work for both the reactants and products in one reaction because it wouldn't really be a catalyst anymore; it wouldn't make the rxn progress any faster since it would be canceling out itself by aiding both the reactants and the products. I think this is what you are asking, if not please post more details. I hope I didn't confuse you even more!

- Q:Can the catalyst be a reactant in chemistry?

- There is also a saying that the catalyst participates in the chemical reaction. In a general chemical reaction, the effect of the catalyst is to reduce the activation energy required for the reaction to occur, essentially to turn a more difficult reaction into two, In the second reaction, the catalyst in the first reaction plays the role of the reactant, and the catalyst in the second reaction plays the role of the product, so that the catalyst is not present before and after the reaction Variety.

- Q:What is the catalyst in the end?

- You said the chemical catalyst or Ati graphics card catalyst? If the above is enough to explain the above, if it is the latter, that is, the meaning of the graphics card, Ati's graphics drive like a catalyst

- Q:Does the catalyst participate in chemical reactions?

- In fact, my understanding is to participate in the reaction, but in the whole process of reaction is both a reactant and a product. But in the reaction process is to participate.

- Q:the process of which the heterogeneous catalyst work in vehicles. a step by step instruction in how they work. :)

- The Reduction Catalyst The reduction catalyst is the first stage of the catalytic converter. It uses platinum and rhodium to help reduce the NOx emissions. When an NO or NO2 molecule contacts the catalyst, the catalyst rips the nitrogen atom out of the molecule and holds on to it, freeing the oxygen in the form of O2. The nitrogen atoms bond with other nitrogen atoms that are also stuck to the catalyst, forming N2. For example: 2NO =N2 + O2 or 2NO2 =N2 + 2O2 The Oxidization Catalyst The oxidation catalyst is the second stage of the catalytic converter. It reduces the unburned hydrocarbons and carbon monoxide by burning (oxidizing) them over a platinum and palladium catalyst. This catalyst aids the reaction of the CO and hydrocarbons with the remaining oxygen in the exhaust gas. For example: 2CO + O2 =2CO2

- Q:A substance involved in chemical reflection, but reflects the quality of the material before and after the change, you say it is a catalyst?

- The role of the catalyst is to change the reaction rate of the chemical reaction, which itself does not participate in the reaction! The

- Q:Characteristics and types of catalysts?

- Catalysts don't undergo any change. and types of catalysts - 1) Homogeneous Catalysts ( Having same phase that of reactant, product i.e. reactant and product and catalysts all are either liquid or gas or solid.). 2) Hetrogenrous Catalysts (Different Phase than that of reactant and product. 3) Autocatalysts (reaction proceed catalysed as product is formed or product catalyse the reaction.)

- Q:Could you tell me all the differences between those two catalysts? Thank you very much.

- Biological catalyst: 1. Biological catalysts or enzymes are high molecular weight globular proteins. 2.Their composition may change at the end of reaction. 3.Their catalyzing effect is very high. i.e faster than chemical catalyst. 4.They are reaction specific. i.e One enzyme or biological catalyst may catalyze only particular type of reaction and not many. 5.They are intolerant to temperature and pH changes. An enzyme can not function outside its temperature or pH range. e.g amylase,lipase,pepsin Chemical catalyst: 1.Chemical catalysts are simple inorganic molecules with low molecular weight. 2.They remain unchanged at the end of reaction. 3.They are slower compared to enzymes. 4.They are not reaction specific. 5.They function within wide range of temperatures,pH or pressure. e.g vanadium dioxide, platinum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Amino Trimethylene Phosphonic Acid Solution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products