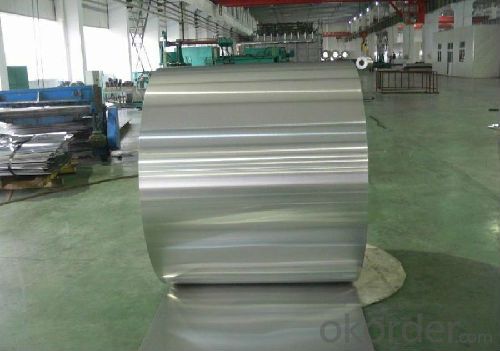

Aluminum Coil and Sheet 1050 1100 3003 H14 H24 O

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Coil Discription

1. | Item | aluminum coil | |

2. | Standard | ASTM B221M, GB/T 3191, JIS H4040, etc. | |

3. | alloy | 1050 1200 1060, 1100, 1200, 3003, 3004 | |

4. | Temper | O H12 H14 H16 H18 H19 H22 H24 H26 H28 | |

5. | Specifications | thickness | 0.2--10mm |

Width | 90--2200mm | ||

Coil ID | 505mm 508mm 605mm 405mm 610mm 300mm | ||

6. | Surface | Mill finish, polished, mirror finish anodizing, brushing, sand blasting, powder coating, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

12. | Contact | If you have any question, please feel free contact CNBM. | |

Chemistry Composition & Mechanical Properties

Chemistry Composition of aluminum coil | |||||||||

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | 0.050 | 0.030 | 99.5 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | - | 0.050 | 0.030 | 99.6 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | 0.040 | 0.030 | 99.7 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.0 | |

1200 | Si+Fe:1.00 | 0.050 | 0.050 | - | - | 0.100 | 0.100 | 99.0 | |

1145 | Si+Fe:0.55 | 0.050 | 0.050 | 0.050 | - | 0.050 | - | 99.45 | |

3003 | 0.600 | 0.700 | 0.05-0.20 | 1.0-1.5 | - | - | 0.100 | - | remains |

3004 | 0.300 | 0.700 | 0.250 | 1.0-1.5 | 0.8-1.3 | - | 0.250 | - | remains |

Packaging & Shipping

1. The aluminum coil will be lined with plastic bags and kraft paper for againsting moisture.

2. The carton paper will be put out of the carton paper.

3. Using fuming strong wooden pallets to load the aluminum coil.

4. Steel belt to fix the aluminum coil steadily on the wooden pallets.

- Q:Can aluminum sheets be laminated?

- Indeed, it is possible to laminate aluminum sheets. Lamination involves the fusion of multiple layers to form a composite material that exhibits improved properties. Aluminum sheets, for instance, can undergo lamination with diverse substances like plastics, adhesives, or even alternative metals. This method has the potential to enhance the strength, durability, as well as the thermal and electrical conductivity of the aluminum sheets. The resultant laminated aluminum sheets find widespread application in numerous industries, including construction, automotive, aerospace, and packaging. This utilization is driven by the ability of the amalgamation of distinct materials to confer tailored characteristics suitable for specific purposes.

- Q:Are aluminum sheets suitable for use in automotive or aerospace industries?

- Yes, aluminum sheets are suitable for use in both the automotive and aerospace industries. Aluminum is widely used in these industries due to its lightweight yet strong properties, corrosion resistance, and good thermal and electrical conductivity. It is commonly used in the construction of vehicle bodies, aircraft frames, and various aerospace components.

- Q:which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q:What are the common thicknesses of aluminum sheets used in transportation industry?

- Aluminum sheets are widely utilized in the transportation sector for various purposes due to their lightweight, durability, and ability to resist corrosion. In this industry, the thickness of aluminum sheets typically falls within the range of 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). When it comes to automotive body panels, which necessitate a balance between weight reduction and structural integrity, the preferred thickness of aluminum sheets is usually between 0.040 inches (1.02 mm) and 0.063 inches (1.6 mm). These particular thicknesses ensure sufficient strength while effectively reducing the overall weight of the vehicle compared to steel counterparts. In the aerospace field, where weight reduction is of utmost importance, thinner aluminum sheets are commonly employed. Typically, thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are used in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is important to note that the specific thicknesses of aluminum sheets in the transportation industry may vary depending on the particular application, regulatory requirements, and design factors. Thus, it is crucial to consult the relevant industry standards and specifications for accurate information regarding the recommended thicknesses for different transportation applications.

- Q:Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes due to their malleability and ductility.

- Q:Are 101 aluminum sheets suitable for agricultural machinery?

- Indeed, agricultural machinery finds suitability in a total of 101 aluminum sheets. Aluminum, a material that is both versatile and lightweight, brings forth numerous advantages for agricultural machinery. Its outstanding resistance to corrosion becomes particularly vital for equipment that confronts diverse weather conditions and chemicals commonly encountered in the agricultural industry. Furthermore, the strength-to-weight ratio of aluminum proves to be advantageous, permitting an augmented payload capacity and enhanced fuel efficiency. Moreover, the malleability of aluminum allows manufacturers to fashion intricate shapes and designs for machinery components. All in all, the durability, corrosion resistance, and versatility demanded by agricultural machinery are adequately met by 101 aluminum sheets.

- Q:Can aluminum sheets be used for electrical enclosures?

- Certainly! Electrical enclosures can make use of aluminum sheets. Aluminum is a favored option for such enclosures owing to its impressive conductivity, resistance against corrosion, and lightweight characteristics. It serves as an effective electrical conductor, enabling efficient distribution of current within the enclosure. Furthermore, aluminum exhibits exceptional resistance to corrosion, rendering it appropriate for outdoor and challenging environments. Its lightweight nature also simplifies handling and installation processes. All in all, aluminum sheets prove themselves as dependable and frequently employed materials for electrical enclosures.

- Q:What does 1060h/24 mean in aluminium alloy?

- Each digit in the 1060-H24 stands for the following meanings:First, a number of Arabia 1 is representative of pure aluminum (aluminum is aluminum content above 99% aluminum, in addition to the beginning and start with 2-8 are 2### for copper and aluminum magnesium alloy, 3### aluminum manganese alloy, 4### alloy, 5### alloy and so on)Two, second, Arabia number 0, said the original alloy, such as 1, said the original alloy after a modification, 2 means that the original alloy after two modificationsThree, third and four 60 two Arabia data represent the value behind pure aluminum content of 99% per cent in pure aluminum, said 60 pure aluminum aluminum content of 99.60%, as the standard 1050 indicates the aluminum content of pure aluminum, 99.50% of the 1070 said that the aluminum content of 99.70% pure aluminum alloy in the back. In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q:What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment process. Generally, aluminum sheets have a relatively low surface hardness compared to other metals such as steel or titanium. However, certain aluminum alloys can be heat-treated to improve their hardness. For example, 6061-T6 aluminum sheets have a surface hardness of around 95 Brinell, while 7075-T6 aluminum sheets have a surface hardness of approximately 150 Brinell. It is important to note that these values are approximate and can vary depending on the specific alloy, temper, and processing conditions.

- Q:What's the standard thickness of aluminum sheet?

- the thickness of tobacco aluminum foil and red wine bottle cap is designed according to customers demands and manufacturer has no stated specification.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil and Sheet 1050 1100 3003 H14 H24 O

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords