Aluminium Sheet,Aluminium Price Per Kg 2024 5052 5083 6061 7075

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

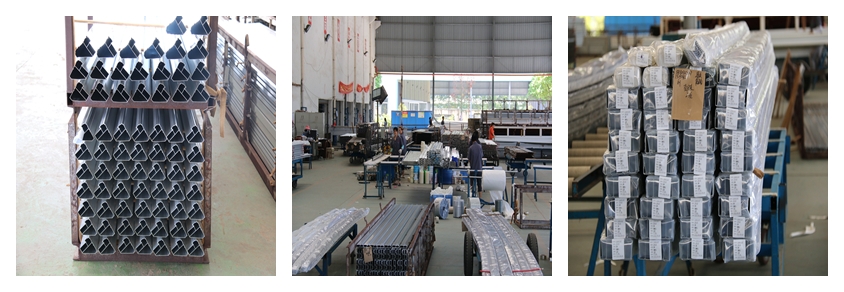

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q:What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications due to their unique properties. Some typical uses for 101 aluminum sheets include: 1. Automotive industry: 101 aluminum sheets are widely used in the automotive industry for manufacturing vehicle bodies, panels, and other components. Their lightweight nature, corrosion resistance, and high strength-to-weight ratio make them ideal for improving fuel efficiency and reducing overall vehicle weight. 2. Construction industry: These aluminum sheets are extensively used in construction projects for roofing, cladding, and facades. They provide excellent durability, weather resistance, and easy formability, making them suitable for various architectural applications. 3. Packaging industry: 101 aluminum sheets are commonly used in the packaging industry for manufacturing cans, containers, and foils. Their malleability and ability to retain the freshness and quality of food make them a preferred choice for packaging perishable goods. 4. Electrical industry: Due to their excellent conductivity and low electrical resistance, 101 aluminum sheets are frequently used in the electrical industry for manufacturing power transmission lines, bus bars, and electrical enclosures. They offer superior heat dissipation properties, making them ideal for applications requiring efficient heat transfer. 5. Marine industry: The corrosion-resistant properties of 101 aluminum sheets make them suitable for marine applications. They are often used in boat building, shipbuilding, and offshore structures, as they can withstand the harsh saltwater environment without significant degradation. 6. Aerospace industry: 101 aluminum sheets find extensive use in the aerospace industry for manufacturing aircraft components such as wings, fuselages, and structural parts. Their lightweight nature and high strength make them crucial for reducing the overall weight of aircraft and increasing fuel efficiency. 7. Household appliances: These aluminum sheets are commonly used in the manufacturing of household appliances like refrigerators, air conditioners, and cookware. Their thermal conductivity, durability, and resistance to corrosion make them suitable for various applications in the home. Overall, 101 aluminum sheets have a wide range of uses and applications across various industries due to their exceptional properties, including lightweight, corrosion resistance, durability, and formability.

- Q:What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary, depending on the specific alloy and temper.

- Q:Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q:What is aluminum curtain wall.

- Shell nosing edge sealing cap

- Q:1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q:Are aluminum sheets suitable for food-grade applications?

- Indeed, food-grade applications can utilize aluminum sheets. Due to its exceptional attributes, aluminum is extensively employed in the food industry. It is known for being non-toxic, resistant to corrosion, and possessing a high level of thermal conductivity. Consequently, it proves to be a fitting option for both food processing and packaging. Not only can aluminum sheets be utilized in the creation of food-grade containers, trays, and packaging materials, but they are also commonly employed in cooking utensils. For instance, baking sheets and foil made from aluminum are safe to use when in direct contact with food. Moreover, aluminum sheets are easily cleaned and sanitized, thereby making them a hygienic choice for food-grade applications.

- Q:What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q:Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q:Can aluminum sheets be used for bus bodies?

- Indeed, bus bodies can be constructed using aluminum sheets. Aluminum, renowned for its lightweight and durable qualities, is frequently utilized in the fabrication of bus bodies. Its exceptional strength-to-weight ratio renders it an optimal selection for bus manufacturers, as it enhances fuel efficiency and expands payload capacity. Moreover, aluminum exhibits remarkable resistance to corrosion, a valuable attribute for vehicles perpetually confronted with diverse weather conditions. Additionally, aluminum can be effortlessly shaped and fabricated, enabling the production of intricate forms and designs. Consequently, aluminum sheets are widely favored for bus bodies owing to their robustness, lightness, resistance to corrosion, and adaptability.

- Q:Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- I've ridden old Cannondales for years. I've never heard a horror story, if anything it is overengineered. With any frame, you need to see if there is any damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet,Aluminium Price Per Kg 2024 5052 5083 6061 7075

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords