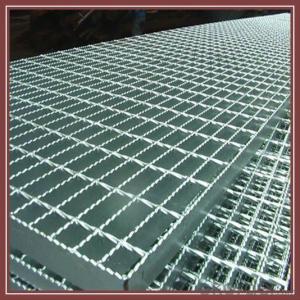

Aluminum Gratings/Grates/Grate Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can aluminum sheets be used as heat shields?

- Aluminum sheets are capable of being used as heat shields. The reason for this is that aluminum possesses exceptional thermal conductivity, enabling it to effectively conduct and transfer heat away from its source. Moreover, aluminum exhibits a high melting point, which enables it to endure high temperatures without distorting or warping. These characteristics render aluminum sheets an optimal selection for heat shield purposes, which encompass safeguarding delicate components and structures from heat-related harm in various industries such as automotive, aerospace, and industrial sectors. Additionally, aluminum is lightweight and comparatively easy to mold, which makes it a practical alternative for heat shields that necessitate installation in confined areas or intricate designs. In summary, utilizing aluminum sheets as heat shields provides efficient thermal protection while offering durability, versatility, and cost-effectiveness.

- Q:Are the aluminum sheets available in different grades?

- Indeed, there are various grades of aluminum sheets obtainable. Aluminum is widely utilized in different sectors owing to its lightweight, resistance to corrosion, and impressive strength-to-weight ratio. To cater to diverse applications, distinct grades of aluminum sheets have been tailored. Among the frequently encountered grades are 1100, 3003, 5052, 6061, and 7075. Each grade possesses distinctive qualities and attributes, encompassing strength, formability, weldability, and machinability. The selection of a grade relies on factors like the intended purpose, environmental circumstances, and desired characteristics of the end product.

- Q:Can aluminum sheet be welded?

- Indeed, welding aluminum sheet is feasible. Aluminum, a versatile metal, lends itself well to welding through the utilization of diverse techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). Nevertheless, the welding of aluminum necessitates specific considerations due to its elevated thermal conductivity and low melting point when compared to other metals. Consequently, selecting the suitable welding process, filler material, and shielding gas is crucial to ensuring a successful weld. Moreover, proper surface preparation, including thorough cleaning and the removal of any oxide layer, plays a pivotal role in achieving a robust and long-lasting weld in aluminum sheet.

- Q:What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper, as well as the manufacturing process. However, on average, the tensile strength of aluminum ranges from around 70 to 700 MPa (megapascals). This makes aluminum a relatively strong material compared to other non-ferrous metals. It is important to note that the tensile strength can also be influenced by factors such as the thickness and shape of the aluminum component, as well as any heat treatment it has undergone. Therefore, it is always recommended to consult specific data sheets or engineering references for accurate and precise information regarding the tensile strength of a particular aluminum alloy.

- Q:Can aluminum sheets be used for automotive body panels?

- Certainly, automotive body panels can indeed utilize aluminum sheets. In reality, the automotive industry is progressively incorporating aluminum due to its lightweight attributes and remarkable strength-to-weight ratio. By employing aluminum sheets for body panels, the overall weight of the vehicle is diminished, thereby enhancing fuel efficiency and performance. Moreover, aluminum exhibits exceptional resistance to corrosion, rendering it an enduring selection for automotive purposes. The use of aluminum sheets for automotive body panels has gained considerable popularity, particularly in the manufacturing of electric vehicles, as their lightweight structure optimizes the vehicle's range.

- Q:What are the common thicknesses of aluminum sheets used in construction?

- The common thicknesses of aluminum sheets used in construction vary depending on the specific application and requirements. However, some commonly used thicknesses include 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are often used for architectural applications such as wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), are also used in heavier construction applications such as structural components, support beams, and decking. It is important to note that these thicknesses are just examples and can vary depending on the specific project requirements and engineering specifications.

- Q:which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Aluminum The density of Aluminum is pretty low. Gold has a very high density, almost twice as dense as iron. Density = mass / volume

- Q:I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- the aluminum voice coils will get louder than the copper coils but the sensitivity is lower.ok, say you have one hdc3 copper and hdc3 aluminum.with a 1000 watts rms or smaller amplifier the copper coils will get louder.but if you go with a larger amplifier,say 1500 watts rms or more the aluminum coils will be louder.

- Q:Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q:Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Gratings/Grates/Grate Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords