Aluminum solar moudle frame AA6061

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Material:

Aluminum alloy6061/6063 T3-T8 or follow customer’s demand.( Aluminium profile for PV solar panel frame)

Surface treatment:

1.Anodizing: silver/black mainly and other multicolor.

2.Electrophoresis

3.Powder coating/ PVDF polishing/ sand blasting etc.

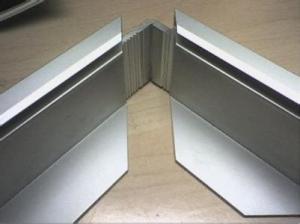

Two types:

1) 90-angle

2) 45-angle

Specifications:

1)30*25mm suitable for 30-120W solar modules.

2)35*35mm suitable for 160-220W solar modules.

3)40*35/45*35/50*35 suitable for 200w above.

The size are available in accordance with customers' requirement.

- Q:Light aluminum is what mean?

- Extruded out only through aging treatment, without other surface treatment of aluminum (such as spraying, oxidation and other deep-processing)

- Q:Are aluminum profiles suitable for balcony railings?

- Yes, aluminum profiles are suitable for balcony railings. Aluminum is a popular material choice for balcony railings due to its durability, strength, and low maintenance requirements. It is resistant to rust and corrosion, making it highly suitable for outdoor use. Additionally, aluminum profiles can be easily customized and shaped to fit any design preference or architectural style. They are lightweight, yet sturdy enough to provide the necessary support and safety for balcony railings. Aluminum railings are also available in a variety of finishes and colors, allowing for endless design possibilities. Overall, aluminum profiles are a reliable and stylish option for balcony railings.

- Q:Can aluminum profiles be used in aerospace applications?

- Yes, aluminum profiles can be used in aerospace applications. Aluminum has been widely used in the aerospace industry for many years due to its various advantageous properties. Aluminum profiles are lightweight, which is crucial in aerospace applications as it helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. Additionally, aluminum profiles possess high strength-to-weight ratio, making them strong enough to withstand the stress and forces experienced during flight. Aluminum is also corrosion-resistant, which is beneficial in the harsh and corrosive environment of aerospace. Furthermore, aluminum profiles can be easily machined and formed into complex shapes, allowing for greater design flexibility. Overall, the combination of lightweight, strength, corrosion resistance, and ease of fabrication makes aluminum profiles an excellent choice for various aerospace applications such as aircraft frames, wings, fuselages, and structural components.

- Q:What are the benefits of using aluminum profiles in interior design?

- Using aluminum profiles in interior design offers several benefits. Firstly, aluminum is a lightweight material, making it easy to handle and install. This allows for flexibility in design, as it can be easily shaped and formed to create unique and intricate patterns. Secondly, aluminum profiles are durable and long-lasting, ensuring that the interior design elements will stand the test of time. They are resistant to corrosion, moisture, and UV rays, making them suitable for various environments, including bathrooms and outdoor spaces. Additionally, aluminum profiles are highly customizable, with a wide range of finishes and colors available. This allows designers to create a cohesive look and feel throughout a space, matching the profiles to other elements such as furniture or fixtures. Furthermore, aluminum profiles are eco-friendly, as they can be recycled and reused. This aligns with sustainable design practices and contributes to reducing environmental impact. Overall, the benefits of using aluminum profiles in interior design include their lightweight nature, durability, versatility, customization options, and eco-friendliness, making them an excellent choice for creating stylish and long-lasting interior spaces.

- Q:Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers several advantages in these applications. One of the main benefits of using aluminum profiles in railway and transportation infrastructure is their low weight. Aluminum is significantly lighter than other materials like steel, making it easier to transport and install. This weight reduction can also lead to energy savings, as less fuel is required to move the infrastructure elements. Additionally, aluminum profiles have a high strength-to-weight ratio, meaning they can withstand heavy loads while still being relatively lightweight. This makes them suitable for various structural applications, such as supporting overhead power lines, constructing platforms, and forming the framework for bridges and tunnels. Aluminum also has excellent corrosion resistance, which is crucial in railway and transportation infrastructure exposed to harsh weather conditions and environmental elements. Aluminum profiles can withstand moisture, UV rays, and other corrosive agents, reducing maintenance requirements and increasing the lifespan of the infrastructure. Moreover, aluminum profiles can be easily fabricated and customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for flexibility in design and construction. Aluminum profiles can also be easily joined together using different methods, such as welding or fastening, providing ease of assembly and disassembly if needed. In conclusion, aluminum profiles can indeed be used in railway and transportation infrastructure. Their lightweight, high strength, corrosion resistance, and versatility make them an excellent choice for various structural and functional applications in these sectors.

- Q:How are aluminum profiles cut and shaped?

- Depending on the desired result, there are various methods available for cutting and shaping aluminum profiles. One popular approach involves the use of saws. Whether it's a hand saw or a power saw like a miter saw or circular saw, specially designed blades capable of cutting through aluminum are utilized. Alternatively, CNC (Computer Numerical Control) machines provide a highly precise option. By programming these machines, aluminum profiles can be cut and shaped with great accuracy. This technique is particularly suitable for intricate and complex designs. Shaping aluminum profiles can be achieved through different techniques as well. For instance, bending is a common method. Specialized bending machines apply force gradually to achieve the desired angle without causing any damage or deformation to the aluminum. Another shaping technique is extrusion. This involves forcing the aluminum through a die to create a specific shape. Extrusion is commonly employed in the manufacturing of aluminum profiles with consistent cross-sectional shapes like tubes or beams. Overall, achieving the desired results in cutting and shaping aluminum profiles necessitates the use of specialized tools and machinery. The specific method chosen depends on the complexity of the design and the desired outcome.

- Q:What are the features of the poor aluminum profiles?

- Low precision, bad feel, and so on, some inferior shape.You'd better go to the manufacturer you trust.

- Q:Which is the highest price of aluminum profile 60616063?

- Generally speaking, 6061 of a little higher, but also depends on the quality, whether there is aging treatment, such as T6 status;6063, low silicon content, relatively soft, oxidation effect is better than 6061, suitable for appearance pieces, LED lamp holder, etc.; 6061, cutting performance is good, suitable for structural parts.

- Q:How do aluminum profiles perform in terms of dimensional stability?

- The excellent dimensional stability of aluminum profiles is widely recognized. This stability is attributed to the inherent characteristics of aluminum, including its low coefficient of thermal expansion and its high strength-to-weight ratio. As a result, these profiles are able to maintain their shape and dimensions even when subjected to varying temperatures and loads. This reliability makes them a preferred choice for industries such as construction, automotive, and aerospace, where precise and consistent dimensions are crucial. Moreover, the extrusion process allows for the production of aluminum profiles with precise tolerances, further enhancing their dimensional stability. All in all, aluminum profiles deliver outstanding performance in terms of dimensional stability, ensuring that the desired specifications remain intact over time.

- Q:Aluminum Alloy rail safety glass balcony design, Aluminum Alloy profiles for what is standard specifications?

- The specifications and sizes of aluminum doors and windows are mainly marked by the height dimension of the section of the profiles (used in aluminium alloy doors and windows, and the thickness of the door and window frames), and form a series of dimensions. Aluminum doors and windows profiles are 40, 45, 50, 55, 60, 65, 70, 80, 90, 100mm and other dimensional series. Among them, the size of aluminum alloy window is smaller, and the size of aluminum alloy door is larger.1, aluminum doors and windows dimensioning the same series, not necessarily aluminum windows and doors section shape and size are the same. The aluminum alloy door and window profiles of the same size series are quite complex in shape and size. Must be analyzed and treated in accordance with the drawings.2 、 the aluminum door and window profile is divided into solid section and hollow section according to the shape of the section, and the application of the hollow profile is larger.3, aluminum doors and windows profiles of wall thickness, for aluminum alloy window of not less than 1.4mm, with aluminum alloy door is not less than 2mm.4, aluminum door and window profiles of length, size, dividing ruler, double ruler and indefinite ruler three kinds. Fixed length generally not more than 6m, variable length is not less than 1m.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum solar moudle frame AA6061

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords