Aluminium Sheet With Best Stocks Price In Warehouse

- Loading Port:

- Qingdao

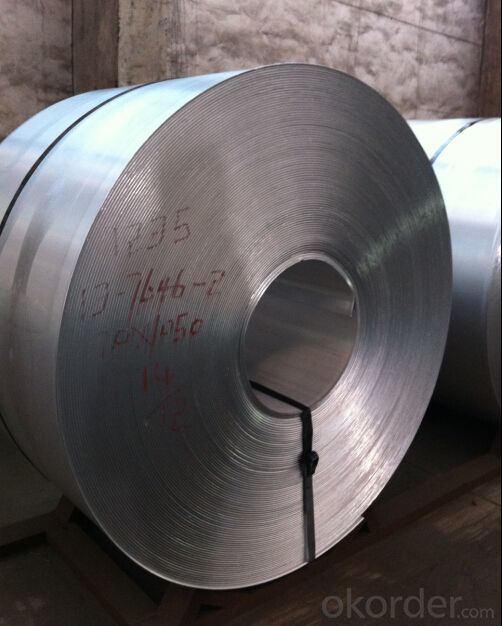

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Product Description

aluminum shees with cold rolled and hot rolled plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 8000series, 7000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1100,3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1000mm*2500mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 7 tons/each size.

How many tons did you export in one year

USA, Japan,UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally they are checkered aluminum sheet with big-5-bar and small-5-bar pattern,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q:How much is one ton of aluminium plate?

- Aluminum sheet is more than 0.2mm thickness, 500mm, 200mm width, length of less than 16m aluminum material called aluminum sheet or aluminum sheet, 0.2mm below is aluminum, 200mm within the width of row or strip material! Aluminum prices look at what specifications you want, what material, you can consult the Guangdong Hon Hai metal

- Q:What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary depending on several factors, such as the alloy composition, heat treatment, and manufacturing processes. However, in general, aluminum alloys are known for their relatively low hardness compared to other metals. The Rockwell hardness scale is commonly used to measure the hardness of metals, but it is not typically applied to aluminum. Instead, the Brinell or Vickers hardness tests are more commonly used for aluminum alloys. Without specific information about the alloy composition and any specific heat treatment applied to the 101 aluminum sheets, it is difficult to provide an exact hardness rating. Therefore, it is recommended to consult the manufacturer or supplier of the specific 101 aluminum sheets for accurate hardness information.

- Q:How does the formability of aluminum sheet vary with different alloys?

- The formability of aluminum sheet can vary significantly with different alloys due to variations in their chemical composition and mechanical properties. Aluminum alloys are typically alloyed with other elements such as copper, manganese, magnesium, and zinc to enhance specific characteristics such as strength, corrosion resistance, and formability. Some aluminum alloys, such as the 1xxx series (pure aluminum) and the 3xxx series (alloyed with manganese), have excellent formability and are often used for deep drawing applications. These alloys can be easily formed into complex shapes without cracking or tearing. On the other hand, alloys with higher strength properties, such as the 2xxx series (alloyed with copper) and the 7xxx series (alloyed with zinc), typically have reduced formability. These alloys are often used in structural applications where strength is crucial, but they may require more careful handling and processing to avoid cracks or other defects during forming. Alloys in the 5xxx series (alloyed with magnesium) generally offer a good balance of formability and strength. They are widely used in various industries, including automotive and aerospace, for their ability to be easily formed into different shapes while providing adequate strength and corrosion resistance. It is important to note that the formability of aluminum sheet is not solely determined by the alloy composition but also influenced by other factors such as the thickness of the sheet, the temperature during forming, and the specific forming process employed (e.g., deep drawing, bending, stretching). These factors can interact with the alloy properties to affect the formability characteristics of aluminum sheet. Therefore, it is essential to carefully select the appropriate alloy and process parameters to achieve the desired formability for specific applications.

- Q:What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q:Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- This Site Might Help You. RE: Aluminum Foil on Windows for summer heat or what works? Does Aluminum Foil really work to help beat the summer heat? I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just...

- Q:If not, where can i buy some aluminum?

- some contraptions do not use radio waves, a CD participant as an occasion. Radio waves are flying around everywhere, and can intervene with a number of the comfortable singals interior those contraptions, so we want a thank you to dam the waves. some contraptions produce radio-waves, not as an meant output of the gadget, yet as a byproduct of yet another function. Your computing device is an occasion of this. And those contraptions can intervene with the operation of contraptions that are interior attain, like your cellular telephone. So we could give up those by probability produced waves from getting out of the computing device. and in specific circumstances a factor of a gadget makes use of radio waves on a similar time as yet another area of a similar gadget would not, and could be shielded from the different area or it won't artwork right.

- Q:Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q:And isn't aluminum extremely bad for ones health?

- Antiperspirant does two things. It kills sanitizes the area so it kills resident bacteria that eat the oils and secretions in the skin and produce odor. The aluminum compounds plug the pores and prevent sweat secretion. But be careful, aluminum has been implicated in Alzheimers disease.

- Q:I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- Aluminum okorder /... Read both pages. The information is basic enough to be useful no matter where you live.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet With Best Stocks Price In Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords