Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Aluminum sheet is also known as Treadplate, Floor Plate, Chequer Plate, Checkered Plate, Chequered Floor Plate, Checker Plate and Check Plate. It is made of anti-corrosion aluminum alloy stock, rolled with special and beautiful embossing shape. It has the property of anti-sliding, anti-corrosion, easy cleaning and high mechanical strength.

l Specification

| Product | aluminum sheet |

| Thickness | 0.2mm-350mm |

| Popular Thickness | 0.3mm/0.4mm/0.6mm/0.8mm/1.0mm/2.0mm/3.0mm/4.0mm/6.0mm/8.0mm.... |

| Width | 800mm-2000mm |

| Popular size | 1000*2000,1200*2400,1219*2438,1220*2440 1000*3000,1250*3000,1500*3000 etc. |

| weight | 1500kg-2000kg |

Material | 1050, 1060, 1100, 3003, 3004, 3105, 5052, 5005, 5754, 5083, 6061, 6063 etc |

| Temper | O, H12, H14, H16, H18, H24, H26, H32, H34, H111, H112, T3, T5, T6 etc |

| Surface | mill finished |

| Coated | PE ,PVDF |

lPackaging & Delivery

Packaging detail: wooden cases that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

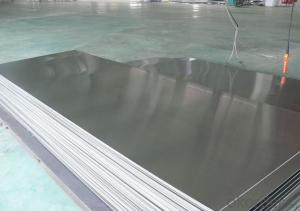

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q:Are aluminum sheets fire resistant?

- In reality, fire resistance characterizes aluminum sheets. With a high melting point and difficulty in igniting or burning, aluminum emerges as a non-combustible substance that hinders fire propagation. Consequently, aluminum sheets find extensive utilization in sectors like construction and aerospace, where fire resistance assumes paramount importance. Nevertheless, it is crucial to acknowledge that although aluminum inherently possesses fire resistance, the materials or substances affixed to or in contact with the aluminum sheet might lack such properties.

- Q:iron-based alloys over aluminum in structural members of bridges and buildings?

- Strength-to-weight ratio.

- Q:i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- Aluminum sulfate lowers the pH of soil (increases the acidity). To increase the pH, you need to add lime. The ideal pH for most plants is around neutrality, or pH = 7. I can't tell you how much lime to add, since I don't know how much aluminum sulfate you added. Try to add roughly the same amount as the aluminum sulfate and see if that helps. Overwatering may help some, as it will leach out some of the acid.

- Q:I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- If this is your first bow, I'd say go aluminum. Get the Platinum Plus from Easton, much cheaper and a hell of a lot better build than carbon arrows twice its price. The key with aluminum is to choose shafts with thick walls. When you look at the shaft sizes, you have a 4 digit number. The first 2 digits represents the outer diameter of the shaft, while the second 2 digits represents the wall thickness. With Plats, you want to get something with a 16 wall thickness. That's 16/1000, so 1516 or 1716 etc. The size/stiffness of these shafts will depend on 2 major factors, and 1 not so major one. The major factors are drawlength and draw weight at that drawlength. The one other factor is the bow design and material. Certain newer top end limbs will be so fast that they need stiffer arrows compared to older bows of the same drawweight. Now, carbon shafts, carbon shafts break yes, but it's your responsibility to make sure before you shoot to check for micro cracks. To do that, you bend the arrow and turn the shaft while listening for cracking noises. Well built carbon shafts will last a very long time, but well built carbon arrows are also at least 3 times more expensive than the Plats. Some durable arrows include the Gold Tip, and the Carbon Express. Not all carbon arrows are built to be durable mind you. Some are built for speed sacrificing durability. So, my vote is get yourself a set of Platinums, these shafts, while cheap had been the world record holder for a rather long time at 18m and 25m.

- Q:on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q:How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q:the aluminium pull tabs are in a jucy juice bottle

- So saving pull tabs isn't a complete waste of time. But let's make one thing clear: *there's nothing special about pull tabs*. You'd save yourself a heap o' trouble and make a lot more money if you recycled the whole can. The Reynolds and kidney foundation people have tried to get that point across with a poster showing a red Ghost busters-type slash through a cartoon of someone trying to detach a pull tab from a can. The headline says, Keep Tabs on Your Cans. But the public hasn't gotten the message. Supposedly responsible people -- e.g., the honchos at your school -- will organize pull tab collection drives without even bothering to get the whole story. Urban legends expert Jan Brunvand reports that in 1989 a Minneapolis VFW post organized a pull tab collection drive for the local Ronald McDonald House. When Brunvand asked the organizers why they didn't tell people to save whole cans, they lamely replied that there were hygiene problems and that people liked mailing in the tabs, even though the postage often exceeded the value of the aluminum. In other words, it's not important to *do* good as long as people *feel* good. Sometimes I don't think we have enough common sense in this country to fill a teacup.

- Q:What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q:How does the thickness tolerance of aluminum sheet affect its usability?

- The usability of aluminum sheet is greatly influenced by its thickness tolerance, which refers to the acceptable deviation from the specified thickness. This tolerance is typically expressed as a range or a plus/minus value. Having a tighter thickness tolerance guarantees that the aluminum sheet consistently meets the desired specifications. This is crucial in industries such as aerospace, automotive, and construction, where precise dimensions are necessary. Even a slight deviation in thickness can have a negative impact on the performance and functionality of the product. For example, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is of utmost importance. A thin sheet could compromise the structural integrity, while a thicker sheet could add excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is vital to ensure compatibility and fitment of various components. On the other hand, a looser thickness tolerance may be acceptable in applications where precise dimensions are not as critical. For instance, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Furthermore, manufacturing aluminum sheets with tighter thickness tolerances generally incurs higher costs due to increased precision and quality control measures. Therefore, the desired level of tolerance should be carefully balanced with the intended use and cost considerations. To conclude, the usability of aluminum sheet is directly influenced by its thickness tolerance, particularly in industries that require precise dimensions. Selecting the appropriate tolerance level is essential to ensure that the sheet meets the necessary specifications and maintains the desired performance and functionality of the final product.

- Q:how to find 0.6mm waste strake of aluminum sheet?

- ask door and window maker for some strake.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords