Aluminium Profile for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile for Industrial Material Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Industrial Material :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

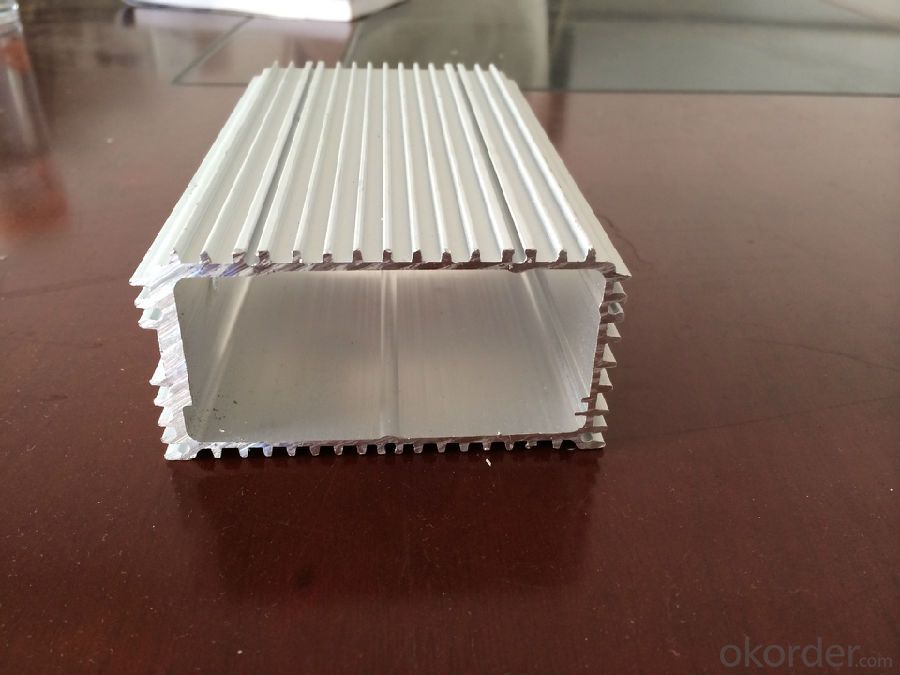

3.Aluminium Profile for Industrial Material Images:

4.Aluminium Profile for Industrial Material Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:30*40 how much aluminum meter?

- 3040 aluminum price, looking for Shanghai Bei pie. Aluminum specifications are complete, the corresponding parts are.

- Q:Can aluminum profiles be used in modular exhibition system manufacturing?

- Yes, aluminum profiles can be used in modular exhibition system manufacturing. Aluminum profiles are known for their lightweight and durable properties, making them ideal for constructing modular exhibition systems. They are easy to handle and assemble, allowing for quick and efficient installation and dismantling of exhibition booths. Additionally, aluminum profiles can be easily customized and reconfigured to meet specific design requirements, making them a versatile choice for modular exhibition system manufacturing.

- Q:in addition to the groove width is not the same as other well differentiated? Is there any difference in wall thickness?

- There must be a difference. There is a distinction between rice weight and wall thickness. For example, Jing Teng Aluminum CompanyJT-8-5050W meters weight is 3.25KG,,JT-10-5050 meters weight is 2.95KG. Specific parameters, you can go to consult the next business

- Q:Aluminum blackening formula

- Anodic oxidation of aluminum is aluminum or Aluminum Alloy anode to lead as cathode in sulfuric acid, oxalic acid, chromic acid and aqueous solution electrolysis, so that the surface oxide film. The anodic oxidation process is most widely used. Aluminum and Aluminum Alloy sulfuric acid anodizing oxidation film has high adsorption capacity, easy sealing alone or with colored more to improve the corrosion resistance of anodic oxide film thickness and appearance. The process is generally Aluminum Alloy sulfuric acid anodizing electrolyte has the advantages of simple operation, stable, cost is not high, the process is mature, but in sulfuric acid anodized process often unavoidable failure occurred, influence of oxide film quality. The following detailed analysis about the failure reasons, then give some preventive measures for your reference:Common faults and analysisAluminum Alloy products by sulfuric acid anodic oxidation, partial oxidation without touch, showing visible black spots or stripes, film drums or holes. The failure phenomenon of tumor is rare but has occurred.Dr. al website has detailed knowledge

- Q:What are the different sizes and dimensions of aluminum profiles?

- Various industrial and construction needs can be met with aluminum profiles, which are offered in a wide range of sizes and dimensions. These profiles are available in different shapes, including angles, channels, beams, tubes, and bars, each with its own unique dimensions. Angle profiles, for example, can be found in sizes ranging from 1/2 inch to 6 inches, with thickness measurements that vary from 1/16 inch to 1/2 inch. These profiles are commonly utilized for structural applications, reinforcements, and framing. For channel profiles, dimensions range from 1/2 inch to 8 inches, with thickness measurements varying between 1/8 inch to 1/2 inch. These profiles are often used for framing, support structures, and edge protection. Beam profiles have varying dimensions, including heights that range from 1 inch to 12 inches and flange widths from 1 inch to 6 inches. The thickness of these profiles can range from 1/8 inch to 1/2 inch. Beam profiles are frequently employed for load-bearing applications, such as bridges, buildings, and heavy machinery. Tube profiles come in various sizes, including outer diameters ranging from 1/2 inch to 12 inches and wall thicknesses between 1/16 inch to 1/2 inch. These profiles are commonly utilized in applications requiring fluid transportation, structural support, and decorative purposes. Lastly, aluminum bars are available in different dimensions, such as widths ranging from 1/8 inch to 6 inches and heights from 1/8 inch to 2 inches. The thickness of these bars can vary from 1/8 inch to 1/2 inch. Aluminum bars are commonly used for structural support, framing, and decorative purposes. It is important to keep in mind that these dimensions are not exhaustive and may vary based on the manufacturer and specific project requirements. It is recommended to consult with the manufacturer or supplier to determine the exact sizes and dimensions available for a specific aluminum profile.

- Q:What is the opening section of aluminum profile?

- The opening position and the closed position are corresponding to the open section bar and the closed section section. Closed form refers to the outer contour of a profile forming a closed box shaped body; the opening is an outer contour without closure or no full closure. However, many practical profiles are more complex, with closed parts and open parts, which naturally produce "opening parts" and "closed parts"".The minimum column section thickness of the main stress parts, mainly referring to the national standard "Aluminum Alloy" building material GB/T5237 on the wall with a minimum thickness profile for 3.0mm, for the closed box section, with good resistance to local instability of the performance, can use a smaller wall thickness, the minimum wall thickness 2.5mm profiles, thus allowing.

- Q:Are aluminum profiles suitable for playground equipment?

- Playground equipment can be made from aluminum profiles, which are lightweight and durable materials commonly used in many industries, including playground equipment manufacturing. These profiles are known for their strength and resistance to corrosion, making them perfect for outdoor use. They provide stability and can handle the weight and forces exerted during play. In addition, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the equipment. The versatility of aluminum allows for the creation of various shapes and designs, offering endless possibilities for innovative and attractive playground structures. In summary, aluminum profiles are an ideal choice for playground equipment due to their strength, durability, and safety features.

- Q:How many tons of aluminum can be produced by a ton of aluminium ingots?

- There are many factors to consider in this problem, and in the case of insufficient conditions, we can only compare them by using the hypothesis method. But personally think that a meal of aluminum ingots can definitely make a full or more than a ton of aluminum. The product is Aluminum Alloy, pure aluminum processed into Aluminum Alloy, so the process is sure to add other metal components (such as silicon, iron, copper, manganese, magnesium, zinc, chromium, titanium), assuming that the pure aluminum ingots is one hundred percent, so in the process of loss amount the amount of aluminum must be smaller than the metal, so the results will come out

- Q:What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- Alloy composition is different, 6061 of the other alloy composition is much higher than 6063.

- Q:Are there any materials for aluminum profiles?

- According to alloy compositionCan be divided into 1024, 2011, 6063, 6061, 6082 and 7075 grade aluminum alloy, which is the 6 most common. Grades are different in various metal components ratio is not the same, except for the commonly used aluminum profile doors and windows such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual drawings of customers.By surface treatment1. anodized aluminum2. electrophoresis coating aluminum material3. powder spraying aluminum material4. wood grain transfer aluminum5. fluorocarbon spraying aluminium material6., polishing aluminum (divided into mechanical polishing and chemical polishing two kinds, in which the highest cost of chemical polishing, the price is also the most expensive)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords