Aluminium Sheet for Circle Cutting for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Sheet for Circle Cutting for Cookware Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Sheet for Circle Cutting for Cookware:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

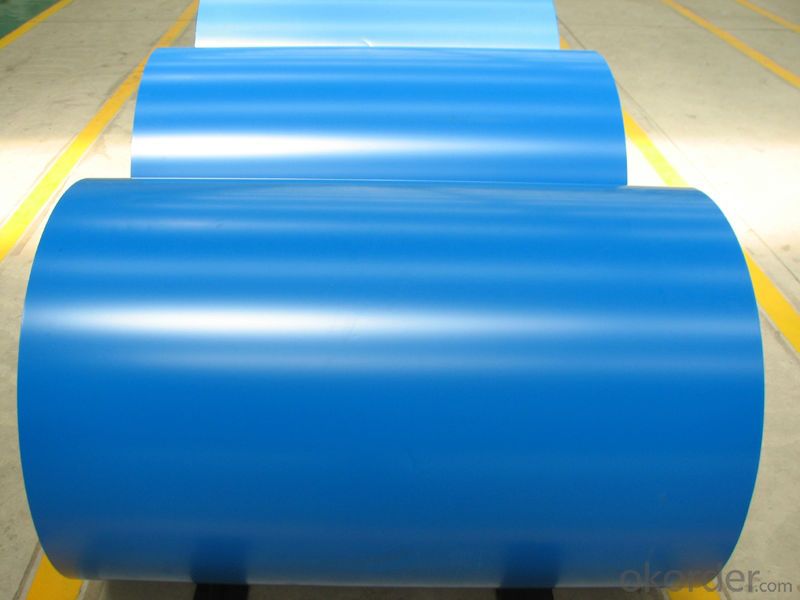

Images of the Aluminium Sheet for Circle Cutting for Cookware:

Aluminium Sheet for Circle Cutting for Cookware Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:What are the different surface treatments available for aluminum sheets?

- Aluminum sheets have several surface treatment options, each with its own unique properties and advantages. Anodizing, painting, powder coating, and laminating are some of the most commonly used methods. Anodizing, a popular technique, involves immersing the aluminum sheet in an electrolyte solution and passing an electric current through it. This creates a protective oxide layer on the surface, enhancing corrosion resistance, durability, and offering decorative finishes in various colors. Painting is another frequently chosen treatment. It involves applying a layer of paint to the sheet, improving aesthetics and providing protection against corrosion and environmental factors. Painting allows for a wide range of colors and finishes, making it versatile for different applications. Powder coating is an electrostatic process where a dry powder is applied to the aluminum sheet and then cured under heat. This creates a durable and attractive finish with excellent resistance to weathering, chemicals, and UV rays. It offers a variety of color options, textures, and finishes suitable for outdoor use. Laminating involves bonding a thin layer of a different material, like plastic or wood, onto the aluminum sheet. This enhances aesthetics and provides additional properties such as scratch resistance, increased strength, and insulation. Laminating offers a wide range of finishes and textures, allowing for customization and design versatility. These examples demonstrate the various surface treatments available for aluminum sheets. The choice of treatment depends on specific application requirements, desired aesthetics, durability, and environmental factors. Seeking guidance from a professional or supplier can assist in determining the most suitable surface treatment option for a particular project or application.

- Q:Are the aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are highly suitable for architectural applications. Aluminum is a versatile material that offers numerous benefits for architectural projects. It is lightweight, durable, and resistant to corrosion, making it ideal for exterior applications. Aluminum sheets can be easily shaped, formed, and manipulated to create intricate designs and structures, allowing architects to bring their creative visions to life. Additionally, aluminum is a sustainable material as it is 100% recyclable, reducing the environmental impact of architectural projects. Overall, the use of aluminum sheets in architectural applications provides both aesthetic appeal and functional durability, making it a preferred choice for architects and designers.

- Q:have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

- Q:What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on their thickness and dimensions. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter.

- Q:What are the different types of alloys used for painted aluminum sheets?

- Painted aluminum sheets commonly utilize various types of alloys. Among them, 3003 stands out as a favored option due to its exceptional corrosion resistance and high formability. This alloy finds extensive use in industries like automotive, where a smooth surface finish is preferred. Another frequently employed alloy is 5052, which provides superior strength compared to 3003. Its remarkable resistance to corrosion and ability to endure harsh environments make it suitable for marine and architectural applications. Moreover, it is renowned for its weldability and formability. 6061 is also a well-liked choice for painted aluminum sheets. Its notable attributes include high strength and excellent machinability. This alloy is often employed in structural applications, such as the production of aircraft parts and automotive components. Furthermore, painted aluminum sheets may incorporate other alloys like 2024, 5754, and 7075. These alloys possess specific properties that render them suitable for particular applications, such as elevated strength or improved corrosion resistance. In essence, the selection of the alloy for painted aluminum sheets hinges upon the specific requirements of the application, such as desired strength, corrosion resistance, and formability.

- Q:How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Q:Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q:Can the aluminum sheets be used for manufacturing food storage containers?

- Yes, aluminum sheets can be used for manufacturing food storage containers. Aluminum is a popular choice for food storage containers because it is lightweight, durable, and has excellent thermal conductivity. It can easily be formed into various shapes and sizes, making it suitable for different types of food storage needs. Additionally, aluminum is resistant to corrosion and can be easily cleaned, ensuring the safety and hygiene of the stored food.

- Q:Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q:Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Let's fix it for you. We can't do the coil. We do hot plated pure aluminum steel plate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet for Circle Cutting for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords