Aluminum Sheets AA1050 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

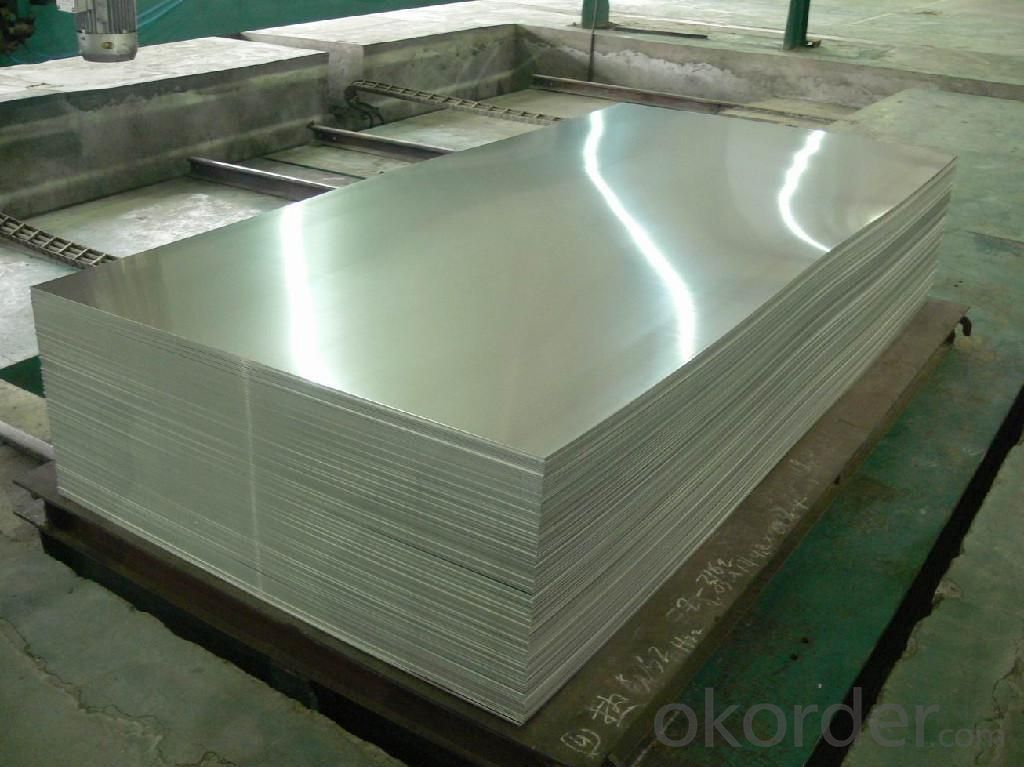

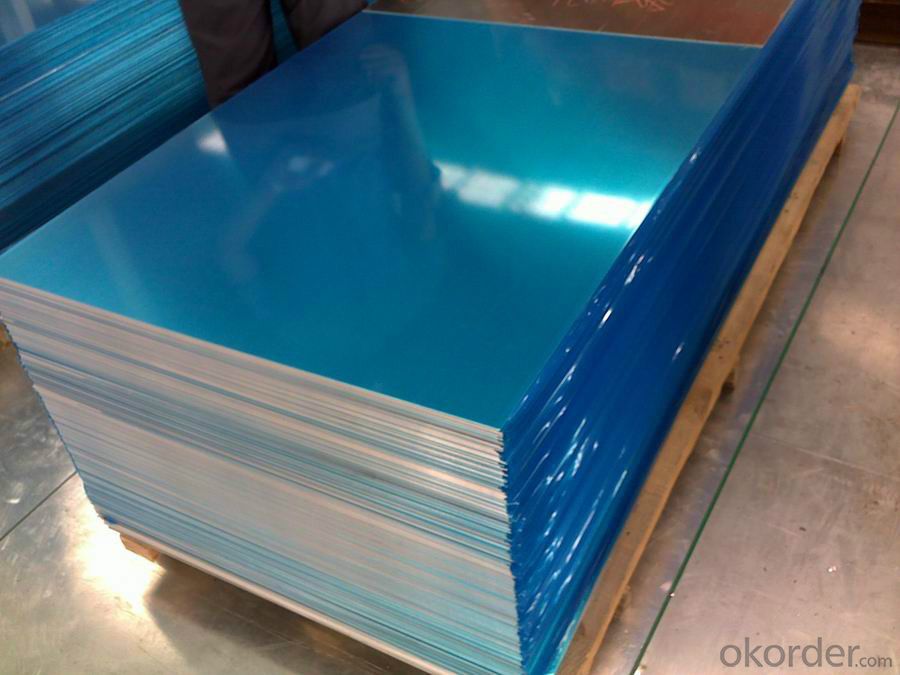

1.Structure of Aluminum Sheets AA1050 Used for Construction Description

Aluminum Sheets AA1050 Used for Construction is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets AA1050 Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA1050 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1050 Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Sheets AA1050 Used for Construction Images

4.Aluminum Sheets AA1050 Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1050 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1050 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1050 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

C.What is the MOQ?

The MOQ for each size is 4-5 tons.

- Q:what's the difference between zinc sheet and aluminum sheet?

- Only zinc sheet can react, zinc is amphoteric.

- Q:What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q:Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are highly suitable for manufacturing kitchen utensils. Aluminum is a lightweight and durable material that offers excellent heat distribution properties. It is corrosion-resistant, making it ideal for contact with food and liquids. Additionally, aluminum is non-reactive, which means it does not leach any harmful substances into the food being cooked or stored. It is also easy to clean and maintain, making it a popular choice for kitchen utensils. Overall, aluminum sheets are a reliable and efficient option for manufacturing a wide range of kitchen utensils.

- Q:What are the different methods of surface protection for aluminum sheets?

- Aluminum sheets can be protected in various ways to ensure their longevity and functionality. Anodizing is a widely used technique, involving the creation of a protective oxide layer on the aluminum surface. This is achieved by immersing the sheets in an electrolyte solution and passing an electric current through them. The outcome is a resilient and corrosion-resistant layer that can be further enhanced with different dyes and sealants. Another option is powder coating, which entails applying a dry powder onto the aluminum sheets and then curing it with heat. This results in a robust coating that offers excellent defense against scratches, chemicals, and weathering. Powder coating is available in a wide array of colors and finishes, making it a popular choice for decorative purposes. Chemical conversion coating is yet another alternative, involving the treatment of aluminum sheets with a chemical solution to convert the surface into a protective layer. This coating not only improves corrosion resistance but also provides a suitable base for paint or other coatings. Painting is a commonly utilized method for safeguarding aluminum sheets. Different types of paints, such as epoxy, acrylic, and polyurethane-based coatings, can be applied to the surface. These paints not only shield against corrosion and environmental factors but also offer the opportunity for aesthetic customization. Lastly, laminating is a technique where a protective film is applied to the surface of the aluminum sheets. These films can be made from various materials like PVC, polyester, or polyethylene. Laminating adds an extra layer of protection against scratches, abrasion, and UV radiation. Each method of surface protection for aluminum sheets has its own merits and considerations, which depend on the specific requirements of the application. It is crucial to thoroughly assess the desired level of protection, aesthetic preferences, and budget constraints before selecting the most suitable method.

- Q:Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

- Q:Can 101 aluminum sheets be stamped or engraved?

- Certainly! Stamping or engraving 101 aluminum sheets is indeed possible. Aluminum, being a highly adaptable material, lends itself well to different manipulation techniques. Stamping entails exerting pressure to imprint a design or pattern onto the aluminum sheet, whereas engraving involves carving or incising a design onto it. Both methods can be applied to aluminum sheets, including those composed of 101 aluminum alloy. Nevertheless, it is crucial to take into account the thickness and hardness of the sheets, as these variables might impact the precision and sharpness of the stamped or engraved design.

- Q:Can aluminum sheets be used for reflective surfaces?

- Indeed, reflective surfaces can be crafted using aluminum sheets. Renowned for its exceptional reflectivity, aluminum proves to be an ideal material for producing such surfaces. With its sleek and impeccably polished texture, aluminum sheets efficiently bounce back light, heat, and various types of radiation. This remarkable attribute renders them suitable for an extensive array of purposes, encompassing solar panels, mirrors, lamp reflectors, and reflective insulation. Utilizing aluminum sheets as reflective surfaces offers numerous advantages, including their enduring nature, lightweight composition, and resistance to corrosion.

- Q:Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a popular material choice for food packaging due to its unique properties. It is lightweight, flexible, and has excellent barrier properties, which means it can effectively protect food products from moisture, light, oxygen, and other external contaminants. Aluminum sheets are commonly used for packaging various food items such as beverages, canned goods, ready-to-eat meals, and snacks. Additionally, aluminum is also recyclable, making it an environmentally friendly choice for food packaging.

- Q:Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q:How does aluminum sheet perform in outdoor applications?

- Aluminum sheet performs exceptionally well in outdoor applications due to its inherent corrosion resistance and durability. It is highly resistant to rust and can withstand exposure to harsh weather conditions, making it ideal for outdoor structures, signage, and cladding. Additionally, aluminum sheets can be coated or painted to enhance their weather resistance and aesthetic appeal. Overall, aluminum sheet is a reliable and long-lasting material for various outdoor applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheets AA1050 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords